12

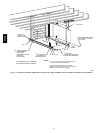

COMBUSTION – AIR

INTAKE

VENT

MANUAL

SHUTOFF

GAS VALVE

SEDIMENT

TRAP

CONDENSATE

TRAP

DRAIN

ACCESS OPENING

FOR TRAP

30″ MIN

WORK AREA

A 12-IN. MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

SHORT (5 TO 8 FT) VENT SYSTEMS

TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

5

3

⁄

4

″

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

A93031

Fig. 12 -- Attic Location and Working Platform for Direct

Vent (2 --Pipe) Application

PROPERTY DAMAGE

Failure to follow this caution may result in property

damage.

Local codes may require a drain pan under entire furnace

and condensate trap when a condensing furnace is used in

an attic application or over a finished ceiling.

CAUTION

!

NOTE: In Canada, installations shall be in accordance with

current NSCNGPIC and/or local codes.

Condensate Trap

Location

The condensate trap must be removed from the factory--installed

blower shelf location and relocated in selected application

location as shown in Fig. 2 or 11.

To relocate condensate trap from the blower shelf to desired

location, perform the following:

1. Remove three tubes connected to condensate trap.

2. Remove trap from blower shelf by gently pushing tabs

inward and rotaing trap.

3. Remove casing hole filler cap from casing hole. (See Fig.

2or11.)

4. Install casing hole filler cap (factory--supplied in loose

parts bag) into blower shelf hole where trap was removed.

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal

injury or death.

Casing hole filler cap must be installed in blower shelf hole

when condensate trap is relocated to prevent combustion

products being drawn in from appliances in the equipment

room.

!

WARNING

5. Install condensate trap into left--hand side casing hole by

inserting tube connection stubs through casing hole an

rotating until tabls snap into locking position.

6. Fill unused condensate trap casing holes with plastic filler

caps (factory--supplied in loose parts bag).

