53

NOTE: Reference Fig. 52--59:

1. Heat pump MUST have a high pressure switch for dual

fuel applications.

2. Refer to outdoor equipment Installation Instructions for

additional information and setup procedure.

3. Select the “ZONE” position on the two--speed heat pump

control.

4. Outdoor Air Temperature Sensor must be attached in all

dual fuel applications.

5. Dip switch No.1 on Thermidistat should be set in OFF

position for air conditioner installations. This is factory

default.

6. Dip switch No. 1 on Thermidistat should be set in ON

position for heat pump installations.

7. Dip switch No. 2 on Thermidistat should be set in OFF

position for single--speed compressor operation. This is

factory default.

8. Dip switch No. 2 on Thermidistat should be set in ON

position for two--speed compressor operation.

9. Configuration Option No. 10 “Dual Fuel Selection” must

be turned ON in all dual fuel applications.

10. NO connection should be made to the furnace HUM

terminal when using a Thermidistat.

11. Optional connection. If wire is connected to W2 on

furnace control board, either dip switch SW1--2 or SW4--2

on furnace control should be set in ON position to allow

Thermidistat/Thermostat to control furnace at 2 stages

Low/High or Medium/High.

12. Optional connection. If wire is connected, ACRDJ jumper

on furnace control should be removed to allow

Thermidistat/Thermostat to control outdoor unit staging.

13. Furnace must control its own staging operation via furnace

control algorithm. This is factory default.

14. The RVS Sensing terminal “L” should not be connected.

This is internally used to sense defrost operation.

15. DO NOT SELECT the “FURNACE INTERFACE” or

“BALANCE POINT” option on the two --speed heat pump

control board. This is controlled internally by the

Thermidistat/Dual Fuel Thermostat.

16. Dip switch D on Dual Fuel Thermostat should be set in

OFF position for single--speed compressor operation. This

is factory default.

17. Dip switch D on Dual Fuel Thermostat should be set in

ON position for two--speed compressor operation.

Step 4 — Adjustments

Set Gas Input Ra te

Furnace gas input rate on rating plate is for installations at

altitudes up to 2000 ft.

In the U.S.A., the input rating for altitudes above 2000 ft must be

reduced by 2 percent for each 1000 ft above sea level.

In Canada, the input rating must be derated by 5 percent for

altitudes of 2000 ft to 4500 ft above sea level.

Adjust manifold pressure to obtain input rate.

Furnace input rate must be within +2 percent of input rate on

furnace rating plate.

1. Determine natural gas orifice size and manifold pressure

for correct input.

a. Obtainaverageheatvalue(at installedaltitude)fromlocal

gas supplier.

b. Obtain average specific gravity from local gas supplier .

c. Verify furnace model. Table 10 can only be used for

model 355CAV Furnaces.

d. Find installation altitude in Table 10.

NOTE: For Canadian altitudes of 2000 to 4500 ft, use U.S.A.

altitudes of 2001 to 3000 ft in Table 10.

e. Find closest natural gas heat value and specific gravity

in Table 10.

f. Follow heat value and specific gravity lines to point of

intersection to find orifice size and low--, medium--, and

high--heat manifold pressure settings for proper

operation.

EXAMPLE: (0 -- 2000 ft altitude)

Heating value = 1050 Btu/cu ft

Specific gravity = 0.62

Therefore: Orifice No. 45

Manifold pressure: 3.8 --in.wcfor high heat1.6 --in.wcformedium

heat 0.6--in. wc for low heat

* Furnace is shipped with No. 45 orifices. In this example, all main

burnerorifices arethe correct size and do not need to be changed to

obtain proper input rate.

g. Check and verify burner orifice size in furnace. NEVER

ASSUME ORIFICE SIZE; ALWAYS CHECK AND

VERIFY.

2. Adjust manifold pressure to obtain input rate.

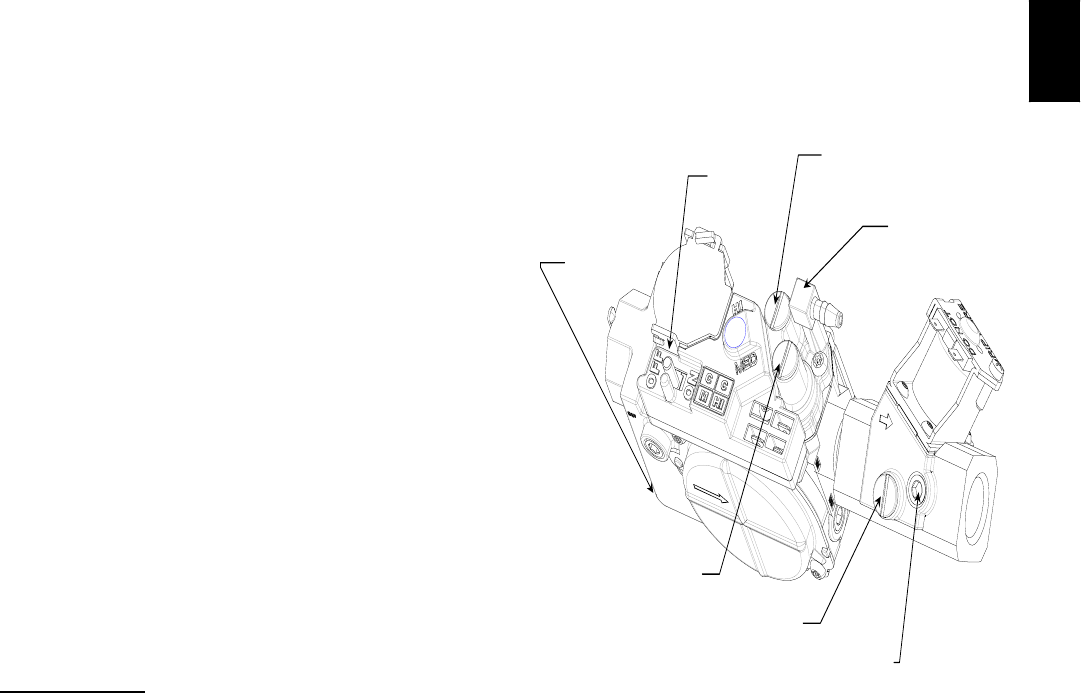

MEDIUM-HEAT

ADJUSTMENT

(UNDER CAP)

INLET

PRESSURE

TAP

ON/OFF

SWITCH

HIGH-HEAT

ADJUSTMENT

(UNDER CAP)

BURNER

ENCLOSURE

REFFERENCE

TAP

LOW-HEAT

ADJUSTMENT

(UNDER CAP)

MANIFOLD

PRESSURE

TAP

A07280

Fig. 60 -- Redundant Automatic Gas Valve

a. Remove burner enclosure front.

NOTE: Manifold pressure MUST always be measured with the

burner box cover REMOVED.

b. Remove regulator seal caps that conceal adjustment

screws for medium-- and high --heat gas valveregulators.

(See Fig. 60.)

c.MovesetupswitchSW4--2oncontrolcentertoON

position. (See Fig. 33.) This keeps furnace locked in

medium--heat operation.

d. Jumper R and W/W1 thermostat connections on control

to start furnace.

e. Turn medium --heat adjusting screw counterclockwise

(out) to decrease manifold pressure or clockwise (in) to

increase manifold pressure.

355CAV