32

FURNACE

PIPE DIAMETER

TRANSITION IN

VERTICAL SECTION

NOT IN

HORIZONTAL

SECTION

A93034

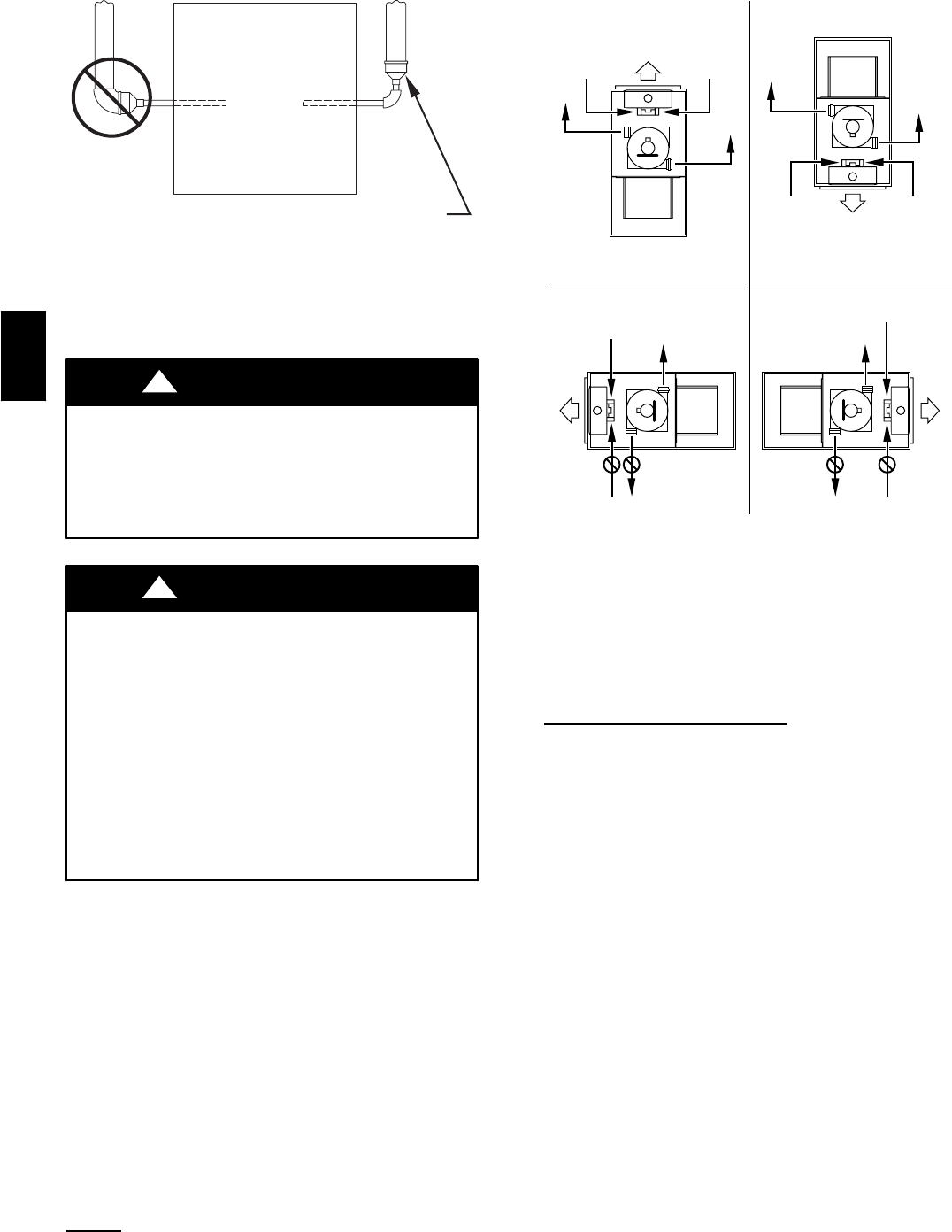

Fig. 38 -- Combustion Air and Vent Pipe Transition

Location and Elbow Configuration

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation.

When installing combustion air and vent system of short

pipe length, the smallest allowable pipe diameter must be

used.

CAUTION

!

UNIT CORROSION HAZARD

Failure to follow this caution may result in unit component

damage.

Excessive exposure to contaminated combustion air may

result in safety and performance related problems.

Combustion air must not be taken from inside structure

because that air is frequently contaminated by halogens,

which include fluorides, chlorides, bromides, and iodides.

These elements are found in aerosols, detergents, bleaches,

cleaning solvents, salts, air fresheners, adhesives, paint, and

other household products. Locate combustion--air inlet as

far as possible from swimming pool and swimming pool

pump house.

CAUTION

!

EXAMPLE: This 80,000 BTUH furnace located in Indianapolis,

elevation 650 ft above sea level, could be installed as a direct

vent/2--pipe system that requires 3 elbows and 17 ft of vent pipe,

along with 5 elbows and 16 ft of combustion--air pipe. Table 7

indicates this application would allow a 1--1/2--in. diameter vent

pipe, but require a 2--in. diameter combustion air pipe. According

to Table 7, 1--1/2--in. diameter pipe is good for 20 ft with 3

elbows, but only 10 ft with 5 elbows. Therefore, 2 --in. diameter

pipe must be used for both vent and combustion --air pipes since

the largest required diameter must always be used for both pipes.

If the same installation was made in Albuquerque, elevation 5250

ft above sea level, installation would require 2 -- in. diameter vent

pipe and combustion--air pipe. At 5001 to 6000--ft elevation,

1--1/2--in. pipe is not allowed with 5 elbows, but 2-- in. pipe is

good for 68 ft with 5 elbows are required.

COMBUSTION AIR PIPE

General

Furnace combustion--air connection must be attached as shown in

Fig. 39. Combustion --air intake housing plug may need to be

relocated in some applications.

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW DOWNFLOW

HORIZONTAL-LEFT DISCHARGE HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

VENT

VENT

VENT

NOTE: Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

A96187

Fig. 39 -- Combustion Air and Vent Pipe Connections

NOTE: All pipe joints must be cemented except a ttachment of

combustion --air pipe to inlet housing connection, since it may be

necessary to remove pipe for servicing.

NOTE: A 2--in. diameter pipe must be used within the furnace

casing. Make all pipe diameter transitions outside furnace casing.

Attachment of Combustion Air

Pipe

NOTE: Combustion air pipe system has the same diameter and

same length as the vent pipe as mentioned in section

“Combustion-- --Air and Vent Pipe Diameter .”

1. Determine location of combustion--air intake pipe

connection to combustion--air intake housing as shown in

Fig. 39 for application.

2. Verify combustion--air intake housing plug fitting is

installed in appropriate unused intake housing connection.

3. Install combustion--air pipe grommet (factory--supplied in

loose parts bag) into selected furnace casing combustionair

pipe hole.

4. Determine the number of combustion air disk halves to be

installed in the combustion air intake housing. Insert

perforated disk half or assembly (factory supplied in loose

parts bag) in intake housing where combustion--air intake

pipe will be connected.

5. Insert assembled combustion air inlet pipe into intake

housing as shown in Fig. 39.

NOTE: Do not cement combustion air intake pipe permanently

to combustion air intake housing since it may be necessary to

remove pipe for service of igniter or flame sensor.

6. Drill a 1/8 --in. hole in 2 --in, combustion air pipe using the

hole in intake housing as a guide.

7. Install a field--supplied No. 6 or No. 8 sheet metal screw

into combustion air pipe.

355CAV