43

2. Locate heat tape between sides of condensate trap back.

(See Fig. 46.)

3. Use wire ties to secure heat tape in place. Wire ties can be

positioned in notches of condensate trap sides. (See Fig.

46.)

4. W rap field drain pipe with remaining heat tape,

approximately 1 wrap per ft.

5. When using field--supplied heat tape, follow heat tape

manufacturer’s instructions for all other installation

guidelines.

START--UP, ADJUSTMENT AND SAFETY

CHECK

Step 1 — General

1. Furnace must have a 115--v power supply properly

connected and grounded.

NOTE: Proper polarity must be maintained for 115--v wiring. If

polarity is incorrect, c ontrol status indicator light flashes r apidly

and furnace does not operate.

2. Thermostat wire connections at terminals R, W/W1, G,

and Y/Y2 must be made at 24--v terminal block on furnace

control.

3. Natural gas service pressure must not exceed 0.5 psig (14--

in. wc), but must be no less than 0.16 psig (4.5--in. wc).

4. Blower access panel must be in place to complete 115--v

electrical circuit to furnace.

UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation or performance satisfaction.

These furnaces are equipped with a manual reset limit

switch in burner box. This switch opens and shuts off

power to the gas valve if an overheat condition (flame

rollout) occurs in burner enclosure. Correct inadequate

combustion --air supply or improper venting condition

before resetting switch. DO NOT jumper this switch.

CAUTION

!

Before operating furnace, check flame rollout manual reset switch

for continuity. If necessary, press button to reset switch.

