27

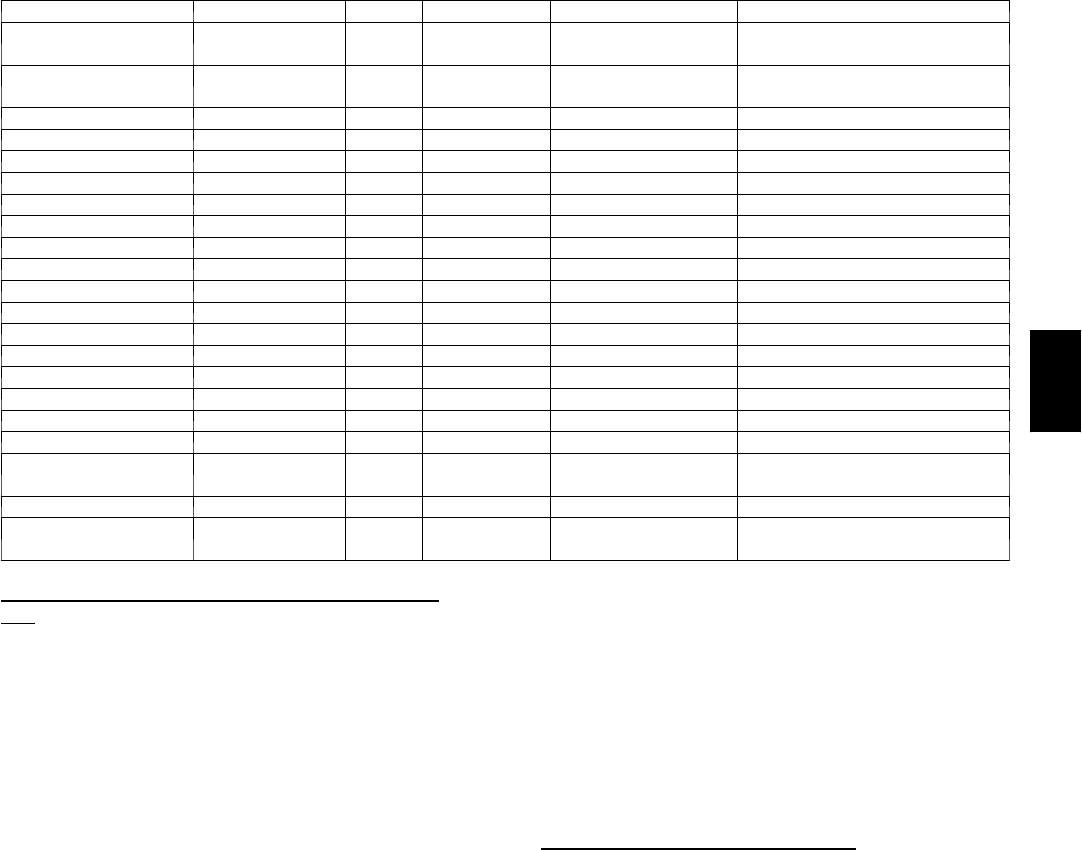

Table 5 – Approved Combustion--Air and Vent Pipe, Fitting and Cement Materials

ASTM

SPECIFICATION MATERIAL PIPE FITTINGS

SOLVENT

CEMENT

DESCRIPTION

(MARKED ON

MATERIAL)

AND PRIMERS

D1527 ABS Pipe — — Schedule40

D1785 PVC Pipe — — Schedule40

D2235 For ABS — — Solvent For ABS

Cement

D2241 PVC Pipe — — SDR21 & SDR26

D2466 PVC — Fittings — Schedule40

D2468 ABS — Fittings — Schedule40

D2564 For PVC — — Solvent For PVC

Cement

D2661 ABS Pipe Fittings — DWV at Schedule40 IPS sizes

D2665 PVC Pipe Fittings — DWV

F438 CPVC — Fittings — Schedule40

F441 CPVC Pipe — — Schedule40

F442 CPVC Pipe — — SDR

F493 For CPVC — — Solvent For CPVC

Cement

F628 ABS Pipe — —

Cellular Core DWV at Schedule40

IPS sizes

F656 ForPVC — — Primer For PVC

F891 PVC Pipe — —

Cellular Core Schedule40 &

DWV

Installation Guidelines for Combustion Air Pipe and Vent

Pipe

It is recommended that all pipes be cut, prepared, and

preassembled before permanently cementing any joint.

1. Attach combustion air pipe and vent pipe per instructions

in sections “Combustion Air Pipe” and “Vent Pipe.”

2. Working from furnace to outside, cut pipe to required

length(s).

3. Deburr inside and outside of pipe.

4. Chamfer outside edge of pipe for better distribution of

primer and cement.

5. Clean and dry all surfaces to be joined.

6. Check dry fit of pipe and mark insertion depth on pipe.

7. After pipes have been cut and preassembled, apply

generous layer of cement primer to pipe fitting socket and

end of pipe to insertion mark. Quickly apply approved

cement to end of pipe and fitting socket (over primer).

Apply cement in a light, uniform coat on inside of socket

to prevent buildup of excess cement. Apply second coat.

8. While cement is still wet, twist pipe into socket with 1/4

turn. Be sure pipe is fully inserted into fitting socket.

9. Wipe excess cement from joint. A continuous bead of

cement will be visible around perimeter of a properly

made joint.

10. Handle pipe joints carefully until cement sets.

11. Horizontal portions of the venting system shall be

supported to prevent sagging. Support combustion air

piping and vent piping a minimum of every 5 ft (1.5 m)(3

ft (.91 m) for SDR--21 or --26 PVC) using perforated

metal hanging strap.

12. Slope combustion air piping and vent piping downward

towards furnace a minimum of 1/4 --in. per linear ft with no

sags between hangers.

13. Horizontal portions of the venting system shall be installed

so as to prevent the accumulation of condensate.

14. Use appropriate methods to seal openings where

combustion air pipe and vent pipe pass through roof or

sidewall.

Combustion--Air and Vent Pipe

Diameter

Determine combustion--air and vent pipe diameter.

1. Using Table 7, individually determine the diameter of the

combustion--air and vent pipe allowed. If different, pick

the larger of these two diameters and use this diameter for

both combustion--air and vent pipes.

2. When installing vent systems of short pipe length, use the

smallest allowable pipe diameter . Do not use pipe size

greater than required or incomplete combustion, flame

disturbance, or flame sense lockout may occur.

NOTE: Do not count elbows or pipe sections in terminations or

within furnace.

NOTE: A 2--in. diameter pipe must be used within furnace

casing. Make all pipe diameter transitions outside furnace casing.

355CAV