Ridge Tool Company

21

2. Install the E-clips and washers on the front jaws.

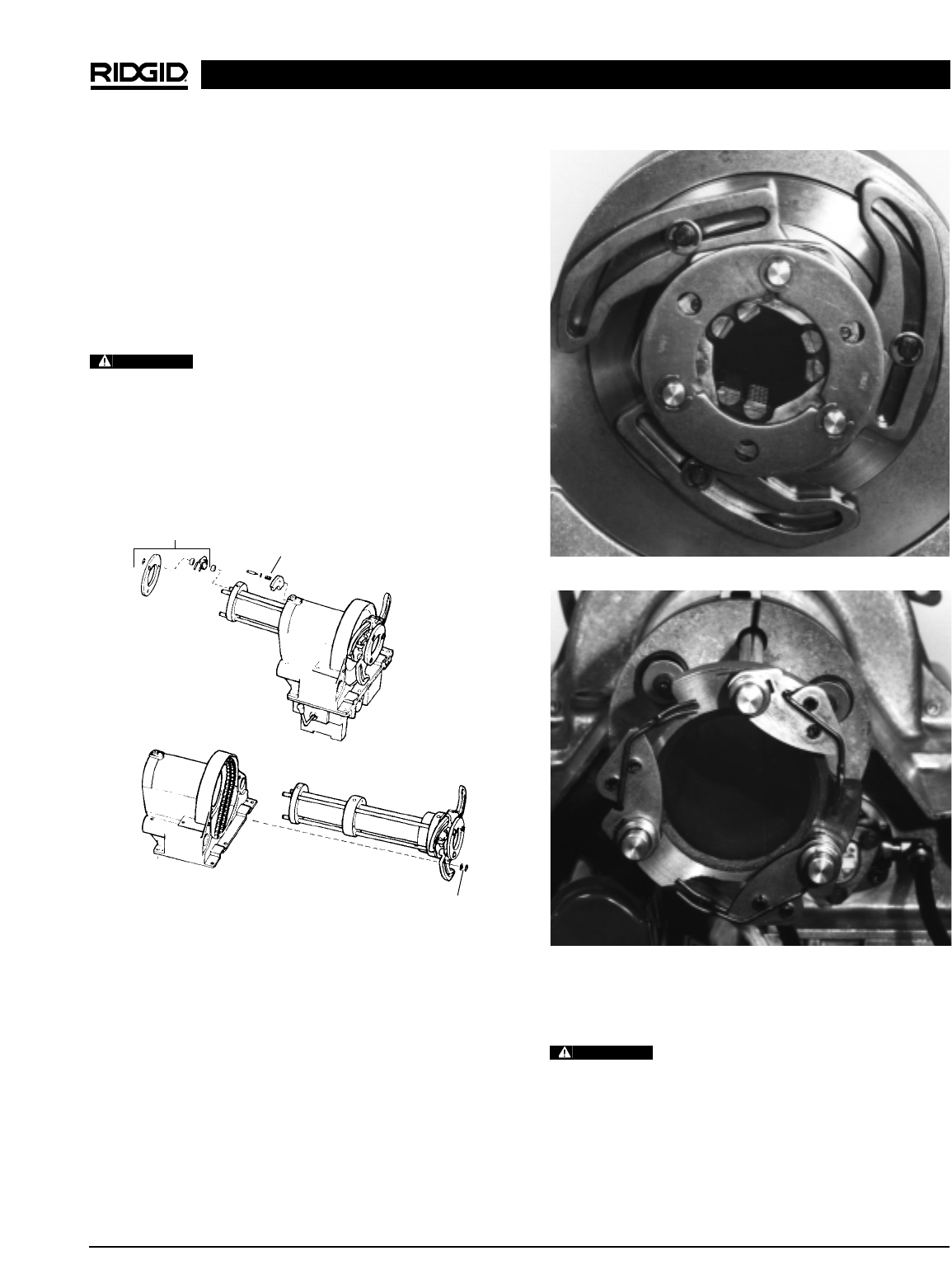

3. Reassemble the three (3) brake shoes.

NOTE! Tighten shoulder bolts until they bottom out.

4. Reassemble rear centering assembly using new

spacers and rear jaws supplied with the kit.

NOTE! Rear jaws must be oriented as shown for right

hand threading. (Refer to Figure 27.)

5. Install top and front covers.

Do not operate machine with covers re-

moved.

NOTE! Once the machine is fitted with the new kit to

thread plastic coated pipe, it is also capable of

threading steel and galvanized pipe sizes

1

/

2

″ –

2″. If smaller sizes than

1

/

2

″ pipe are required, the

original front and rear jaw assemblies must be in-

stalled.

Figure 26 – Removing Brake Shoes

Figure 27A – Jaw Orientation

Figure 27B – Jaw Orientation

Machine Storage

Motor-driven equipment must be kept in-

doors or well covered in rainy weather. Store the machine

in a locked area that is out of reach of children and peo-

ple unfamiliar with threading machines. This machine

can cause serious injury in the hands of untrained users.

1822-I Pipe and Bolt Threading Machine

WARNING

Step 3

Step 2

Step 1

WARNING