4

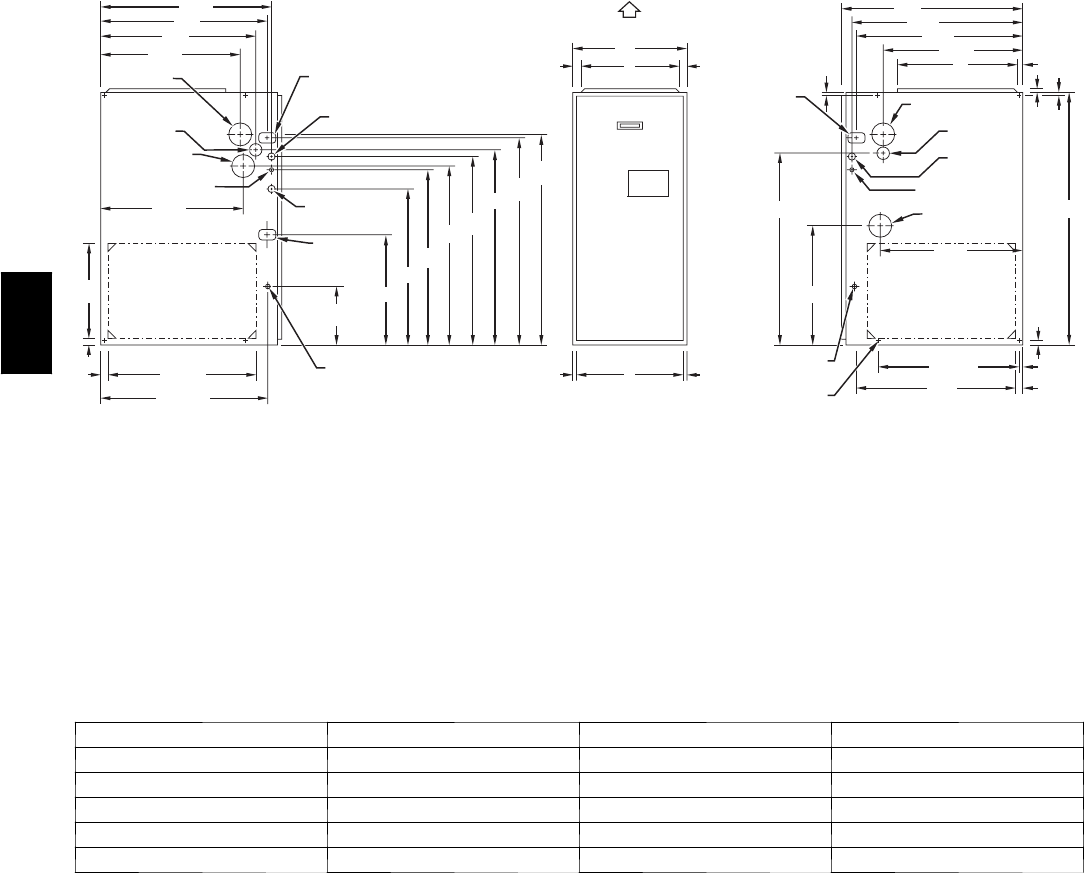

NOTES: 1. Minimum return-air openings at furnace, based on metal duct. If flex duct is used,

see flex duct manufacturer’s recommendations for equivalent diameters.

2. Minimum return-air opening at furnace:

a. For 800 CFM–16-in. round or 14

1

/2

x 12-in. rectangle.

b. For 1200 CFM–20-in. round or 14

1

/2

x 19

1

/2

-in. rectangle.

c. For 1600 CFM–22-in. round or 14

1

/2

x 23

1

/4

-in. rectangle.

d. For airflow requirements above 1800 CFM, see Air Delivery table in Product Data

literature for specific use of single side inlets. The use of both side inlets, a

combination of 1 side and the bottom, or the bottom only will ensure adequate

return air openings for airflow requirements above 1800 CFM.

