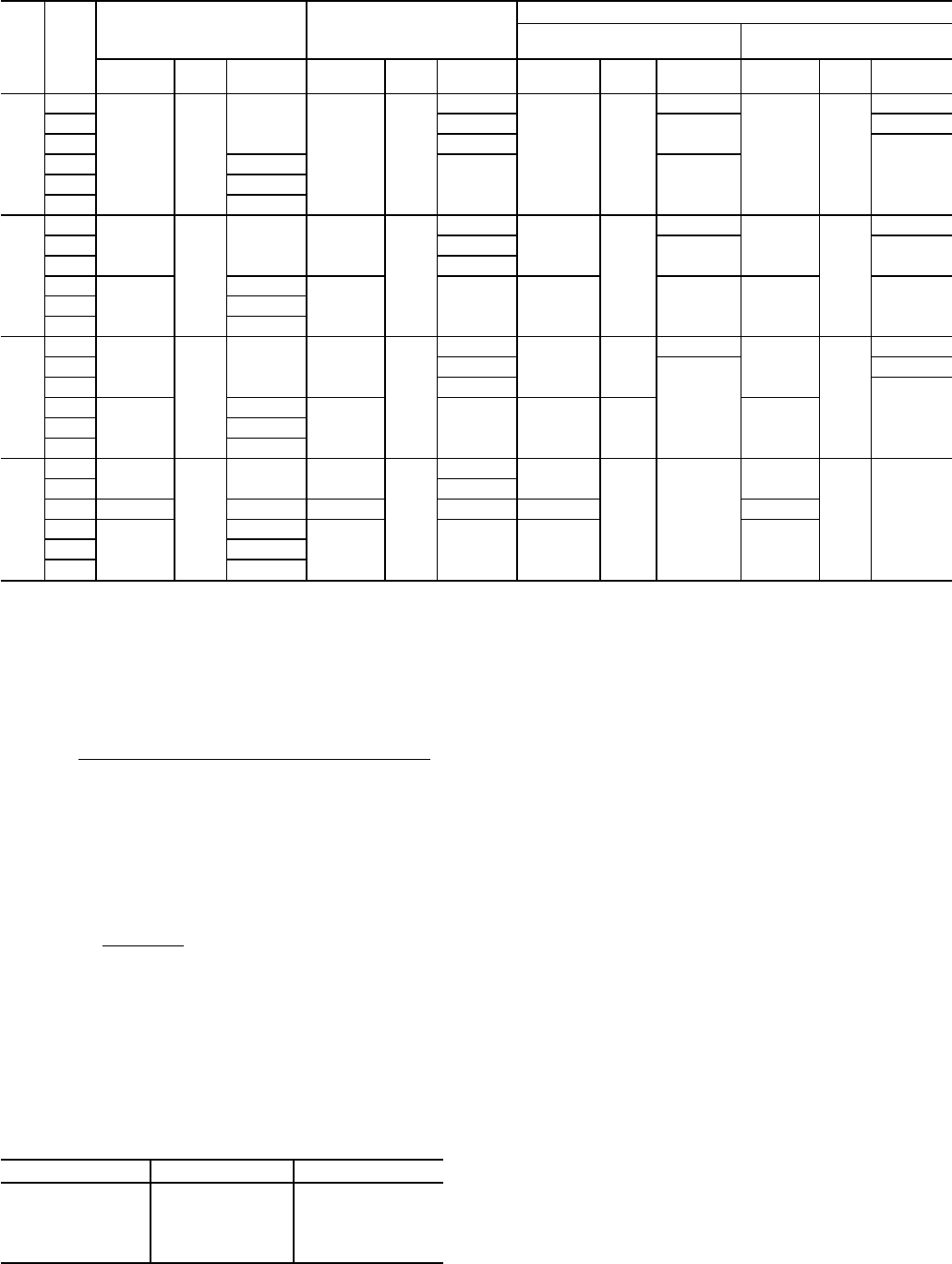

Table 9B — Field-Supplied Evaporator-Fan Pulley Data, 054-074 Units

IFM

Hp

IFM

RPM

MOTOR PULLEY BLOWER PULLEY

BELTS

48 Series and 50 Series

Horizontal Discharge Units

50 Series

Vertical Discharge Units

No.

Grooves

Type Size (in.)

No.

Grooves

Type Size (in.) Quantity Type Size (in.) Quantity Type Size (in.)

15

450

2 B5V

4.3

2 B5V

18.5

2 5VX

118

2 5VX

132

470 16.1

115

125

485 15.5

123

575 4.5

13.7 112650 5.1

725 5.7

20

405

3

B5V

4.3 3

B5V

18.5

3

5VX

123

3

5VX

132

470 16.1

118 125

485 15.5

575

2

4.5

2 13.7 2 115 2 123660 5.1

725 5.7

25

405

3

B5V

4.3 3

B5V

18.5

3 5VX

123

3

5VX

132

470 16.1

115

125

485 15.5

123

575

2

4.5

2 13.7 2 B5V 2700 5.5

725 5.7

30

470

4

B5V

4.3 4

B5V

16.1

4

5VX 118

4

5VX 123

485 15.5

530 3 4.7 3 15.5 3 3

600

2

5.5

2 15.5 2 2660 5.9

730 6.5

IFM — Indoor (Evaporator) Fan Motor

Check rotation of wheel with arrow on the fan housing.

Check fan speed with a strobe-type tachometer, or use this

formula:

motor rpm x motor sheave pitch diameter (in.)

Fan

=

Rpm

fan sheave pitch diameter (in.)

(Obtain motor rpm from the fan motor nameplate and read

sheave pitch diameters marked on the fan and motor sheaves.)

Example:

Nameplate motor rpm .................................................. 1760

Motor sheave pitch diameter (in.) .................................. 6.4

Fan sheave pitch diameter (in.) .................................... 12.4

1760 x 6.4

Fan Rpm = = 908 Rpm

12.4

The maximum allowable fan speed for the supply-air fan

is 900 rpm for 034 and 044 units and 750 rpm for 054-074

units. The maximum rpm for the power exhaust is 1300 rpm

for 034 and 044 units and 925 rpm for 054-074 units.

Excessive fan speed may result in condensate carryover from

the evaporator coil, fan motor overload, or wheel failure. See

Table 10 for Air Quantity Limits.

Table 10 — Air Quantity Limits (cfm)

UNIT SIZE MINIMUM MAXIMUM

034 6,000 15,000

044 8,000 20,000

054 10,000 25,000

064 12,000 30,000

074 14,000 30,000

Condenser Fans and Motors — Each unit has mul-

tiple condenser fans and motors; these are positioned at the

factory. See Fig. 32 for correct location of fan inorifice. Check

that fan propeller rotation is correct; it should be counter-

clockwise when facing the fans. If fan propeller rotation is

incorrect, switch motor leads.

Return-Air Filters — Check that the correct filters are

installed in the filter rack. See Tables 1A and 1B for quan-

tities and sizes. Access is through the door marked FILTER

SECTION. Do not operate the unit without return-air filters.

Economizer Inlet Screens — Check that they are in

place before operating the unit.

Economizer Dampers — With no power to the unit,

the economizer outdoor-air dampers should be fully closed.

Check by opening the access door marked FILTER SEC-

TION. On units with economizer, be sure economizer mini-

mum position is set at the desired setting. Be sure hood is

installed properly.

25% Outdoor-Air Damper — On units without econo-

mizer, be sure 25% outdoor-air damper is set at the desired

position. Also, be sure hood is installed properly.

40