59Part number 550-141-850/0699

• Installation • Start-Up • Parts • Maintenance

Water piping

1. Check the boiler interior piping and all system piping for signs of leaks.

2. Repair any leaks before proceeding.

Eliminate all system leaks. Continual fresh makeup water will reduce

boiler life. Minerals can build up in sections, reducing heat transfer, overheating

cast iron, and causing section failure.

Do not use petroleum-based cleaning or sealing compounds in boiler

system. Severe damage to boiler will occur, resulting in substantial property

damage.

Condensate drain system

1. Inspect the condensate trap hose for deterioration.

2. Check for any obstructions in the trap hose by squeezing the tubing.

3. If there is any doubt the condensate drain system is flowing freely, remove the clamp and hose

from the bottom of the vent starter tee. Slide a funnel outlet into the trap hose and pour water

through. It should exit at the termination of the condensate drain line.

4. If the owner’s monthly inspection of the condensate drain system has indicated a tendency for

the trap to run dry, install a condensate drain line check valve kit, available through

your Weil-McLain distributor. See installation instructions for check valve kit in this manual

section.

Annual start-up —

inspect

Annual start-up —

start-up

Start-up procedure

1. Follow the instructions in manual Section VII.

2. Verify cold fill pressure is correct and that fill system is working properly.

3. Verify antifreeze level (if used) is at the right concentration and that inhibitor level is

correct.

4. Check gas piping, per manual Sections V and VIb, verifying no indications of leakage and

all piping and connections are in good condition.

5. Read the Lighting instructions (Figure 25 or 26 of this manual or on boiler label) applying

to the boiler (ensuring the instruction applies to the gas valve installed in the boiler).

6. Start the boiler following the Lighting instructions and manual Section VIId.

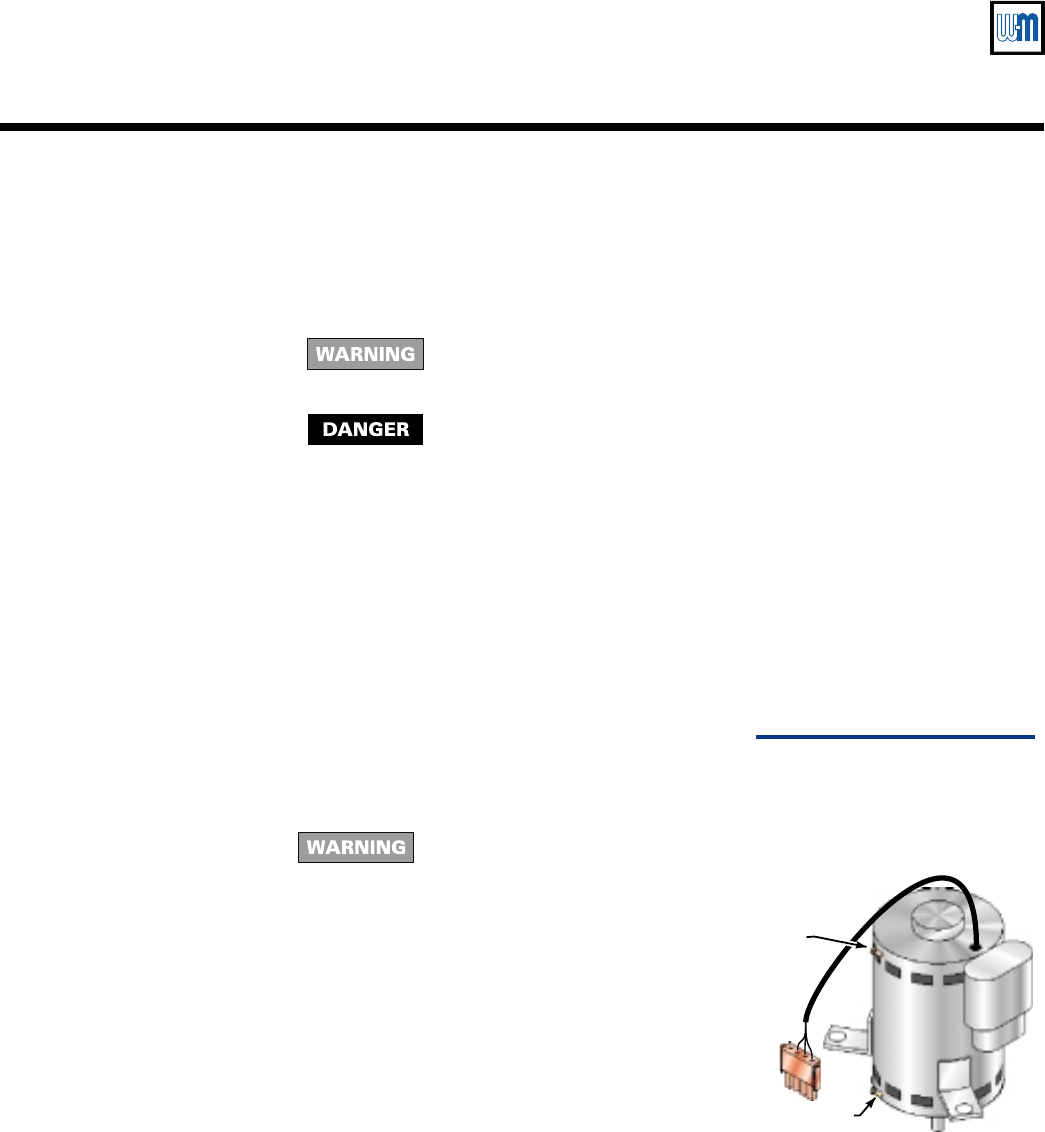

Figure 27 Blower motor

Oil

cup

Oil cup

85037

Annual start-up —

service

Blower motor (Figure 27)

1. With boiler power OFF, place a few drops of S.A.E.

20 motor oil in each of the two oil cups.

Use only S.A.E. 20 motor oil to

lubricate the blower motor. Do not

use universal household oils. Motor

could be damaged, resulting in

possible severe property damage.

Oiled-bearing circulators

1. Both of the circulators installed in the boiler are water-

lubricated. No oiling is required.

2. Check other circulators in the system. Oil any

circulators requiring oil, following circulator

manufacturer’s instructions. Over-oiling will damage

the circulator.