MODEL SOLU COMP II SECTION 8.0

TROUBLESHOOTING

8.4.5 Measurement seems wrong.

A. If sensor is being installed for the first time, check the wiring connections. See Section 3.2.

B. Verify that the sensor is completely immersed in the process liquid.

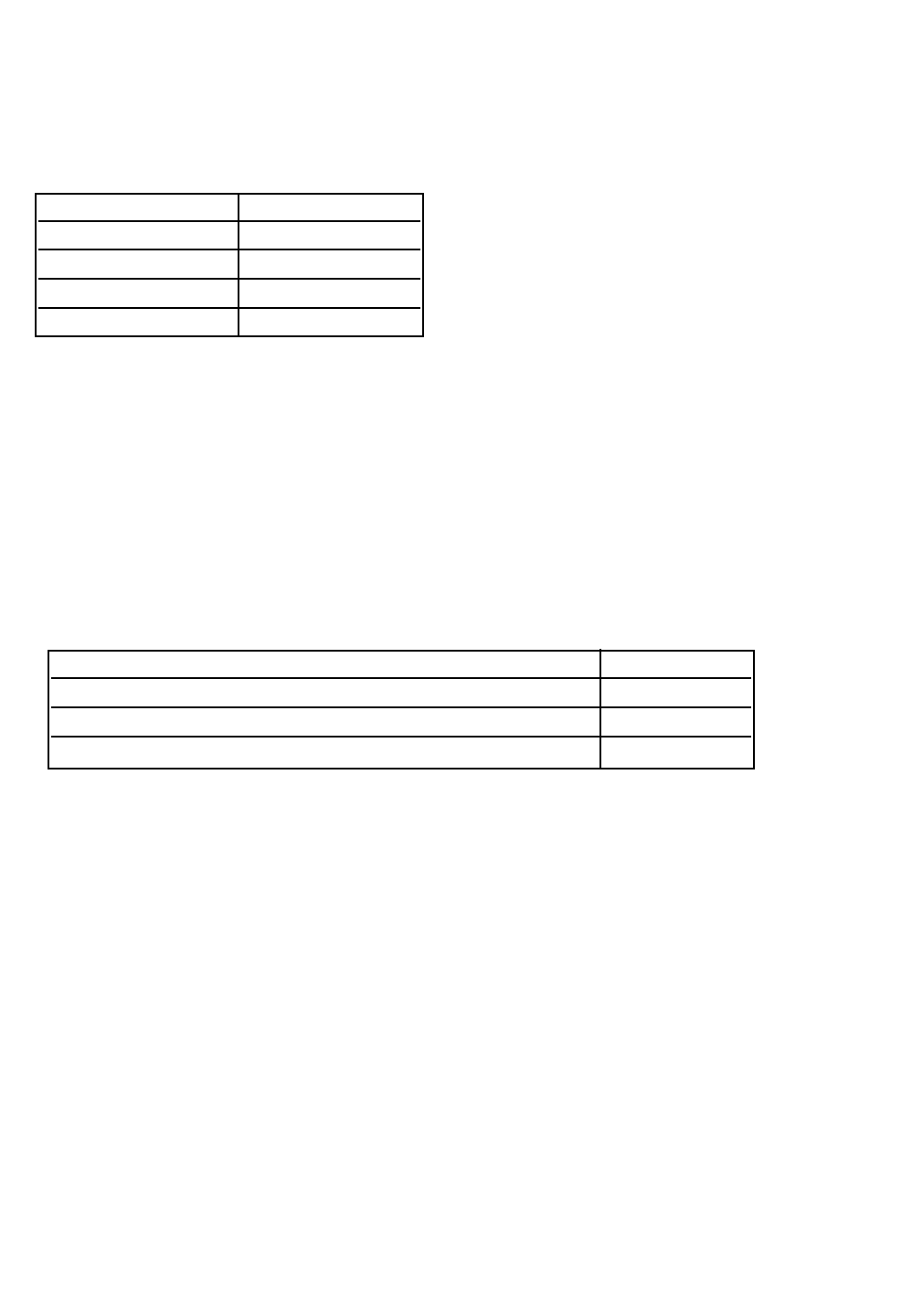

C. Be sure the sensor has a cell constant appropriate for the liquid being measured. Refer to the table below.

D. Remove the sensor from the process liquid. Rinse with water. Inspect the sensor for obvious signs of damage

such as cracks or chips. Verify that the vent holes are not blocked. If the sensor is dirty or fouled, clean it.

Usually, rinsing the sensor with a forceful stream of water is adequate. A soft bristle brush, like a toothbrush,

may help dislodge solids. Do not use a wire brush. For advice concerning the use of chemical solvents, refer

to the sensor instruction manual.

E. Check the sensor for continuity and leakage. See Section 8.2.3

F. If the resistances are not in limits, replace the sensor.

G. If the resistances are in limits, check the analyzer. See Section 8.7.

8.5 TROUBLESHOOTING WHEN NO ERROR MESSAGE IS SHOWING — GENERAL

8.5.1 Current Output Too Low.

Load resistance is too high. Maximum load is 600 Ω.

8.5.2 Alarm Relays Do Not Work

A. Verify the relays are properly wired.

B. Replace power supply PCB. See Table 7-1 or 7-2.

8.5.3 Display is Unreadable.

While holding down the MENU key, press or until the display has the correct contrast.

Conductivity,

µµ

S/cm Cell constant, /cm

0.0 - 50 0.01

5 - 500 0.10

50 - 5000 1.0

500 - 20,000 10

Problem See Section

Current output is too low 8.5.1

Alarm relays do not operate when setpoint is exceeded 8.5.2

Display is unreadable — too faint or all pixels dark 8.5.3

71