44

JOHNSON CONTROLS

FORM 100.50-NOM6 (1207)

Installation

DUCT SYSTEM

Duct Connection Guidelines

All intake and discharge air duct connection to the

unit may be made directly to the unit. These air duct

con nec tions should be on fl exible material and should

be installed so they are suffi ciently loose. Duct runs

and transitions must be made carefully to hold friction

loss to a min i mum. Avoid short turns, and duct elbows

should con tain splitters or turning vanes.

Duct work connected to the fan discharge should run in a

straight line for at least two equiv a lent outlet di am e ters.

Never dead head the dis charge into the fl at sur face of

a plenum.

Refer to Table 2-17 and 2-18 for available supply and

return duct connection confi guration.

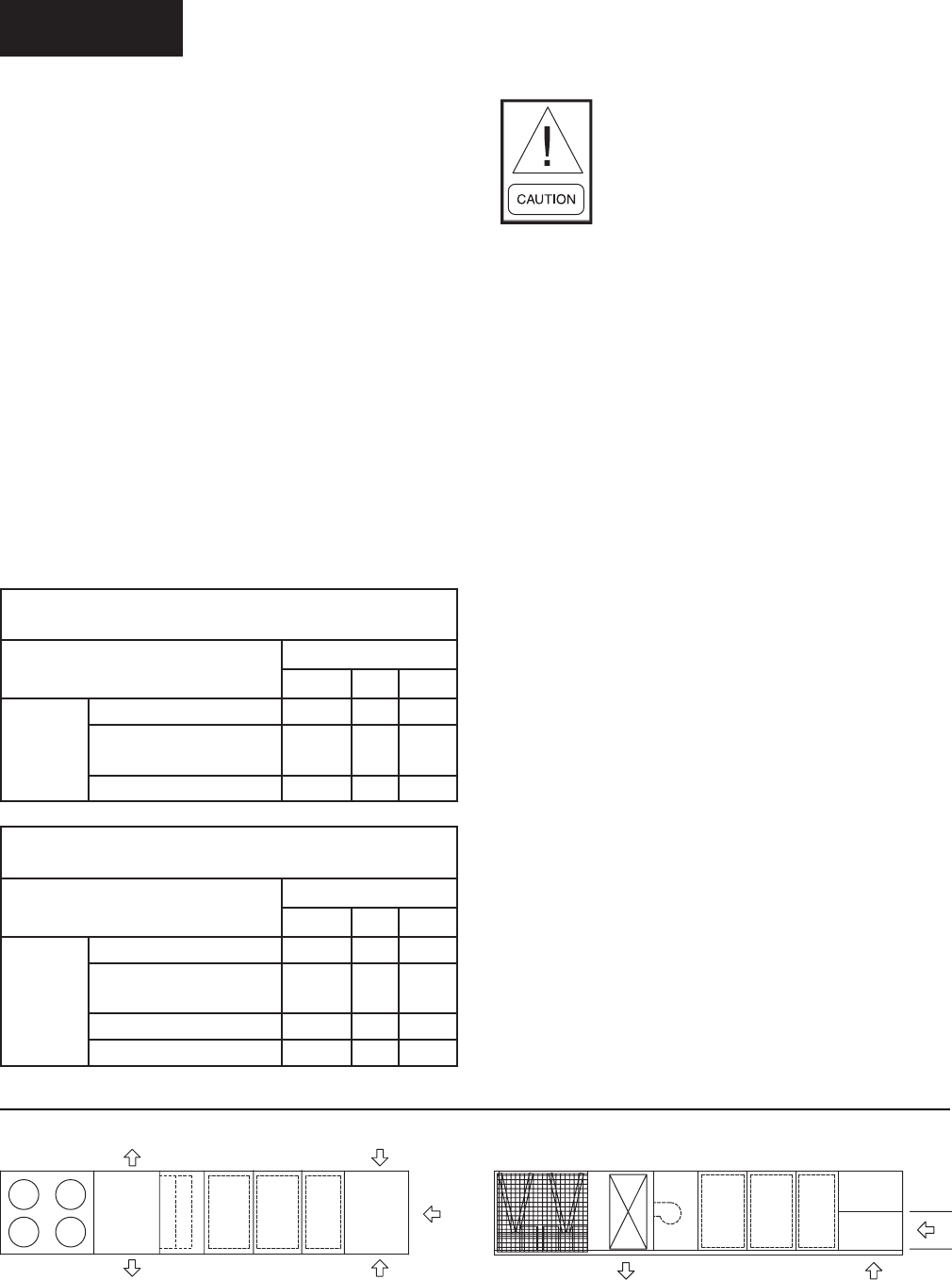

TABLE 2-17 – SUPPLY AIR DUCT CONNECTION

CONFIGURATIONS

UNIT CONFIGURATION

SUPPLY AIR

BOTTOM LEFT RIGHT

50-61 TONS

COOLING ONLY

√

√√

COOL/GAS HEAT 375-750

MBH

√√N/A

COOL/GAS HEAT 1125 MBH √ N/A N/A

TABLE 2-18 – RETURN AIR DUCT CONNECTION

CONFIGURATIONS

UNIT CONFIGURATION

SUPPLY AIR

BOTTOM LEFT RIGHT

50-61 TONS

NO EXHAUST √ √ √

BAROMETRIC RELIEF

DAMPER

√√N/A

POWERED EXHAUST FAN √ √ N/A

RETURN FAN √ N/A N/A

Installation of elbows, discharge

damp er and oth er abrupt fl ow area

changes installed di rect ly at the fan

outlet will cause system losses. These

losses must be taken into account

dur ing the de sign phase and must be

add ed to any fi eld mea sure ments.

SOUND AND VIBRATION TRANS MIS SION

All roof mounted air handling units generate some

sound and vibration, which may or may not require

some special treatment of the air con di tioned space. The

noise gen er at ed by the air handling unit is dependent

on the speed of the fan, the amount of air the fan is

moving, the fan type and the static effi ciency of the fan.

In ap pli ca tions where sound and vibration transmissions

may be ob jec tion able, good acoustical engineering

prac tic es must be incorporated in the system design.

The eco

2

unit is designed for lower sound levels than

competitive units by using fl exible fan connections,

fan spring isolators, double-wall construction, multiple

fan options, and lower speed and horsepower fans. For

VAV applications, VFDs are used instead of inlet guide

vanes. Additional sound attenuation can be obtained

using compressor sound blankets and fi eld-supplied

sound attenuators when necessary.

Even with these equipment design features, the

acoustical characteristics of the entire installation must

never be overlooked. Additional steps for the acoustical

characteristics of a rooftop installation should be

addressed during the design phase of a project to avoid

costly alterations after the installation of the equipment.

During the design phase of a project, the designing

engineer should consider, at a minimum, the impact of

the equipment location, rooftop installation, building

structure, and duct work.

BOTTOM

FRONT

LEFT

RIGHT

FRONT

Discharge Return

LD08045

NOTE:

This diagram is provided as a visual reference of the eco

2

discharge & return air openings & locations for all sizes. Please refer to Fig 2-4 for exact

size & location of panels and openings.