29

Start-Up - 2:1 Electronic Modulation

1. Send Unit to High Fire

Turn the temperature

selector to its maximum

setting to send the unit

to high fire.

2. Check the High Fire Manifold

Pressure

With the unit at high fire, use a manometer to measure

the burner manifold pressure at the manifold pressure

test port. See the Gas Train Layout in the Reference

section for the manifold pressure test port location.

The recommended high fire manifold pressure is

3-1/2in. wg for natural gas and 10in. wg for

LP gas.

If needed, use the high

fire adjustment screw on

the shut-off gas valve to

adjust the high fire manifold

pressure. Counterclockwise

rotation will decrease the

gas pressure and clockwise

rotation will increase the gas

pressure.

3. Send Unit to Low Fire

Remove and isolate one wire from the modulating gas

valve terminal to send the unit to low fire.

4. Check the Low Fire Manifold Pressure

With the unit at low fire, use a manometer to measure

the burner manifold pressure at the manifold pressure

test port. See the Gas Train Layout in the Reference

section for the manifold pressure test port location.

The recommended low

fire manifold pressure is

7/8in. wg for

natural gas and

2-1/2in. wg

for LP gas.

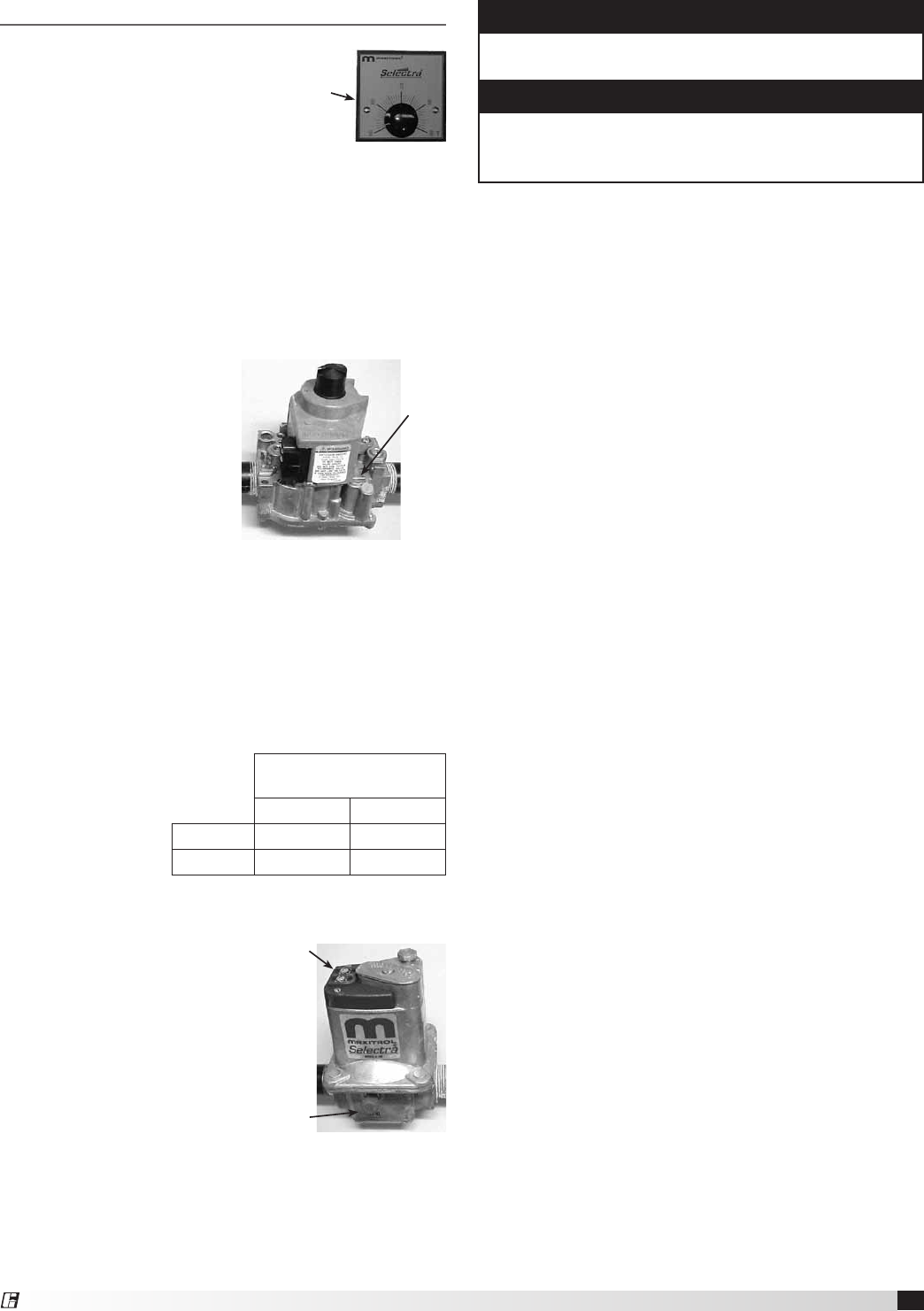

If needed, use the low fire adjustment screw on the

modulating gas valve to adjust the low fire manifold

pressure. Counterclockwise

rotation will decrease the

gas pressure and clockwise

rotation will increase the gas

pressure.

Once the low fire is set,

reattach the disconnected

wire to the modulating valve

and reset the temperature

selector.

Low Fire

Adjustment

Terminal

NOTE

The low fire manifold pressure should always be

rechecked after adjusting the high fire.

NOTE

Once the high and low fire manifold pressures are

properly set, reset the discharge air temperature to

the desired setting.

2:1 Manifold Pressure

(in. wg)

Natural Gas LP

Low Fire

7/8 2-1/2

High Fire

3-1/2 10

High Fire

Adjustment

Temperature

Selector

®

Model IG / IGX Make-Up Air