156

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

Service

Furnace Status Input

The Unit Controller monitors the operation of the

Staged and Modulating Gas Heat sections and displays

the status through the STATUS screen of the User

Interface. The operation of each of the gas heat sections

is monitored by a multiplexer installed in the gas heat

section. When a gas heat section is energized, it sends a

24-volt signal to the multiplexer. The multiplexer takes

the fi ve “ON”/”OFF” inputs and converts them into a

0 to 5 volt DC signal that is sent to the Unit Controller.

The Unit Controller then decodes this analog input and

displays the furnace section status. Tables 8-9 and 8-10

show the relationship between the DC voltage and the

furnace operation status.

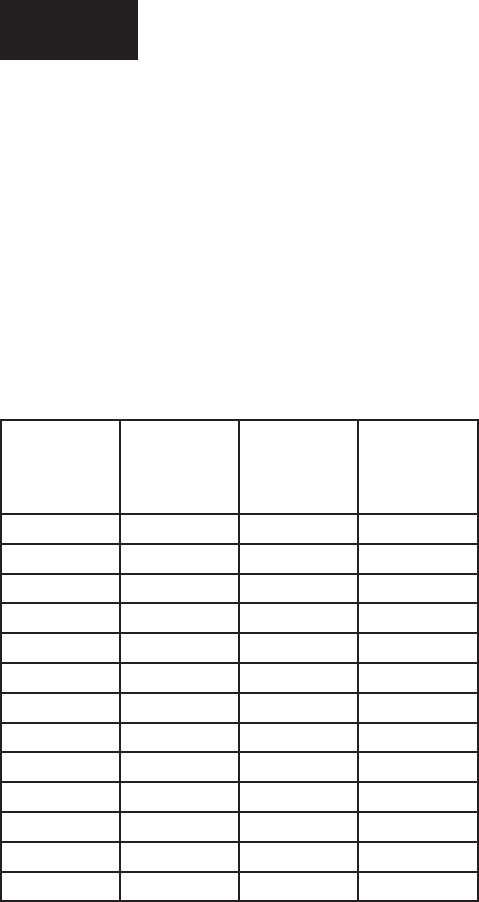

PPM CO2 OUTPUT

VOLTAGE

VDC

PPM CO2 OUTPUT

VOLTAGE

VDC

80 0.20 1120 2.80

160 0.40 1200 3.00

240 0.60 1280 3.20

320 0.80 1360 3.40

400 1.00 1440 3.60

480 1.20 1520 3.80

560 1.40 1600 4.00

640 1.60 1680 4.20

720 1.80 1760 4.40

800 2.00 1840 4.60

880 2.20 1920 4.80

960 2.40 2000 5.00

1040 2.60

TABLE 8-7 – CO2 SENSOR OUTPUT

CO

2

Sensor

Two CO

2

sensors are used in conjunction with the

“DEMAND VENTILATION” option. In “DEMAND

VENTILATION” the Unit Control monitors the CO

2

level

of the outdoor air and the CO

2

level in the conditioned

space and varies the amount of ventilation air based on

the relationship between these two values. Table 8-7

gives the volts DC output for a given CO

2

level.