PRE-START-UP

Unit Preparation —

Check to see that unit has been

installed in accordance with these Installation Instructions

and all applicable codes.

Compressor Mounting — Loosen compressor hold-

down bolts until sidewise movement of the washer under

each holddown bolt head can be obtained. Do not loosen

completely, as bolts are self-locking and will maintain

adjustment.

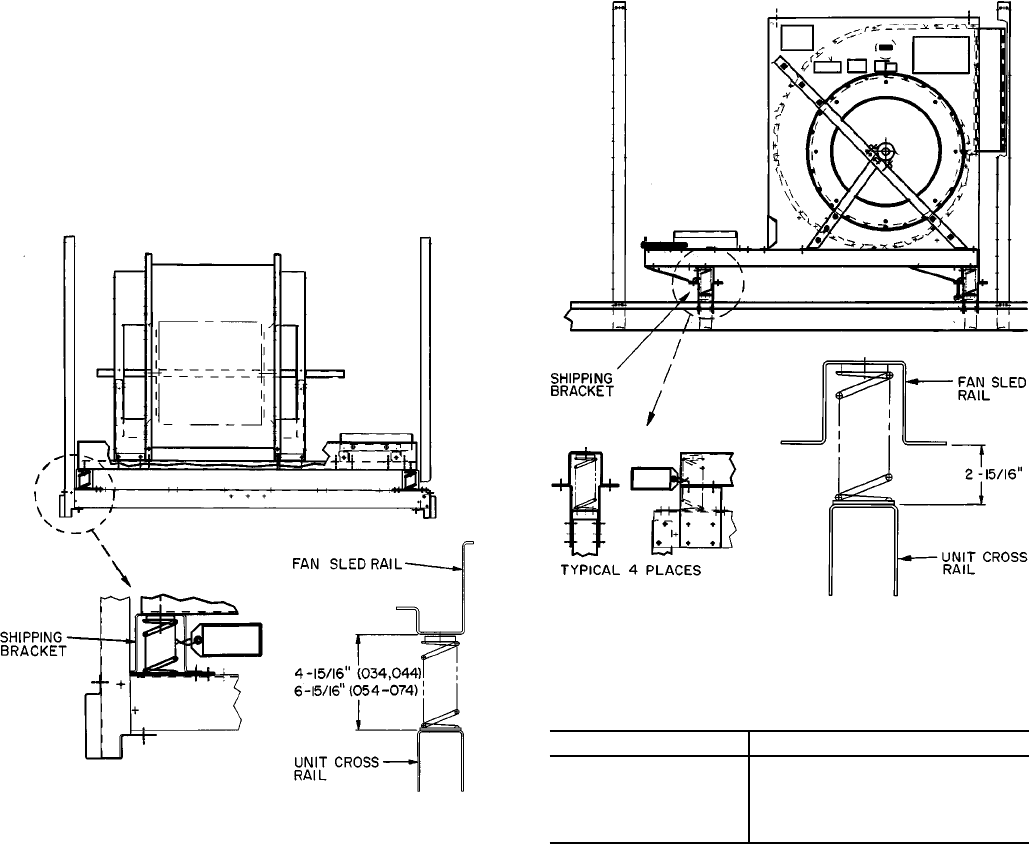

Evaporator-Fan Shipping Brackets — Evapor-

ator-fan shipping brackets (4 per unit) must be removed from

each corner of the fan sled before starting unit.

UNIT SIZES 034 AND 044

1. To remove brackets, raise fan sled by turning adjusting

bolt counterclockwise until spring is compressed slightly.

2. Remove screws holding shipping bracket to unit cross rail.

3. Remove shipping bracket (top of bracket is slotted so that

it will slide out).

4. After removing all shipping brackets, level fan sled using

the adjusting screws. On all 4 corners, dimension from

cross rail to fan sled should be as shown in Fig. 30.

UNIT SIZES 054-074 — To remove shipping brackets, re-

move the 6 screws holding each bracket to the cross rail.

There are 8 brackets per unit. See Fig. 30 or 31.

After removing all shipping brackets, level fan sled using

the adjusting screws. On all 4 corners dimension from cross

rail to fan sled should be as shown in Fig. 30 or 31.

Internal Wiring — Check all electrical connections in

the unit control box; tighten as required.

Refrigerant Service Valves — All units have a

Schrader-type service port on both suction lines. Be sure that

caps on the ports are tight. All units have discharge and suc-

tion service valves on each compressor and a service valve

on each liquid line. Be sure the valves are open before start-

ing unit.

Crankcase Heaters — The crankcase heaters must be

firmly locked into the compressors. The crankcase heaters

are energized when there is power to the unit. Crankcase

heaters must be energized with discharge and suction serv-

ice valves open for at least 24 hours prior to unit start-up in

order to remove liquid refrigerant from the compressor crank-

case and to prevent oil foaming.

Compressor Oil — Check that compressor oil is vis-

ible in the sight glass of the compressor.All units are factory

charged with oil. See Table 8. Observe oil level closely at

start-up. If oil level is below the sight glass and cannot be

seen, add oil until the level is approximately 1/4 of sight

glass. See Carrier Standard Service Techniques, Refriger-

ants section, for procedures to add or remove oil.

Table 8 — Oil Charge

UNIT SIZE OIL CHARGE (pints)

034 16 ( 8 each circuit)

044 28 (14 each circuit)

054 33 (19 ckt 1, 14 ckt 2)

064 38 (19 each circuit)

074 38 (19 each circuit)

Fig. 30 — Shipping Brackets; 034,044 Units and

50 Series Vertical Discharge 054-074 Units

Fig. 31 — Shipping Brackets; 48Series 054-074 Units

and 50 Series Horizontal Discharge 054-074 Units

38