Part number 550-141-850/069930

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

Water piping — all systemsIIId

Zoning with

circulators

Zoning with

zone valves

The GV internal system circulator cannot be removed

from the boiler for use as one of the zone circulators. It

must remain as shipped from the factory to allow proper

flow control inside the boiler. You will need a circulator

for each zone.

Size the common (primary) pipe for the combined flow

of all circulators, or with a pipe cross-sectional area at

least equal to the total areas of all zone supply pipes. You

may also use the alternative sizing chart at right, based

on maximum flow of 10 gmp per circulator.

Install and wire a separate relay for each zone circulator.

Each zone in the piping diagrams in this section is shown with an isolation valve on each side.

Substitute a memory-stop valve for one of these in each zone in order to use the memory-stop

valve for balancing flow as well as isolation.

Provide a separate 24-volt transformer to power the zone valves. Size the transformer to handle

the total rated load of all connected zone valves.

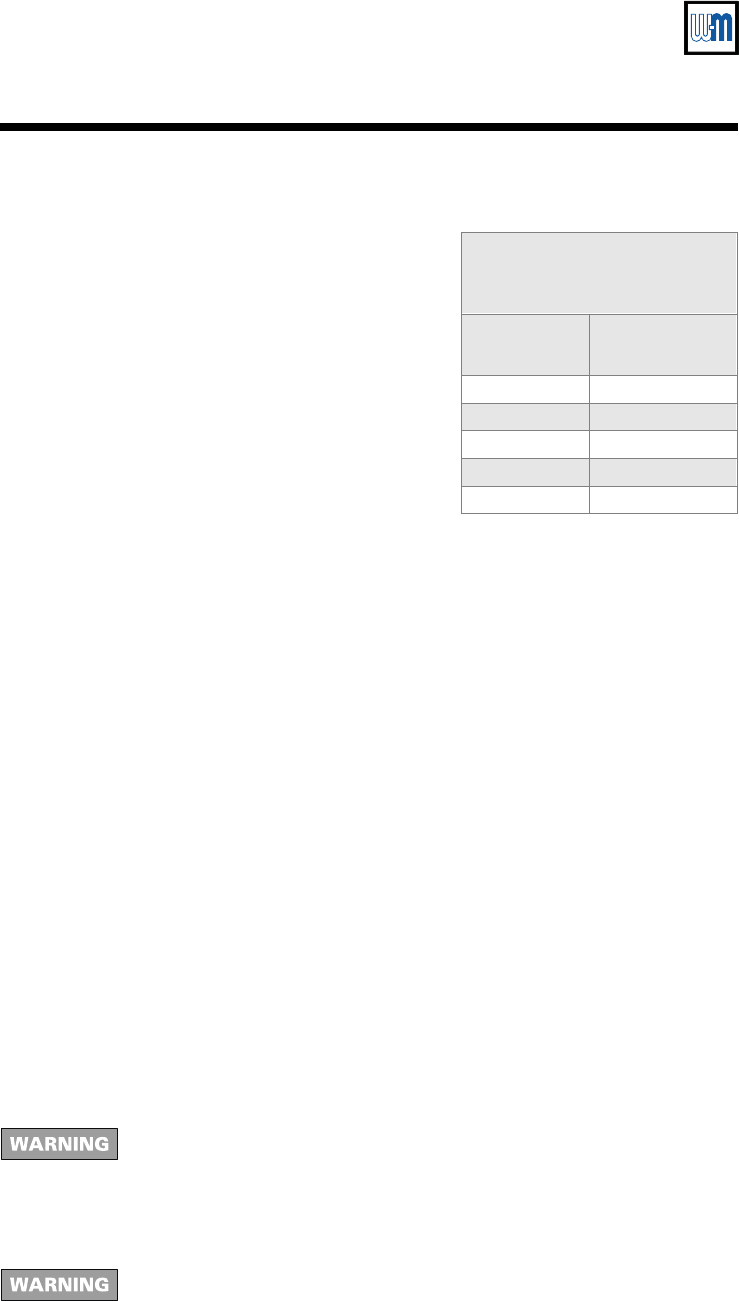

Alternate primary

manifold sizing

(max 10 gpm per circulator)

Number of

circulators

Suggested

pipe size

1 1"

2 – 3 1½"

4 – 5 2"

6 – 8 2½"

9 – 12 3"

Additional

components

If installation is to comply with ASME or Canadian requirements, an additional high

temperature limit

is needed.

• Purchase and install in system supply piping between boiler and isolation valve.

• Wire the second limit control in series with the boiler limit control.

• Set the second limit control at least 20 °F above the boiler limit control setting (maximum

setting 240 °F).

A low water cutoff device is required when boiler is installed above radiation level or by

certain state or local codes or insurance companies. Use low water cutoff designed for water

installations. Electrode probe-type is recommended. Purchase and install in tee in supply piping

above boiler.

If boiler is connected to heating coils located in air handling units where they

can be exposed to refrigerated air, use flow control valves or other automatic

means to prevent gravity circulation during cooling cycle. Circulation of cold

water through the boiler could result in damage to the heat exchanger, causing

possible severe personal injury, death or substantial property damage.

Do not remove either of the GV internal pumps for use elsewhere in the

system. Both pumps are required for proper operation. Removing a pump

will cause the boiler to malfunction. Substantial property damage could result.

Never install another pump in series with the GV boiler. Forced

flow can cause improper operation of the boiler controls. Substantial property

damage could result.