61

4

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

LD06358

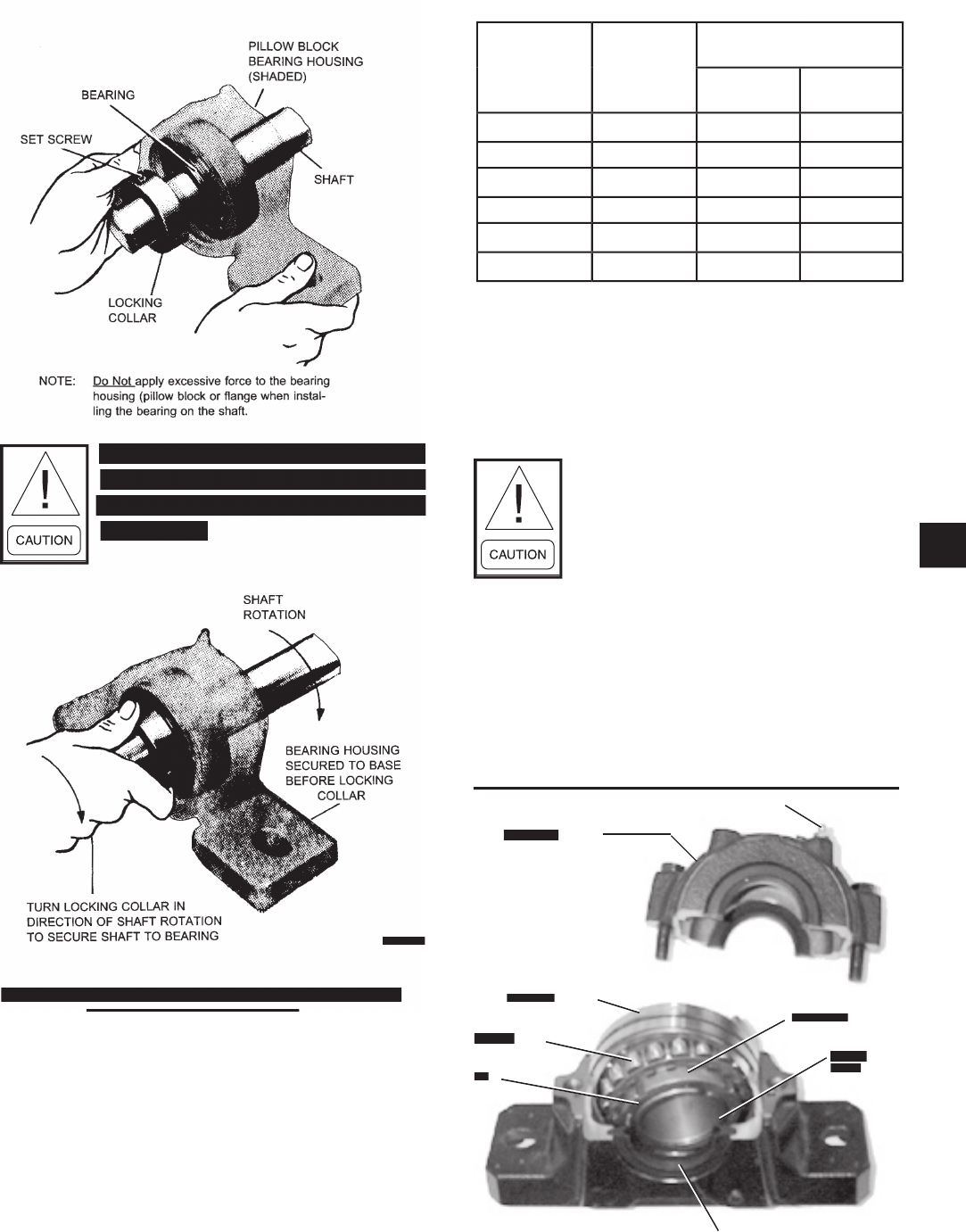

FIG. 4-7 – ECCENTRIC CAM LOCKING COL LAR

BEARING INSTALLATION

BEARING INSTALLATION

Do not apply excessive force to the

bear ing hous ing (pillow block or

bear ing hous ing (pillow block or

fl ange) when installing the bearing

fl ange) when installing the bearing

on the shaft.

Torquing of Set-screws

1. Torque screw “A” to 1/2 rec om mend ed torque.

2. Torque screw “B” to full min. recommended

val ue.

3. Torque screw “A” to full rec om mend ed value.

After proper installation of the

bearing(s), run the unit for 10 to 15

minutes. Shut the unit down and lock

it out. Check for proper en gage ment

of locking col lar and tight ness of set

screw(s).

When replacing split bearings, refer to manufacturer’s

instruction provided with the bearing.

It is extremely

important to ensure that proper radial clearances are

observed between the roller bearings and outer face.

Failure to make proper adjustments will cause pre ma ture

failure of the bearing.

TABLE 4-2 – SET SCREW TORQUE

FIG. 4-8 – SPLIT BEARING

00536vip

bearing cap

grease fi tting

outer race

bearings

nut

seal

lock washer

tapered

sleeve

SET

SCREW

DIA.

HEX. SIZE

ACROSS

FLATS

LBS.

MIN. RECOMMENDED

TORQUE

INCH

LBS.

FOOT

LBS.

1/4 1/8

66 - 85

5.

5 - 7

.2

5/16

5/32

126 - 164

10.5 - 13.7

3/8 3/16

228 - 296

19.0 - 24.7

7/16

7/32

348 - 452

29.0 - 37.7

1/2 1/4

504 - 655

42.0 - 54.6

5/8 5/16

1104 - 1435

92.0 - 119.6