60

Maintenance

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

Prior to installing the bearing on the shaft, it should

be worked around in the housing to make sure that

self-alignment will be obtained where the bear ing is

in stalled. After the shaft journal has been in spect ed for

clean li ness, metal chips or burrs, the bearing is slipped,

not forced, onto the shaft. Forc ing the bear ing onto the

shaft by the use of fl ange, pillow block, or outer ring

will dam age the bearing in ter nal ly. Force ap plied in this

way transmits the load to the inner race through the balls

in the bear ing. Since the bearings are not de signed for

axial load ing, the sides of the races in which the balls

turn can be damaged. If the bear ing cannot be made to

slip onto the shaft by press ing on the inner ring of the

bear ing, check the shaft for burrs. In stall the bearing so

the part of the inner race, which receives the locking

collar or contains setscrews, is toward the outside of

the unit.

If the grease fi tting must be changed on bearings that

utilize a locking pin under the fi tting, it is important

to properly replace it. If an adapter or grease fi tting of

im prop er size and length is used, the locking pin may

be either too tight or loose and can affect the alignment

and re-lubrication of the bearing.

Bearing Lock Devices

Various types of locking devices are used to secure

bearing(s) to the fan shaft. Refer to the instructions

packed with bearings for special information. Figure

4-5 is a typical bearing with a setscrew-type locking

de vice. The various locking devices can be clas si fi ed

un der ba sic types: ec cen tric locking type, concentric

lock ing type, and Skwezloc type.

Eccentric Type

An eccentric self-locking collar is turned and driven

with a punch in the direction of shaft rotation to lock

the bear ing inner ring to the shaft. See Figure 4-7.

When the eccentric collar is engaged to the cam on the

bearing inner ring and turned in di rec tion of ro ta tion, it

grips the shaft with a positive binding action. The collar

is then locked in place with the setscrew provided in

the collar.

The self-locking collar is placed on the shaft with its

cam adjacent to the cam on the end of the bear ing’s wide

inner ring. In this position, with collar and bear ing cams

dis en gaged, the col lar’s bore is con cen tric with that of

the bearing’s inner ring. The wide inner ring is loose

on the shaft. By turning the collar in the direction of

normal shaft ro ta tion, the eccentric re cessed cam will

drop over and engage with the cor re spond ing cam on

the bearing inner, causing it to grip the shaft tightly with

a pos i tive binding action. See Fig ure 4-6 & 4-7. Make

sure the two cams engage smoothly and the locking

collar is down fl at against the shoul der of the inner ring.

The wide inner ring is now locked to the shaft. Using

a punch or similar tool in the drilled hole of the collar,

tap the tool lightly to lock the collar in the di rec tion of

nor mal shaft rotation.

As a fi nal step, the setscrew is tightened. Torque per

Table 4-2. It exerts a wedging action to hold the collar

always in the engaged po si tion, even under shock and

reversing loads.

To disassemble, loosen the setscrew and tap the collar

in the direction opposite shaft ro ta tion.

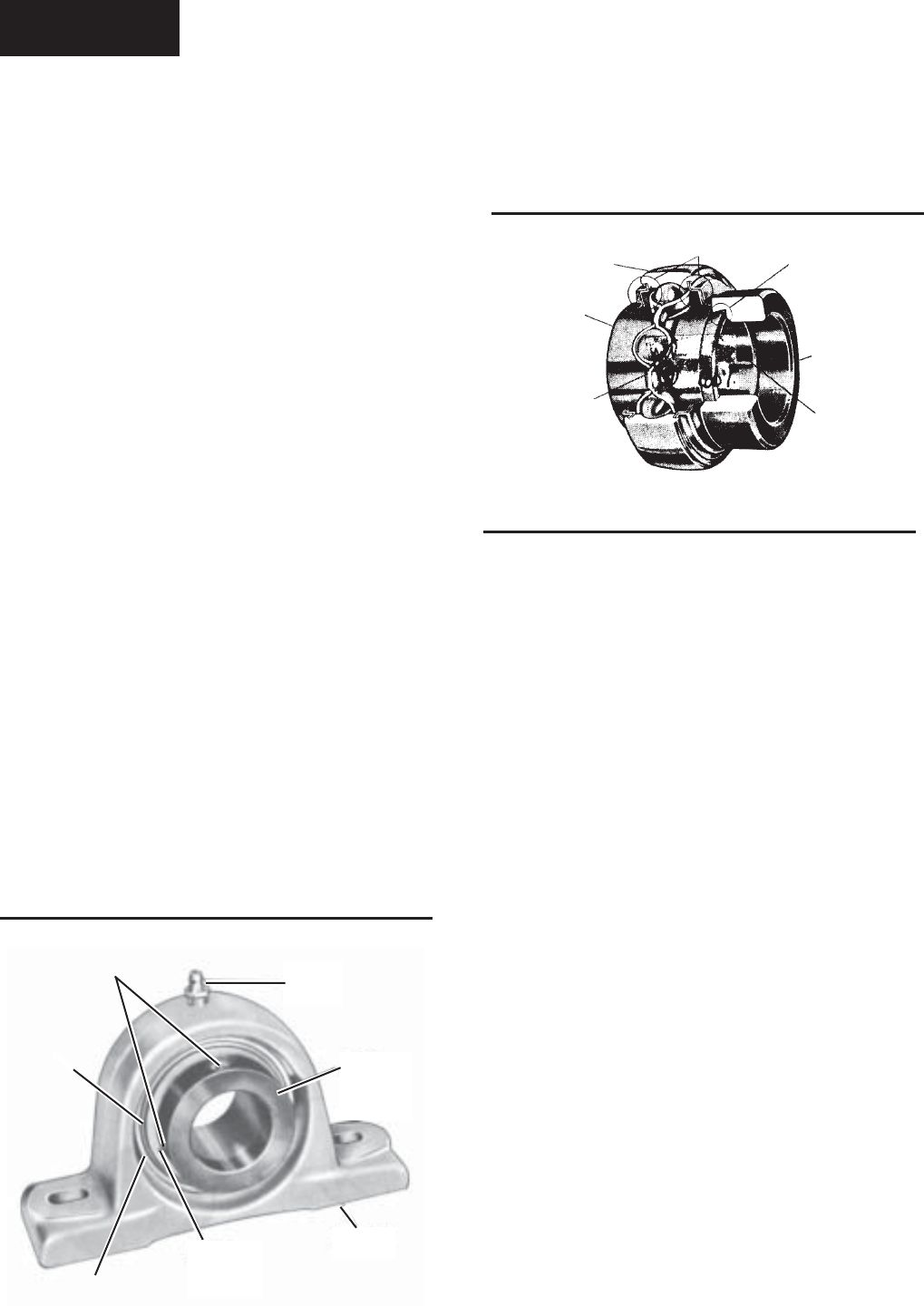

FIG. 4-5 – BEARING WITH SETSCREW TYPE

LOCKING DEVICE

LD06357

00418VIP

Seal

Set

Screws

Lube

Fitting

Lock

Ring

Pillow

Block

Inner

Race

Outer

Race

FIG. 4-6 – BEARING WITH ECCENTRIC CAM

RECESSEDCAMORSELF-

LOCKINGCOLLAR

SELFLOCKINGCOLLAR

CAMORINNERRING

BALLSANDRACEWAY

INNERRING

OUTERRING

SEALASSEMBLY