Part number 550-141-850/069960

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

Gas piping

1. Sniff near floor and around boiler area for any indication of a gas leak.

2.

Test gas piping using bubble test, per Section V of this manual, if there is any indication

of a leak.

Cold fill and operating pressures

1. While the system is cold, note the pressure reading on the boiler pressure/temperaure

gauge. Verify that cold fill pressure is correct.

2. Watch the pressure as the boiler and system heat up to ensure pressure rise is normal. Too

high a rise would indicate a waterlogged or undersized expansion tank.

Temperature mixing system

1. Carefully check the temperature of the system return piping as it passes through the

boiler jacket and on the return pipe inside the boiler jacket just before it enters the

boiler sections. You may do this with a surface pyrometer or by lightly touching the piping

with your fingers.

To avoid potential of severe burn — Do not rest hands on or grasp

pipes

. Use a light touch only. Return piping may heat up quickly.

2. The temperature of the water entering the boiler sections should quickly heat up to about

130 °F, being considerably hotter than the return water from the system.

3. This is accomplished with the two internal boiler circulators. The Bypass circulator

(page 2, item 7) takes hot water from the boiler supply outlet and blends it with return water.

The System circulator (page 2, item 6) slows down to aid in raising the return temperature

entering the sections.

4. If the temperature mixing system does not work correctly, check the two circulators to be

sure they are flowing water. If the circulators are operating normally but the temperature

mixing system does not maintain water at the enterance to the boiler sections at 130 °F, you

may need to replace the boiler control module or water temperature sensor (page 2, item 8).

Annual start-up —

check/test

Service & maint. — annual start-up (cont.)Xc

Air vents and air elimination

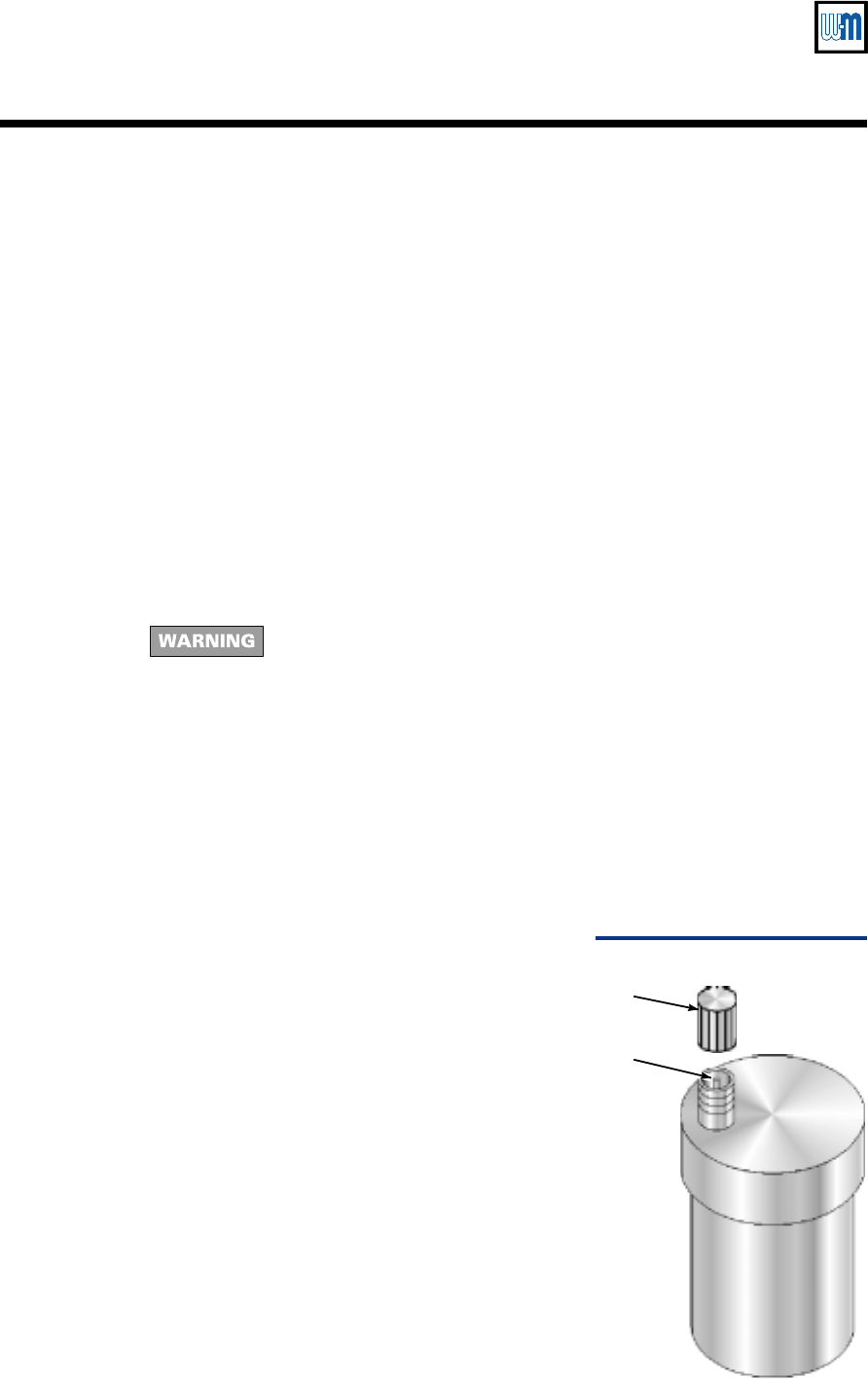

1. Inspect automatic air vents (if used). Also inspect air

separators to ensure they are operational.

2. The cap must be unscrewed one turn to allow air to

escape.

3. See Figure 28. If the air vent is leaking, remove cap A

and briefly push valve B and then release to clean the

valve seat.

4. Replace cap A by twisting all the way onto valve B

and then unscrewing one turn.

85036

A

B

Limit controls and cutoffs

1. Inspect and test the boiler limit control. Verify

operation by turning control set point below boiler

temperature. Boiler should cycle off. Return dial to

original setting.

2. Inspect and test additional limit controls or low water

cutoffs installed on system.

Figure 28 Automatic air vent