54

NOTE: DO NOT set medium--heat manifold pressure less than

1.3-- in. wc or more than 1.7 --in. wc for natural gas.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in reduced furnace

life.

DO NOT bottom out gas valve regulator adjusting screws.

This can result in unregulated manifold pressure and result

in excess overfire and heat exchanger failures.

CAUTION

!

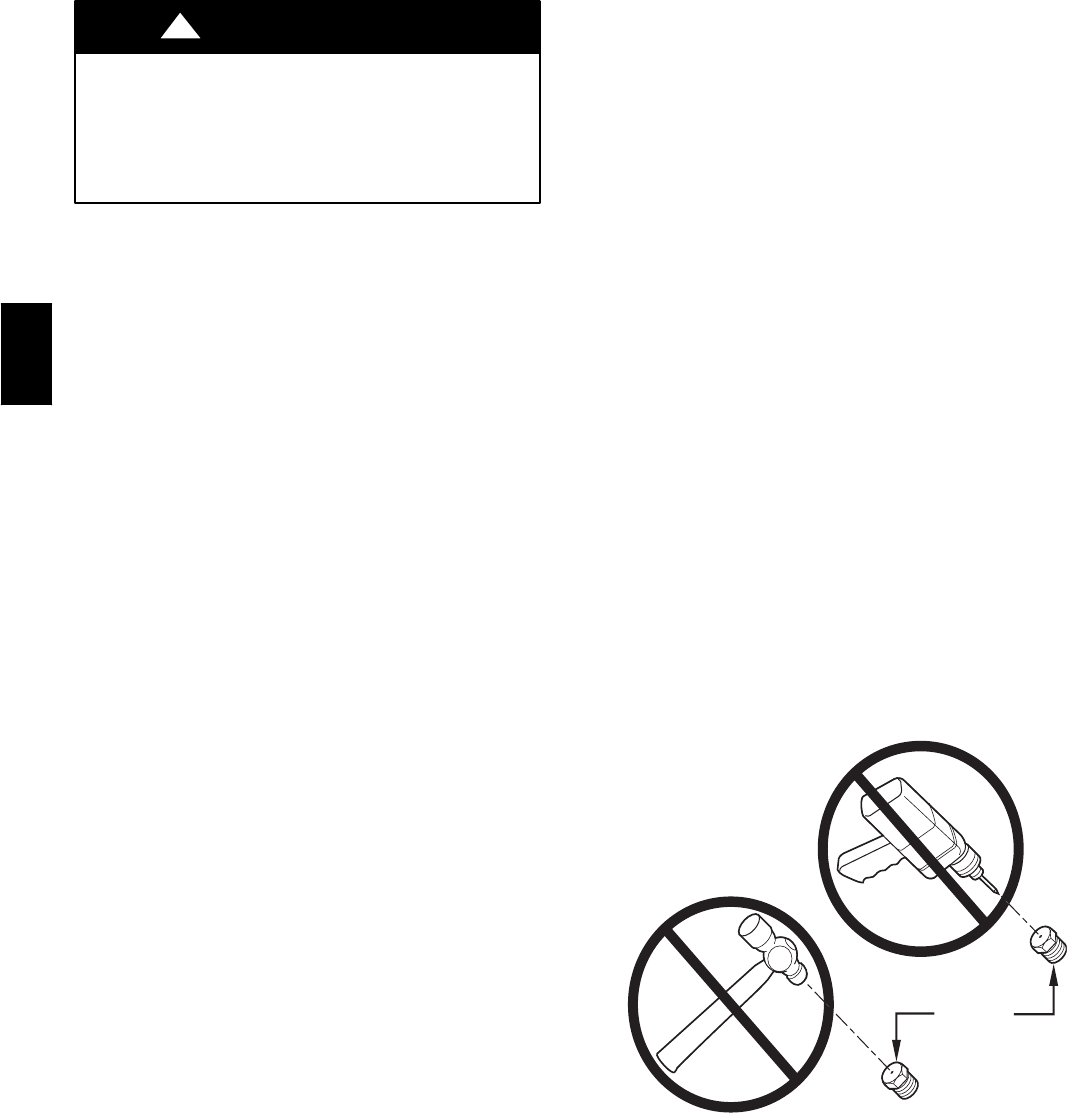

NOTE: If orifice hole appears damaged or it is suspected to have

been redrilled, check orifice hole with a numbered drill bit of

correct size. Never redrill an orifice. A burr--free and squarely

aligned orifice hole is essential for proper flame characteristics.