17

5

⁄

16

"

24

1

⁄

2

"

27

9

⁄

16

"

TYP

27

5

⁄

8

"

29

11

⁄

16

"

TYP

30

13

⁄

16

"

32

5

⁄

8

"

TYP

33

1

⁄

4

"

TYP

CONDENSATE

DRAIN TRAP

LOCATION

(ALTERNATE

UPFLOW)

7

⁄8-IN. DIA

ACCESSORY

POWER ENTRY

7

⁄8-IN. DIA

POWER CONN

CONDENSATE DRAIN

TRAP LOCATION

(DOWNFLOW &

HORIZONTAL LEFT)

26

15

⁄

16

"

24

1

⁄

2

"

22

5

⁄

16

"

2-IN. COMBUSTION-

AIR CONN

1

⁄2-IN. DIA

GAS CONN

2-IN. VENT CONN

1

⁄2-IN. DIA THERMOSTAT

ENTRY

22

11

⁄

16

"

SIDE INLET

23

1

⁄

4

" TYP

SIDE INLET

1

1

⁄

4

"

1"

OUTLET

26

15

⁄

16

"

28

1

⁄

2

"

22

5

⁄

16

"

19"

13

⁄

16

"

5

⁄

8

"

5

⁄

16

"

1"

39

7

⁄

8

"

22

1

⁄

4

" TYP

11

⁄

16

"

7

⁄

16

"

24

3

⁄

16

"

BOTTOM INLET

18

1

⁄

4

"

22

11

⁄

16

"

2-IN. COMBUSTION-

AIR CONN

1

⁄2-IN. DIA

GAS CONN

7

⁄8-IN. DIA

POWER CONN

1

⁄2-IN. DIA

THERMOSTAT ENTRY

2-IN. VENT CONN

DIMPLE LOCATORS

FOR HORIZONTAL

HANGING

14

1

⁄

2

"

TYP

SIDE INLET

9

7

⁄

16

"

TYP

26

15

⁄

16

" TYP

CONDENSATE

DRAIN LOCATION

(UPFLOW)

30

1

⁄

2

"

9

⁄

16

"

TYP

CONDENSATE

DRAIN LOCATION

(UPFLOW)

E

INLET

11

/

16

"

11

/

16

"

D

13

/

16

"

13

/

16

"

OUTLET

A

AIRFLOW

26

1

⁄

4

"

26

1

⁄

4

"

CONDENSATE DRAIN

TRAP LOCATION

(DOWNFLOW &

HORIZONTAL RIGHT)

OR ALTERNATE

1

⁄

2

-IN. DIA GAS CONN

A05124

Dimensions (In. / mm)

UNIT SIZE A D E

042060 17---1/2 / 444.5 15---7/8 / 403.2 16 / 406.4

042080 21 / 533.4 19---3/8 / 492.1 19---1/2 / 495.3

060080 21 / 533.4 19---3/8 / 492.1 19---1/2 / 495.3

060100 21 / 533.4 19---3/8 / 492.1 19---1/2 / 495.3

060120 24---1/2 / 622.3 22---7/8 / 581.0 23 / 584.2

Fig. 2 -- Dimensional Drawing

A gas--fired furnace for installation in a residential garage must be

installed as specified in the Hazardous Locations section of these

instructions and Fig. 5.

The furnace may be used for construction heat provided that the

furnace installation and operation complies with the first

CAUTION in the LOCATION section of these instructions.

This gas furnace may be used for construction heat provided that:

S The furnace is permanently installed with all electrical

wiring, piping, air filters, venting and ducting installed

according to these installation instructions. A return air

duct is provided, sealed to the furnace casing, and ter-

minated outside the s pace containing the furnace. This

prevents a negative pressure condition as created by the

circulating air blower, causing a flame rollout and/or

drawing combustion products into the structure.

S The furnace is controlled by a thermostat. It may not be

“hot wired” to provide heat continuously to the struc-

ture without thermostatic control.

S Clean outside air is provided for combustion. This is to

minimize the corrosive effects of a dhesives, sealers and

other construction materials. It also prevents the en-

trainment of drywall dust into combustion air, which

can cause fouling and plugging of furnace components.

S The temperature of the return air to the furnace is

maintained between 55_F(13_C) and 80_F(27_C),

with no evening setback or shutdown. The use of the

furnace while the structure is under construction is

deemed to be intermittent operation per our installation

instructions.

S The air temperature rise is within the rated rise range on

the furnace rating plate, and the firing rate has been set

to the nameplate value.

S The filters used to clean the circulating air during the

construction process must be either changed or

thoroughly cleaned prior to occupancy.

S The furnace, ductwork and filters are cleaned as

necessary to remove drywall dust and construction

355CAV