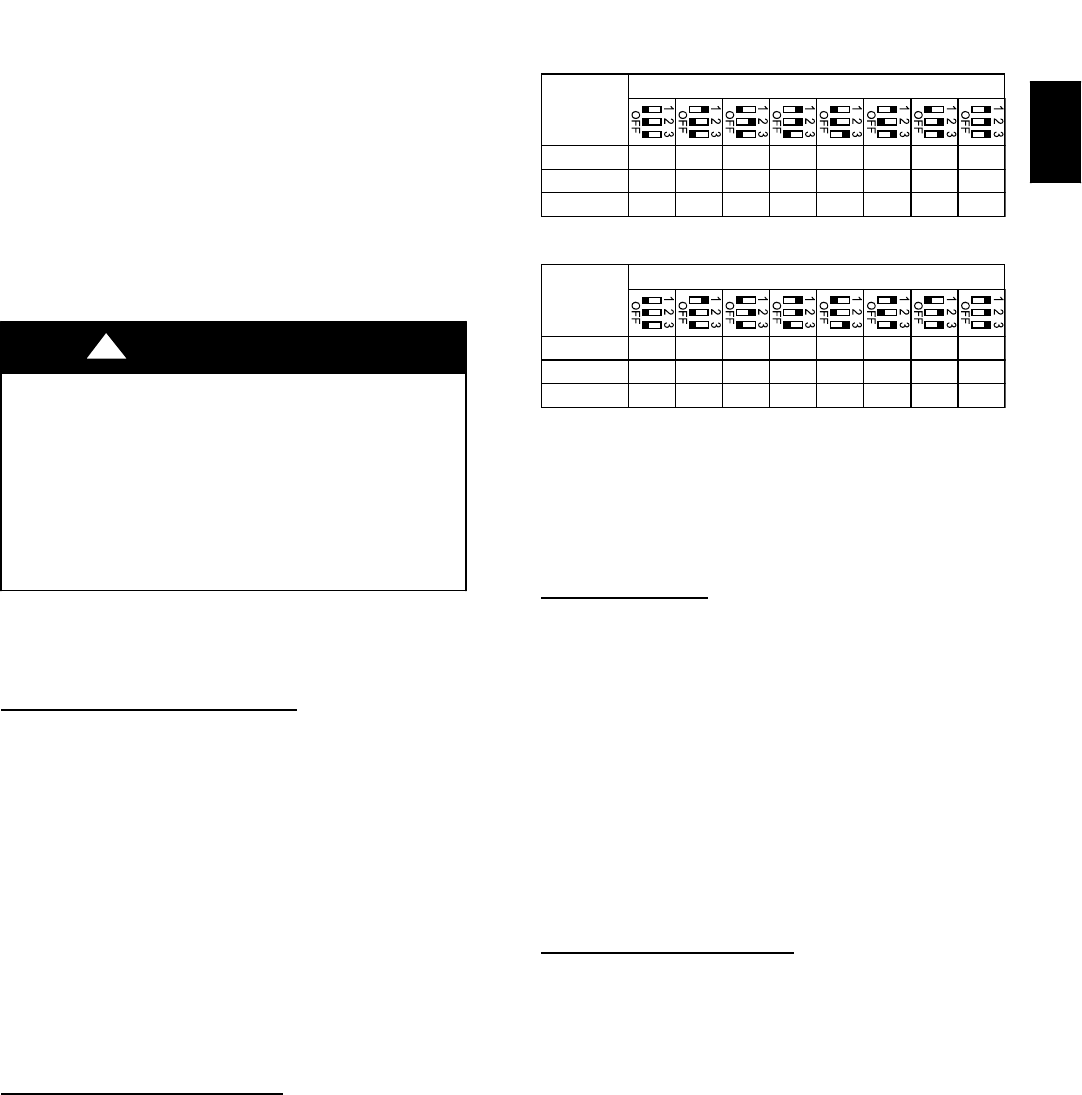

Step 2 — Select Setup Switch Positions

Air Conditioning (A/C) Setup Switches

The air conditioning setup switches are used to match furnace

airflow to cooling unit used.

To set the desired cooling airflow:

1. Remove main furnace door and blower access panel.

2. Locate A/C setup switches on furnace control. (See Fig.

33.)

3. Determine air conditioning tonnage used.

4. Use Fig. 47 or wiring schematic to determine proper setup

position of A/C switches. (See Fig. 48 and Fig. 49.)

NOTE: Excessive airflow caused by improper A/C switch setup

may cause condensate blowoff in cooling mode.

5. Replace main furnace door and blower access panel.

NOTE: EAC--1 terminal is energized whenever blower operates.

HUM terminal is only energized when blower is energized in

heating.

Continuous Fan (CF) S etup

Switches

The CF setup switches are used to select desired airflow when

thermostat is in continuous fan mode or to select low--cooling

airflow for two--speed cooling units. This setup feature allows

continuous fan airflow or low--cooling airflow to be adjusted. To

set desired continuous fan airflow or low--cooling airflow:

1. Remove main furnace door and blower access panel.

2. Locate CF setup switches on furnace control. (See Fig.

33.)

3. Determine desired continuous fan airflow or low--cooling

airflow.

4. Use Fig. 47 or wiring schematic to determine proper setup

position of CF switches. (See Fig. 48 and Fig. 49.)

5. Replace main furnace door and blower access panel.

525

2

700

2

700

875

1050

875

700 875

2

1050

1050

1

1225

1225

1225

1400

1400

1225

1750

1

1750

1

1225

1750

2100

DEF.

DEF.

DEF.

5T080, 100

120

BASED ON 350 CFM/TON (SETUP SWITCH SW1-5 OFF)

SETUP SWITCH SW3 POSITIONS

MODEL

SIZE

600

2

800

2

800

1000

1200

1000

800 1000

2

1200

1200

1

1400

1400

1400

1600

1600

1400

2000

1

2000

1

1400

2000

2100

DEF.

DEF.

DEF.

060, 3.5T080

5T080, 100

120

BASED ON 400 CFM/TON (SETUP SWITCH SW1-5 ON)

1. DEFAULT A/C AIRFLOW WHEN A/C SWITCHES ARE IN OFF POSITION

2. DEFAULT CONT. FAN AIRFLOW WHEN CF SWITCHES ARE IN OFF POSITION

3. SWITCH POSITIONS ARE ALSO SHOWN ON FURNACE WIRING DIAGRAM

SETUP SWITCH SW3 POSITIONS

MODEL

SIZE

AIR CONDITIONING (A/C) OR CONTINUOUS-FAN (CF)

AIRFLOW SELECTION CHART

060, 3.5T080

A07424

Fig. 47 -- A/C or CF Airflow Selection Chart Based on 350

and 400 CFM/Ton

Setup Switches

(SW1)

The furnace control has 8 setup switches that may be set to meet

the application requirements. To set these setup switches for the

appropriate requirement:

1. Remove main furnace door and blower access panel.

2. Locate setup switches on furnace control. (See Fig. 33.)

3. See Table 9 for setup switch description. (See Fig. 48 and

Fig. 49.)

4. Replace main furnace door and blower access panel.

NOTE: If a bypass humidifier is used, setup switch SW1--3

(Low Heat Rise Adjust) should be in ON position. This

compensates f or the increased temperature in return air resulting

from bypass.

NOTE: If modulating dampers are used, blower motor

automatically compensates for modulating dampers.

Additional Setup Switches

(SW4)

The furnace control has 3 additional setup switches labeled SW4.

(See Fig. 33.) Setup switch SW4--2 can be used to lock the

furnace into medium heat. When setup switch SW4 --2 is ON the

furnace will remain at medium heat until W/W1 is de--energized

to end a heating cycle or when both W/W1 and W2 are energized.

When both W/W1 and W2 are energized the furnace will run at

high heat. The other 2 setup switches are currently not used for

anything. When setup switch SW4--2 is ON it will over ride setup

switch SW1--2 if it is ON. To activate setup switch SW4--2:

1. Remove main furnace door and blower access panel.

355CAV