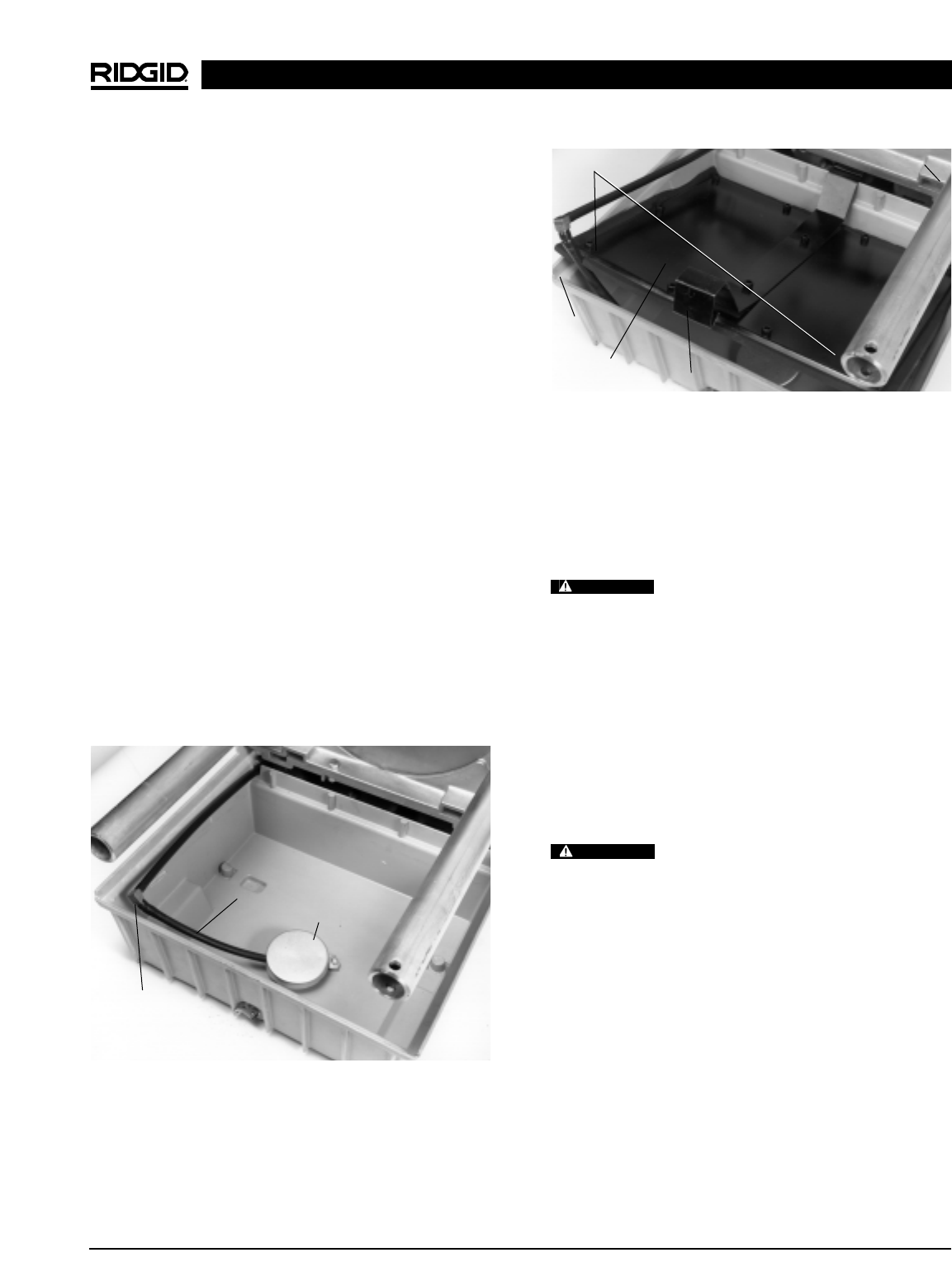

Figure 5B – No. 1460 Oil Pan Cover

Mounting Machine To Bench

1. If a stand is not used, the machine should be

mounted to a stable bench. To mount the unit on a

bench, use four (4)

5

/

16

″ bolts in holes provided at each

corner of machine base. Base dimensions are shown

in Figure 2.

Failure to mount the threading machine to

a stable stand or bench may result in tipping and serious

injury.

Transporting Machine with

No. 1406 Stand

1. Install 1460 Oil Pan Cover to prevent oil spillage.

2. For ease of transporting, turn hand crank counter-

clockwise and fold stand into a compact package.

3. Lift handles (front and rear) and skid bars are provided

for transportation on stairways, over rough terrain

and in and out of trucks, vans and station wagons.

Use two persons on stairs.

4. The front handle is for control on stairs and wheel-

barrow like operation.

5. The rear handle is for an assist on stairs, lifting in and

out of vehicles and movement over flat surfaces in the

operational position.

Transporting Machine with a Tow

Motor, Material Lift or Crane

1. Place tow motor forks below base of machine and

above cabinet or tray.

2. Loop a sling over a 2″ piece of pipe as shown in

Figure 6 and lift machine with a lift or crane.

3. Place a sling around machine and top stand rails

and lift machine with a material lift or crane.

Ridge Tool Company

7

Mounting Machine to No. 1406 Folding

Wheel Stand

1. Raise rear handle of stand to a vertical position and

tighten mounting bolts.

2. Using hand crank, raise stand to its operating height.

Place machine on stand with carriage away from

wheels (Figure 4). Insert four

1

/

4

″ – 20 bolts through

rails into machine base. Tighten bolts.

Installing No. 1460 Oil Pan Cover

NOTE! No. 1460 Oil Pan Cover installs in machine oil

reservoir and prevents oil spill during transporta-

tion. No. 1460 is shipped with No. 1406 Folding

Wheel Stand and is available as an accessory.

1. With oil reservoir drained, disconnect filter and oil

line.

2. Attach elbow fitting and oil line extension to existing oil

line (Figure 5A).

3. Reattach oil line to filter and the filter to reservoir

base.

4. Install oil pan cover with oil line positioned as in

Figure 5B.

5. Set chip pan in place and machine is ready for trans-

port.

NOTE! Chip pan will not lock into position. This is a re-

minder that the oil pan cover is installed.

Figure 5A – No. 1460 Oil Pan Cover

1822-I Pipe and Bolt Threading Machine

Oil Filter

Line Extension

Elbow Fitting

Rear Latch

Push

Oil Line

Notch

Oil Pan

Cover

Front Latch

WARNING

WARNING