1822-I Pipe and Bolt Threading Machine

Figure 14 – Checking Thread Length

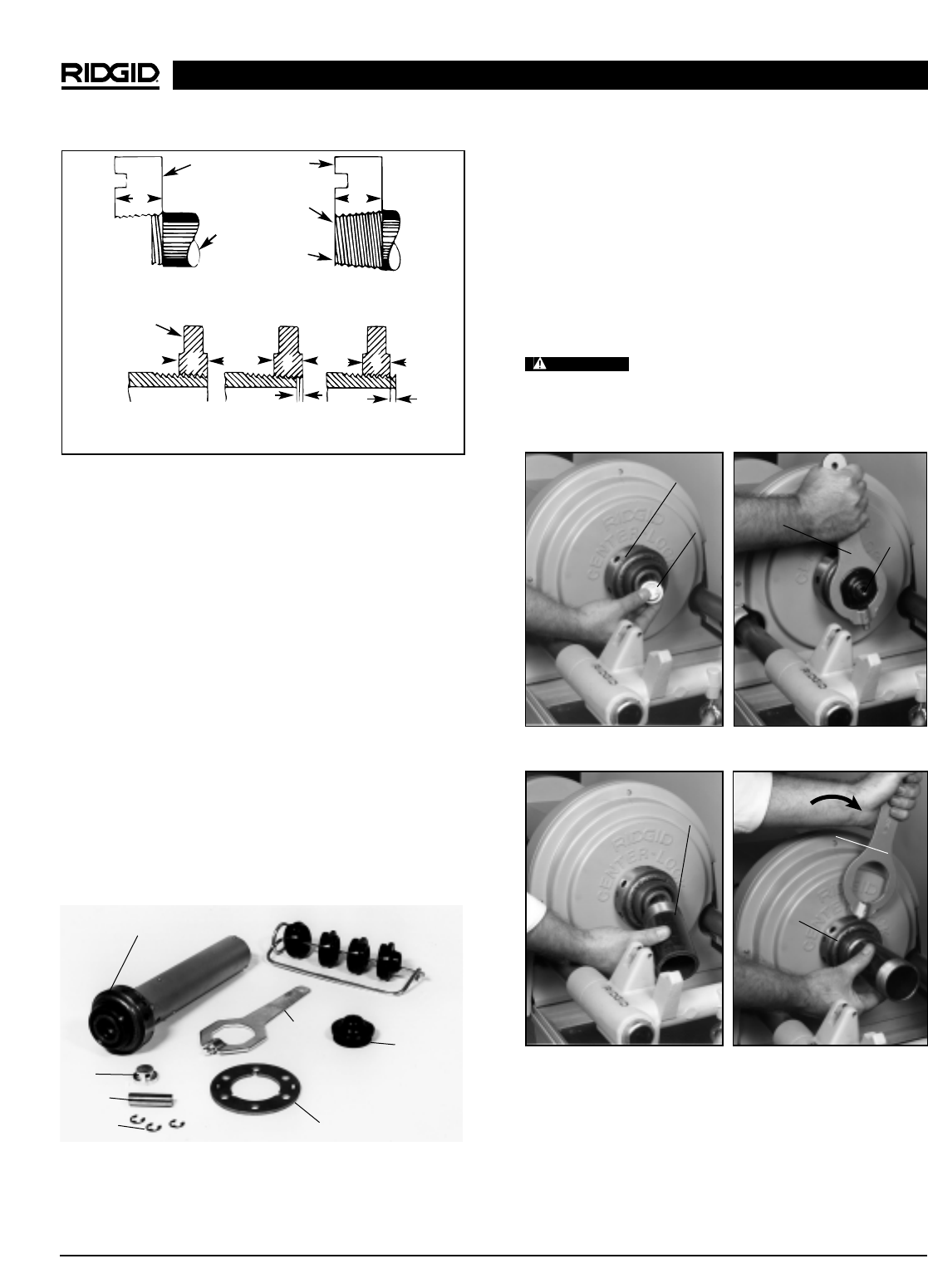

No. 819 Nipple Chuck and

No. 839 Adapter Kit

Installation

1. The machine utilizes No. 819 Nipple Chuck and ex-

isting size adapter. Mounting requires a No. 839

Adapter Kit (Figure 15).

2. Assemble the 819 nipple chuck/839 Adapter Kit as

described in the instructions provided with the kits.

3. Turn control switch to the OPEN position and de-

press foot switch to fully open chuck.

NOTE! Make sure that special front retainer plate is

installed to allow for use of 819 and 839 adapter.

4. Insert the adapted No. 819 Nipple Chuck, tube end

first, into chuck of No. 1822-I Threading Machine. Ro-

tate assembly until key on 839 slides into notch.

Figure 15 – No. 819 and No. 839 Assembly

Ridge Tool Company

14

Nipple Threading Procedure

1. Ream, thread and cut pipe to desired length using

standard procedures.

2. Install No. 819 and 839 adapter (Figure 16).

3. Position insert with small end toward adapter for

1

/

8

″ to

3

/

4

″ pipe, large end toward adapter for 1″ pipe and no

insert for pipe 1

1

/

4

″ and up.

4. Install proper adapter and tighten with wrench.

Remove wrench before starting machine.

5. Screw nipple into adapter, ream and thread other

end (Figure 17). Insert wrench into collar and re-

lease nipple.

Figure 16 – Installation Insert and Adapters

Figure 17 – Installing and Releasing Nipples

W

W

D

D

D

Die

Pipe

Die

Pipe

A - Full Width Die Thread

Starting to Cut Thread

Flush

(Basic Size)

One Turn Large

(Maximum Size)

One Turn Small

(Minimum Size)

Thin Ring

Gage

Completed Thread

Die Flush

With End

of Pipe

B - Checking Threads Within Pipe Gage

No. 819 Nipple Chuck

Front Retainer Plate

Wrench

Insert

Pipe

Adapter

Pin

Retaining

Rings

Nipple Chuck

Insert

Adapter

Wrench

Nipple

Release

Collar

Wrench

WARNING