3.2 POWER, ALARM, OUTPUT, AND SENSOR CONNECTIONS

The Solu Comp II is available in two mounting configurations.The positions of the power, alarm, output, and sen-

sor terminal blocks are different in each. Refer to the table to find the correct drawing.

For best EMI/RFI protection use

shielded output signal cable

enclosed in an earth-grounded

metal conduit. Connect the

shield to earth ground at termi-

nal 4 on TB1.

AC wiring should be 14 gauge or greater. Provide a switch or breaker to disconnect the analyzer from the main power

supply. Install the switch or breaker near the analyzer and label it as the disconnecting device for the analyzer.

Keep sensor and output signal wiring separate from power wiring. Do not run sensor and power wiring in the same

conduit or close together in a cable tray.

NOTE

For sensors without solution ground, please use the RC kit included with the instrument.

MODEL MOUNTING POWER FIGURE

1055pH-01-10 Panel 115/230 Vac 3-2

1055pH-02-10 24 Vdc 3-3

1055pH-01-11 Surface/Pipe 115/230 Vac 3-4

1055pH-02-11 24 Vdc 3-5

WARNING: RISK OF ELECTRICAL SHOCK

AC connections and grounding must be in compliance

with UL 508 or local electrical code. DO NOT apply

power to the analyzer until all electrical connections are

verified and secure.

SECTION 3.0.

WIRING

3.1 PREPARING CONDUIT OPENINGS

3.2 POWER, ALARM, OUTPUT, AND SENSOR

CONNECTIONS

MODEL SOLU COMP II SECTION 3.0

WIRING

3.1 PREPARING CONDUIT OPENINGS

The number of conduit openings and the location depend on

the model.

Conduit openings accept 1/2-inch conduit fittings or PG 13.5

cable glands. To keep the case watertight, block unused

openings with NEMA 4X or IP65 conduit plugs.

NOTE

Use watertight fittings and hubs that comply with the

requirements of UL514B. Connect the conduit hub to the

conduit before attaching the fitting to the analyzer (UL508-

26.16).

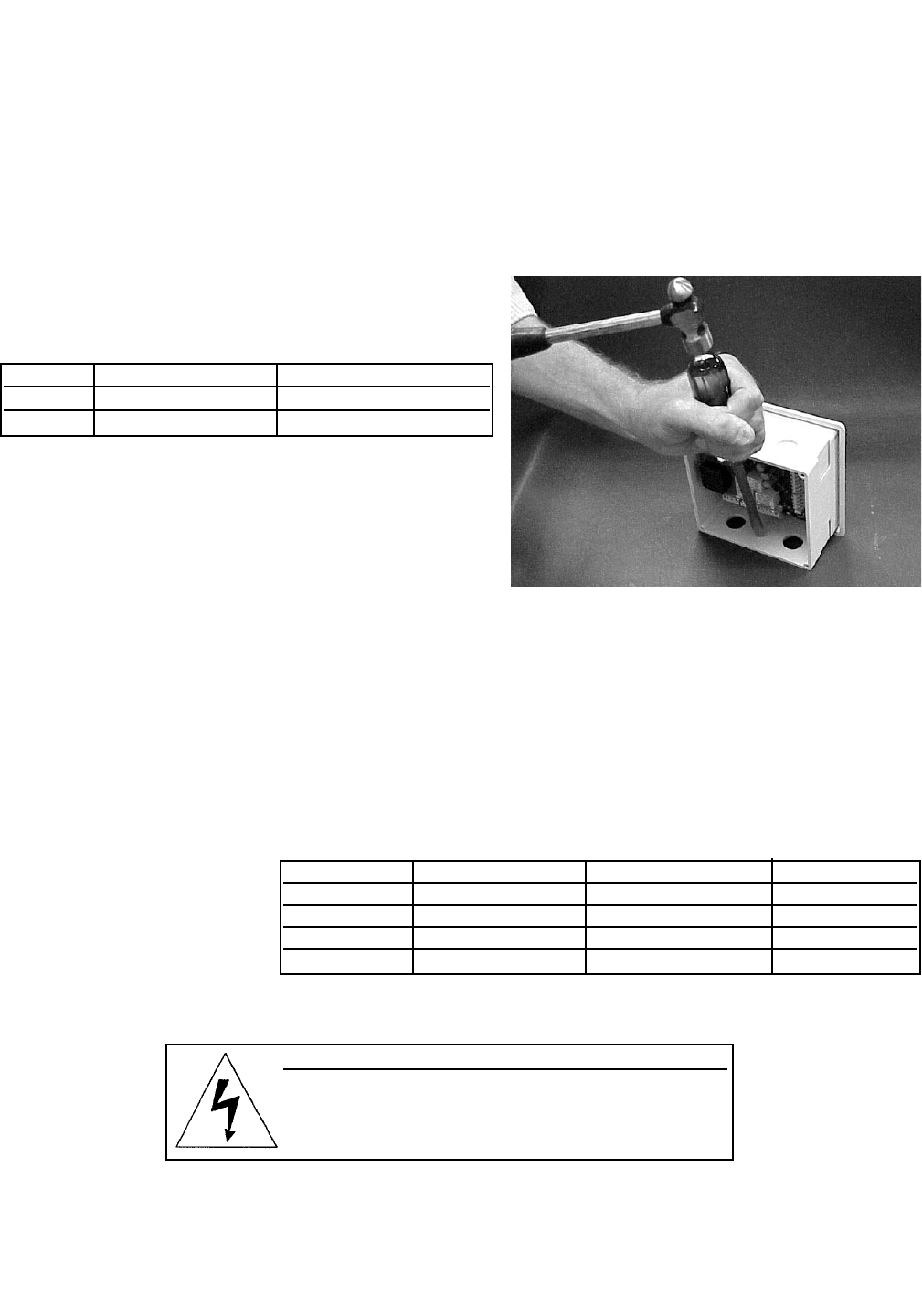

Figure 3-1 shows how to remove the knockouts. The knockout grooves are on the outside of the case. Place the

screwdriver blade on the inside of the case and align it approximately along the groove. Rap the screwdriver sharply

with a hammer until the groove cracks. Move the screwdriver to an uncracked portion of the groove and continue

the process until the knockout falls out. Use a small knife blade to remove the flash from the inside of the hole.

FIGURE 3-1. Removing the Knockouts

Model Description Conduit openings

1055-10 panel mount two open, three knockouts

1055-11 surface or pipe mount three open, no knockouts

15