Table 11 — Pressure Switch Settings (psig)

SWITCH CUTOUT CUT-IN

High 426 Ϯ 7 320 Ϯ 20

Low 27 Ϯ 467Ϯ7

Control Circuit, 115 V — This control circuit is pro-

tected against overcurrent by a 5-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Control Circuit, 24 V — This control circuit is pro-

tected against overcurrentby a 3.2-amp circuit breaker. Breaker

can be reset. If it trips, determine cause of trouble before

resetting.

Electric Heat (50 Series Units Only)

OVERCURRENT — Heaters are protected by fuses in the

power circuit, located in the heater control box. As with cir-

cuit breakers, determine the cause of fuses tripping before

replacing them. Do not replace with larger fuses. All fuses

are 60 amp.

OVERTEMPERATURE — Heaters are protected by limit

switches mounted in the heater box. They reset automati-

cally once they cool.

Gas Heat (48 Series Units Only)

LIMIT SWITCHES — The maximum supply-air tempera-

ture is controlled by a limit switch located in the gas section.

The limit is designed to trip at 100 F above the maximum

temperature rise shown in Tables 1A and 1B.

When the limit trips, the gas valve is deenergized. Once

the unit cools, the gas valve is reenergized.

ROLLOUT SWITCH — This switch senses any flame or

excessive heat in the main burner compartment and deen-

ergizes the gas valve. If this occurs, the gas heating system

is locked out until the rollout switch is reset manually. Reset

by pressing the button on the rollout switch. See Fig. 39.

When the rollout switch trips,it likely indicates a flue block-

age. Inspect the unit for any obstruction in the flue system,

for holes on the flue box, or for a defective centrifugal switch

or loose combustion blower. See Fig. 63 for proper location

of the rollout capillary.

TROUBLESHOOTING

Economizer —

The economizer control consists of an

electronic control board mounted on the back of the cover

plate of the economizer motor with the adjustments and elec-

trical plugs accessible through the top of thecover. The econo-

mizer control is factory wired to the terminals on the motor.

All potentiometers and adjustments are a part of the control

board.

ECONOMIZER MOTOR CHECKOUT — The motor may

be checked out separately from the control board. See

Table 12 for motor checkout. To check out the motor, apply

24 VAC power to terminals T0 and T2 of the control board.

NOTE: The connections to motor terminals T1 and R must

remain in place.

Table 12 — Economizer Motor Checkout

MOTOR

TEST

PROCEDURE EXPECTED RESULT

AND RESPONSE

A Remove wire connected to

terminal W on the motor.

Motor drives open. If not,

replace the motor.

B Remove wire connected to

terminal B on the motor,

leaving W wire discon-

nected (Test A).

Motor drives closed. If not,

replace the motor.

CONTROL BOARD CHECKOUT — To check out the con-

trol board motor, conduct the following 4 tests.

Test 1:

1. Apply 24 VAC power to terminals T0 and T2 of control

board.

2. Remove mixed air sensor connected between terminals

S1 and S2.

3. Remove outdoor-air enthalpy sensor between terminals

ϩϩ and SO.

4. Refer to Table 13.

Table 13 — Economizer Control Board Checkout,

Test 1

MOTOR

TEST

PROCEDURE EXPECTED RESULT

AND RESPONSE

A Turn minimum position

potentiometer fully

counterclockwise.

Motor drives closed. If not,

check minimum position

jumper between

terminals Z and Y, and

check terminal W and T1

connections to motor.

B Turn minimum position

potentiometer fully

clockwise.

Motor drives open. If not,

check terminal B and R

connections to the motor.

Test 2:

1. Apply 24 VAC power to terminals T0 and T2 of the con-

trol board.

2. Apply 24 v between terminals 1 and T2, and jumper ter-

minal T0 to terminal 1.

3. Remove the mixed-air sensor connected between termi-

nals S1 and S2, and replace it with a 5490-ohm resistor.

4. Remove outdoor-air enthalpy sensor between terminals

ϩϩ and SO, and replace it with a 1.2 kOhm resistor.

5. Turn the minimum position potentiometer fully counter-

clockwise.

