Part number 550-141-850/069932

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manualGOLD GV Water boiler series 3 — manual

GOLD GV Water boiler series 3 — manual

Water piping — radiator systemIIIf

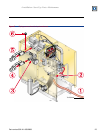

Figure 12a Radiator system — zone-valve

zoning

Zone 2

Zone 1

85013b

Cold

water

fill

GV Boiler

12"

max

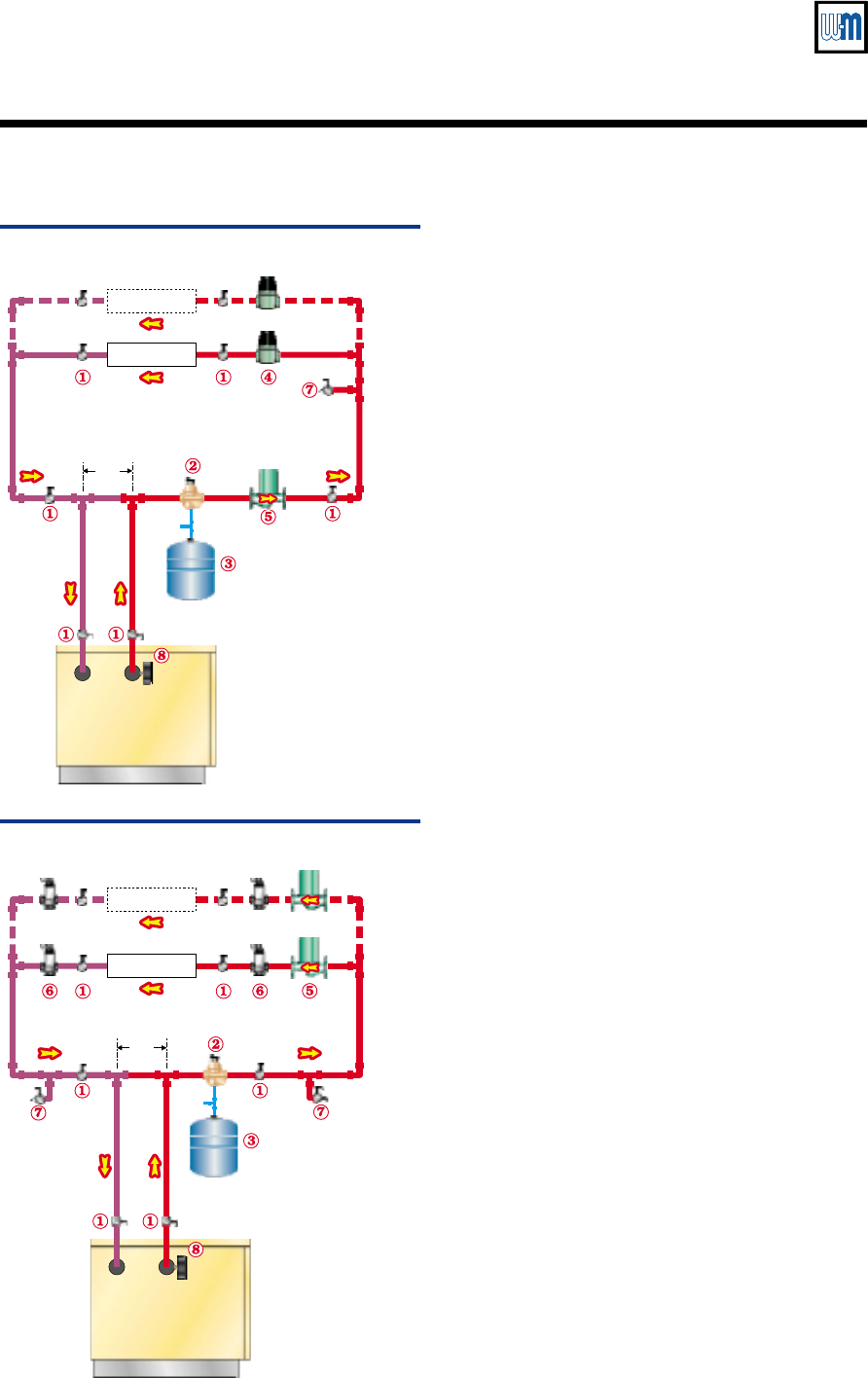

Figure 12b Radiator system — circulator

zoning

Zone 2

Zone 1

85017

Cold

water

fill

GV Boiler

12"

max

Legend

1 Boiler isolation valves

2 Automatic air vent (with diaphragm-type

expansion tank), or connect to tank fitting

(closed-type expansion tank).

3 Diaphragm- or bladder-type expansion tank, if

used. (For closed-type expansion tank, pipe

from top of air separator to tank fitting as in

Figure 10.)

4 Zone valve

5 System or zone circulator

6 Flow/check valve

7 Hose bibb purge valve

8 Boiler pressure/temperature gauge

Radiator system piping

Apply Figure 12a (zone-valve zoning) or 12b (circulator

zoning) to systems using standing cast iron radiators.

This applies to gravity water systems and converted steam

systems using columnar, tubular or recessed cast iron

radiators.

The suggested piping for zone-valve zoning radiator

systems differs from baseboard systems because of the

high water content of cast iron radiators. The GV internal

circulators automatically regulate supply and internal

bypass flow based on the temperature of the water

returning to the boiler. At the start of many heating cycles

in a radiator system, the water in the radiators is cool. So

the boiler would slow down system flow rate while

sending out relatively hot water. This could cause heat

distribution problems. Install a separate system circulator

as shown in Figure 12a when zoning with zone valves.

The separate circulator assures a relatively constant

temperature drop through the system.

The boiler internal circulators must be left in the boiler.

They cannot be removed for use a a zoning circulator.

Provide a circulator for each zone when circulator zoning,

and pipe the system as in Figure 12b.