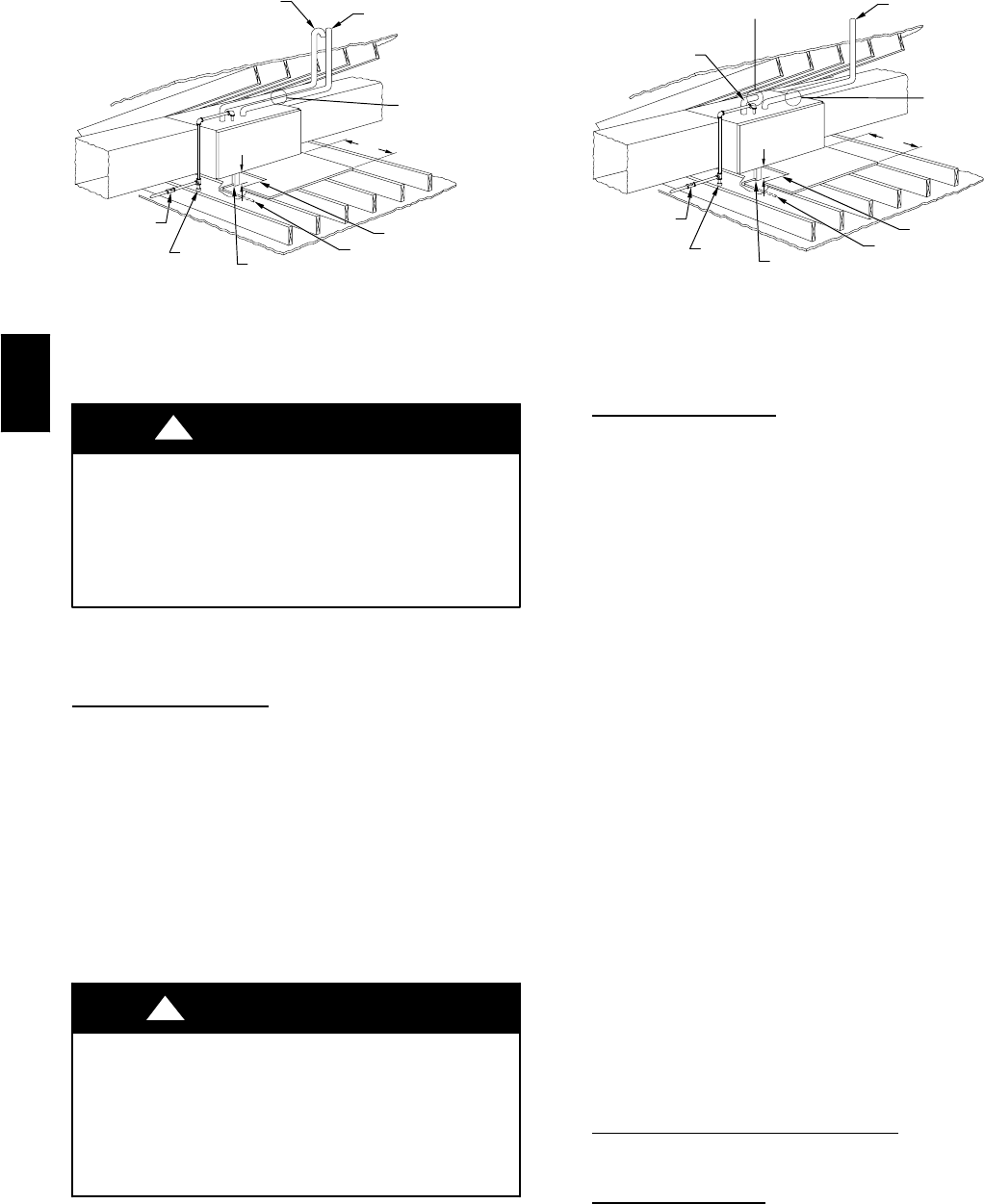

VENT

MANUAL

SHUTOFF

GAS VALVE

SEDIMENT

TRAP

CONDENSATE

TRAP

DRAIN

ACCESS OPENING

FOR TRAP

30-IN. MIN

WORK AREA

A 12-IN. MIN HORIZONTAL PIPE

SECTION IS RECOMMENDED WITH

SHORT (5 TO 8 FT) VENT SYSTEMS

TO REDUCE EXCESSIVE

CONDENSATE DROPLETS FROM

EXITING THE VENT PIPE.

A 3-IN. MINIMUM CLEARANCE

TO COMBUSTION-AIR INTAKE

IS REQUIRED.

5

3

⁄

4

″

NOTE: LOCAL CODES MAY REQUIRE A DRAIN PAN UNDER THE

FURNACE AND CONDENSATE TRAP WHEN A CONDENSING

FURNACE IS INSTALLED ABOVE FINISHED CEILINGS.

COMBUSTION–AIR

INTAKE

A96184

Fig. 13 -- Attic Location and Working Platform for

Ventilated Combustion Air Applications

Condensate Trap T

ubing

NOTE: See Fig. 11 or tube routing label on main furnace door

to check for proper connections.

1. Collector Box DrainTube

a. Install drain tube coupling (factory --supplied in loose

partsbag)intocollectorboxdraintube(bluelabel)which

was previously connected to condensate trap.

b. Connect lar ge diameter drain tube and clamp

(factory--supplied in loose parts bag) to drain tube

coupling, extending collecor box drain tube.

c. Route extended tube (blue label) to condensate trap and

cut to appropriate length.

d. Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

(a.)Remove and discard LOWER (molded) inducer

housing drain tube which was previously

connected to condensate trap.

(b.)Use inducer housing drain extension tube (violet

label and factory--supplied in loose parts bag) to

connect LOWER inducer housing drain

connection to condensate trap.

(c.)Determine appropriate length, cut and connect

tube.

(d.)Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

a. Extend collector box tube (green label) which was

previously connected to condensate trap by splicing to

smalldiametertube(factory--suppledin loosepartsbag).

b. Route extended collector box pressur tube to relief port

connectio on condensate trap.

c. Determine appropriate length, cut, and connect tube.

d. Clamp tube to prevent any condensate leakage.

Condensate Trap Field Drain

Attachment

Refer to Condensate Drain section for recommendations and

procedures.

Pressure Switch T

ubing

The LOWER collector box pressure tube (pink label) is factory

connected to the High Pressure Switch for use when furnace is

installed in UPFLOW applications. This tube MUST be

disconnected, extended rerouted, and then reconnected to the

pressure switch in HORIZONTAL LEFT applications for 060

and 080 heating input furnaces.

NOTE: See Fig. 11 or tube routing label on main furnace door

to check for proper connections.

Modify tube as described below.

355CAV