(See Fig. 61.)

f. Move setup switch SW4--2 to OFF position after

completing medium--heat adjustment.

g. Jumper Rand W/W1and W2thermostatconnectionson

furnace control. (See Fig. 33.) This keeps furnace locked

in high --heat operation.

h. Turn high--heat adjusting screw counterclockwise (out)

to decrease manifold pressure or clockwise (in) t o

increase manifold pressure.

NOTE: DO NOT set high--heat manifold pressure less than

3.2--in. wc or more than 3.8 --in. wc for natural gas.

i. Remove jumpers R to W/W1 and R to W2.

j. Wait for blower off--delay to finish then reset 115--v

power to furnace.

k. Jumper R and W/W1 thermostat connections on control

to start furnace.

l. Wait for the blower to turn ON then check low--heat

manifold pressure. It should be between .5 to .6--in. wc.

This setting should not require adjustment but if it does

remove the low--heat adjustment cap (See Fig. 60) and

turn the low--heat adjusting screw clockwise (in) to

decrease manifold pressure or counterclockwise (out) to

increase manifold pressure. You will only have 15

minutes to make an adjustment if needed. I f you need

more time then move setup s witch SW1--2 on control

center to ON position (See Fig. 33).

NOTE: DO NOT set low--heat ma nifold pressure before setting

medium--heat manifold pressure. DO NOT set low--heat manifold

pressure less than .5 --in. wc or more than .6 --in. wc for natural

gas.

m. When correct manifold pressures are obtained, replace

caps that conceal gas valve adjustment screws. Main

burner flame should be clear blue, almost transparent.

(See Fig. 62.)

n. Remove jumper across R and W/W1. If necessary move

setupswitchSW1--2totheOFFposition.

3. Verify natural gas input rate by clocking gas meter.

NOTE: Be sure all pressure tubing, combustion --air and vent

pipes, and burner enclosure front are in place when checking

input by clocking gas meter.

a. Calculate high--altitude adjustment (if required).

UNITED STATES

Ataltitudesabove2000ft,thisfurnacehasbeenapproved

for 2 percent derate for each 1000 ft abovesea level. See

Table 11 for derate multiplier factor and example.

CANADA

Atinstallation altitudesfrom 2000to4500ft,thisfurnace

must be derated 5 percent by an authorized Gas

Conversion Station orDealer.To determine correctinput

rate for altitude, see example and use 0.95 as derate

multiplier factor.

EXAMPLE: 80,000 BTUH HIGH--HEAT INPUT

FURNACE INSTALLED AT 4,300 FT

Furnace Input Rate at Sea Level X Derate Multiplier

Factor = Furnace Input Rate at Installation Altitude

80,000 X 0.91 = 72,800

b. Reinstall burner box cover.

NOTE: Clocking gas input rate MUST always be performed

with the burner box cover INSTALLED.

c. Check that gas valve adjustment caps are in place for

proper input to be clocked.

d. Obtain average heat value (at altitude) from local gas

supplier.

NOTE: Be sure heating value of gas used for calculations is

correct for your altitude. Consult local gas utility for altitude

adjustment of gas heating value.

e. Check and verify orifice size in furnace. NEVER

ASSUME THE ORIFICE SIZE. ALWAYS CHECK

AND VERIFY.

f. Turn of f all other gas appliances and pilots.

g. MovesetupswitchSW4 --2toONposition.(SeeFig.33.)

This keeps furnace locked in medium-- heat operation.

BURNER

ORIFICE

A93059

Fig. 61 -- Burner Orifice

355CAV