bracket is held in place by the axle shaft. Slide a

wheel onto the axle. Slide a flat washer over the axle

and install a cotter pin to hold the wheels on the axle.

5. Mount machine to the stand using four (4) bolts that

mount into each corner of the base.

For proper balance and operation, RIDGID

machines must be mounted through the appropriate

holes in the rails (Figure 3).

Ridge Tool Company

6

shown in the detail drawing. Use the four (4)

3

/

8

″ - 16

x 2

1

/

2

″ hex bolts to secure the legs to the cross-mem-

ber. Adjust the two halves of the stand stop to the

proper distance to fit into the rear legs on the stand.

The stand stop bracket is not required or supplied with

the No. 100 Leg and Tray Stand.

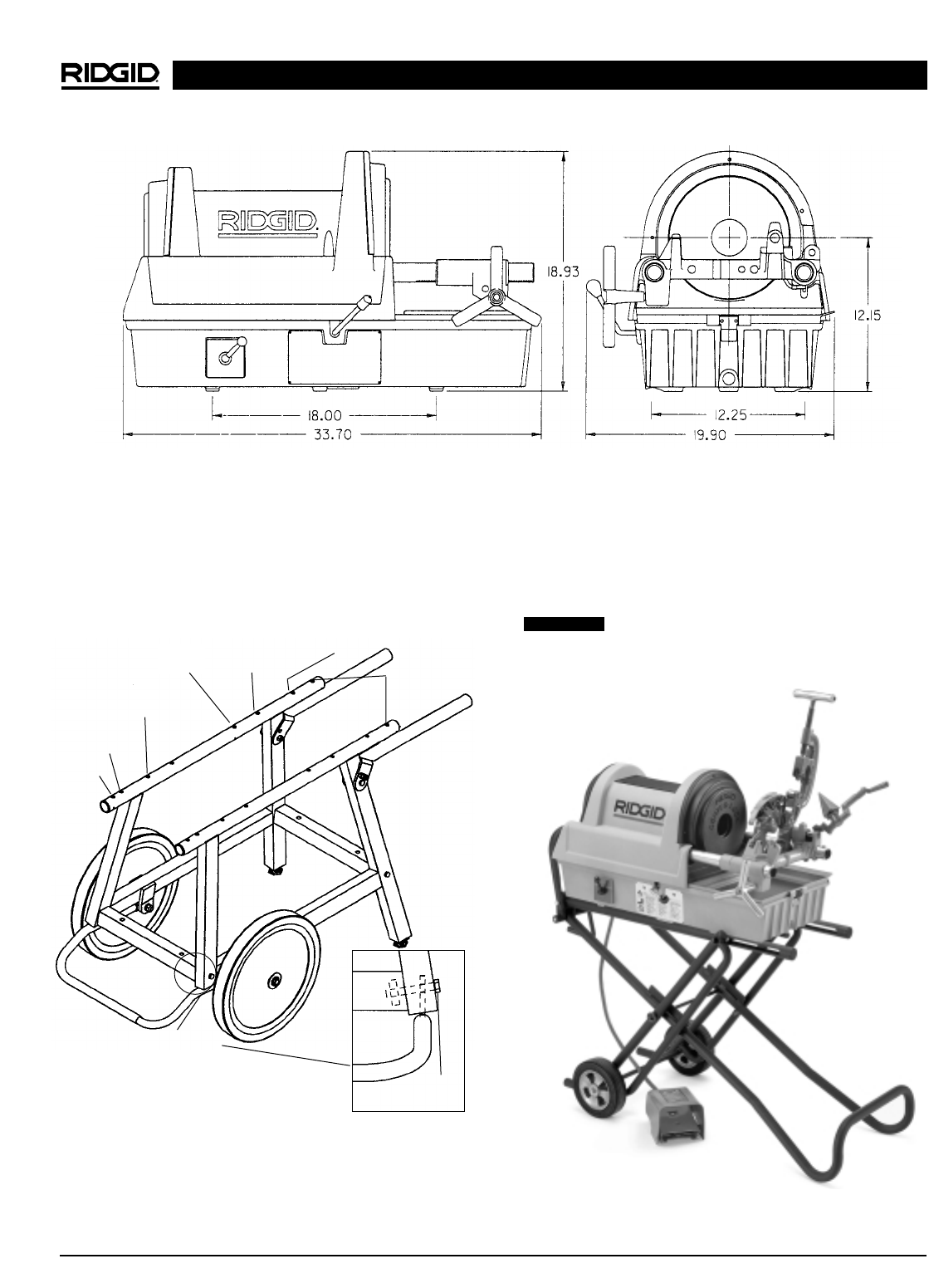

Figure 3 – Stand Assembly

NOTE! Insert axle into frame and secure it with a

1

/

2

″

lock washer and nut.

4. Position stand stop bracket so that the end of the

1822-I Pipe and Bolt Threading Machine

Figure 2 – Machine Dimensions

Figure 4 – No. 1406 Folding Wheel Stand

CAUTION

535

1224

(Rear)

1224

(Front)

535 (Front)

Detail Section

300 Compact

1233, 1822 (Rear)

300 Compact

1233, 1822

(Front)

3

/

8

″ - 16 x 2

1

/

2

″ Bolt

4 Required

535

Automatic

535

Automatic