6. Refer to Table 14.

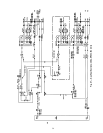

Fig. 62 — Typical Compressor Overtemperature,

High- and Low-Pressure Switch Locations

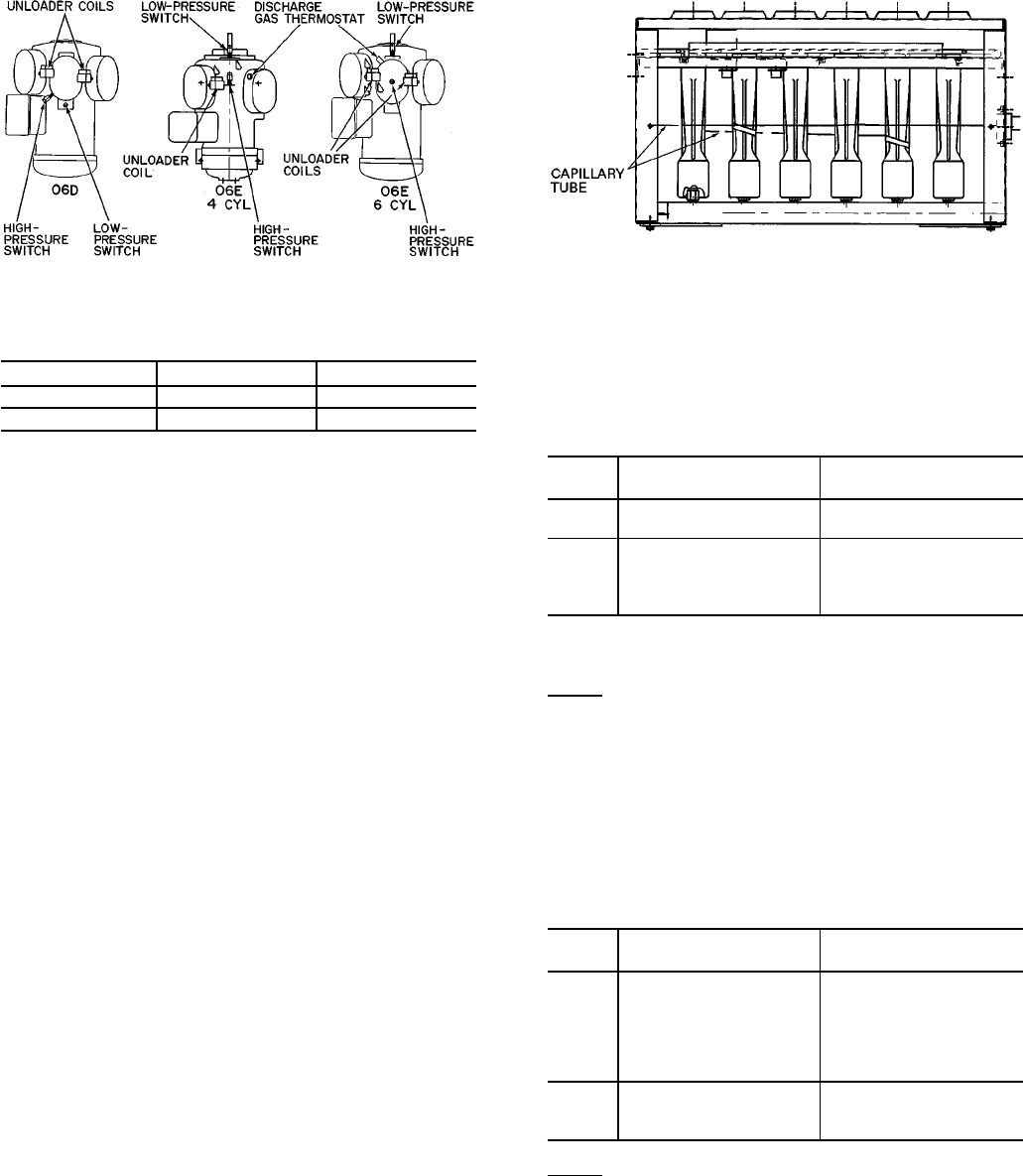

Fig. 63 — Location of Rollout Switch Capillary Tube

52