Moisture/Liquid Indicator — A clear flow of liquid

refrigerant indicates sufficient charge in the system. Bubbles

indicate undercharged system or the presence of noncon-

densables. Moisture in the system measured in parts per mil-

lion (ppm) changes the color of the indicator:

Green — moisture below 45 ppm (dry)

Chartreuse — 45 to 130 ppm (caution!)

Yellow — moisture above 130 ppm (wet)

Change filter driers at the first sign of moisture in the sys-

tem. See Carrier Charging Handbook for more information.

IMPORTANT: Unit must be in operation at least

12 hours before moisture indicator can give an accu-

rate reading. With unit running, indicating element must

be in contact with liquid refrigerant to give a true

reading.

Filter Drier — Replace whenever the moisture/liquid in-

dicator shows moisture in the system.

Liquid Line Service Valve — Located immediately

ahead of the filter drier, this valve has a 1/4-in. flare con-

nection for field charging. With the liquid circuit shut, the

compressor can be used to pump the refrigerant down into

the high side. The refrigerant can then be stored there by

closing the compressor discharge valve.

Compressor Discharge Service Valve — Each

compressor has one.

Compressor Suction Service Valve — Each com-

pressor has one.

Protective Devices

COMPRESSOR PROTECTION

Overcurrent — Each compressor has one manual reset, cali-

brated trip, magnetic circuit breaker. Do not bypass connec-

tions or increasethe size of thecircuit breaker to correct trouble.

Determine the cause and correct it before resettingthe breaker.

Overtemperature — Each 06D compressor has an internal

protector to protect it against excessively high discharge gas

temperatures. Each 06E compressor has an external dis-

charge gas thermostat. See Fig. 62. They will reset, but the

circuit will automatically be locked out by the control board.

Unit must be manually reset by interrupting control power.

Crankcase Heater — Each compressor has a crankcase heater

to prevent absorption of liquid refrigerant by oil in the crank-

case when the compressor is idle. Since 115-v power for the

crankcase heaters is drawn from the unit control circuit, main

unit power must be on for the heaters to be energized.

IMPORTANT: After a prolonged shutdown or service

job, energize the crankcase heaters for 24 hours before

starting the compressor.

Compressor Lockout — If any of the safeties (compressor

internal thermostat [06D compressors only], high-pressure,

or low-pressure) trip, or if there is a loss of power to the

compressors, the compressors will be locked out. To reset

DJ,DW units, manually move the thermostat setting. To re-

set DK,DY,NB,NP units, consult the controls and trouble-

shooting literature for the appropriate unit for details.

EVAPORATOR-FAN MOTOR PROTECTION —Amanual

reset, calibrated trip, magnetic circuit breaker protects against

overcurrent. Do not bypass connections or increase the size

of the breaker to correct trouble. Determine the cause and

correct it before resetting the breaker.

CONDENSER-FAN MOTOR PROTECTION — Each

condenser-fan motor is internally protected against over-

temperature. They are also protected against a severe over-

current condition by manual reset, calibrated trip, magnetic

circuit breakers on acommon circuit.As with the circuit break-

ers, do not bypass connections or increase breaker size to

correct trouble. Determine the cause and correct it before

resetting the breaker.

HIGH-AND LOW-PRESSURE SWITCHES — See Fig. 62

for compressor mounting locations. Settings forthese switches

are shown in Table 11. If either switch trips, that refrigerant

circuit will be automatically locked out by the controls. To

reset, interrupt control power.

NOTE: When a pressure transducer is used, the low pres-

sure trip point is the same as the low-pressure switch.

Relief Devices — All units have relief devices to pro-

tect against damage from excessive pressures (i.e., fire).These

devices protect the high and low side.

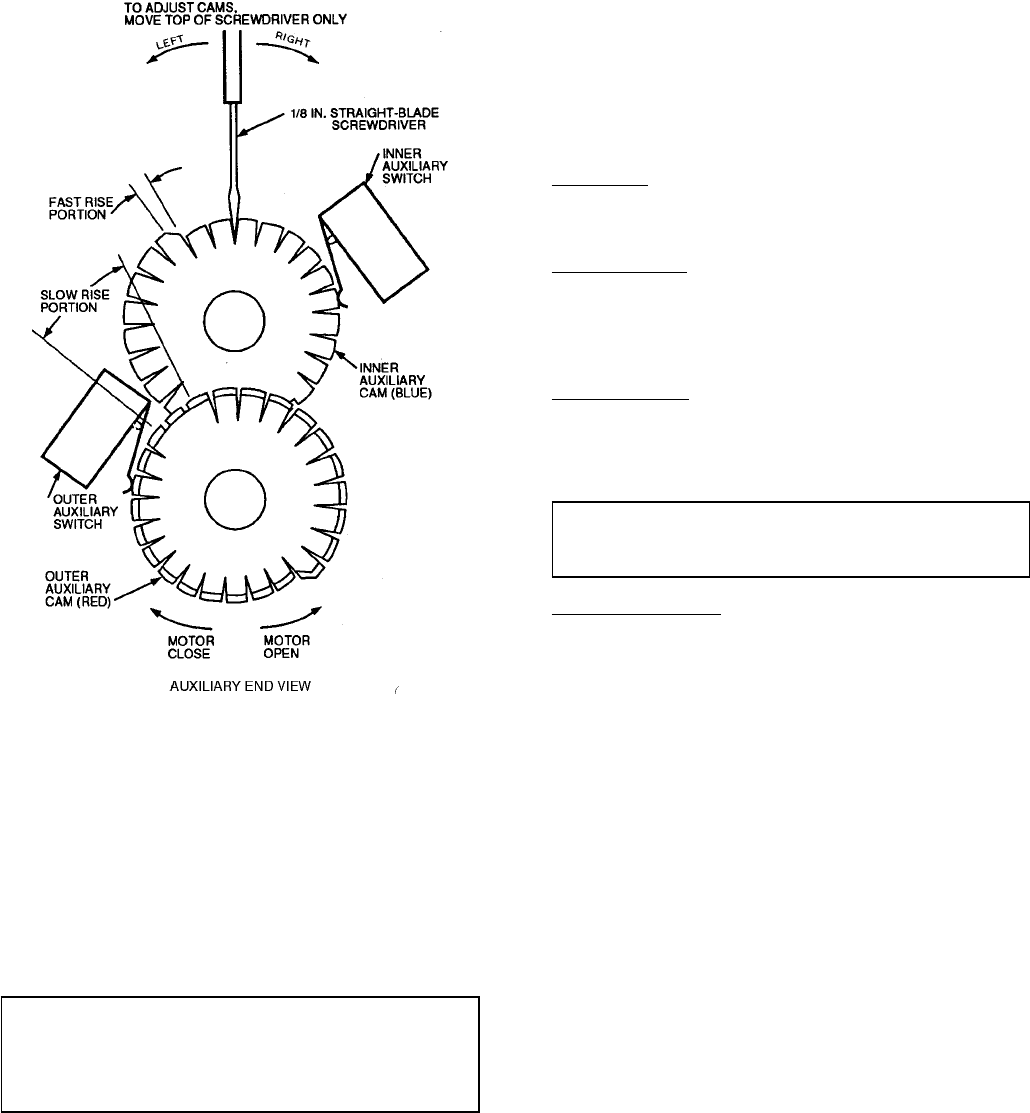

Fig. 61 — Auxiliary Switch Adjustment

51