32

Table 6 — Rnet Wiring Specifications

LEGEND

To wire the SPT sensor to the controller:

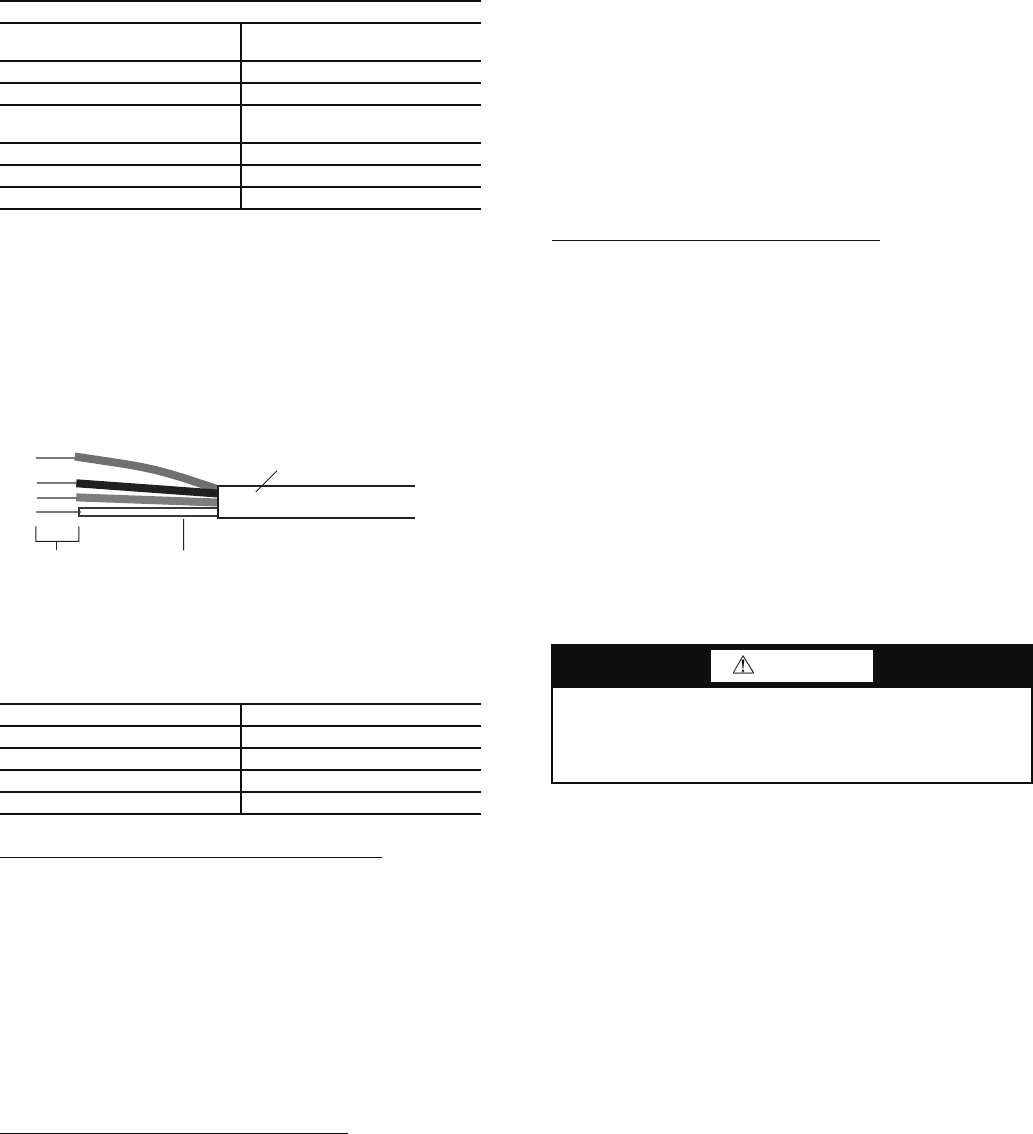

1. Partially cut , then bend and pull off the outer jacket of

the Rnet cable(s), being careful not to nick the inner

insulation.

2. Strip about

1

/

4

in. of the inner insulation from each wire.

See Fig. 34.

3. Wire each terminal on the sensor to the same terminal on

the controller. See Fig. 25-29. Table 7 shows the recom-

mended Rnet wiring scheme.

Table 7 — Rnet Wiring

NOTE: The wire should be connected to the terminal shown.

Wiring a Supply Air Temperature (SAT) Sensor — The

SAT sensor is required for reheat applications.

If the cable used to wire the SAT sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the SAT sensor to the controller:

1. Wire the sensor to the controller. See Fig. 25-29.

2. Verify that the Enable SAT jumper is on.

3. Verify that the Enable SAT and Remote jumper is in the

left position.

Wiring an Indoor Air Quality (IAQ) Sensor

— An IAQ

sensor monitors CO

2

levels. The WSHP Open controller uses

this information to adjust the outside-air dampers to provide

proper ventilation. An IAQ sensor can be wall-mounted or

mounted in a return air duct. (Duct installation requires an aspi-

rator box assembly.)

The sensor has a range of 0 to 2000 ppm and a linear 4 to

20 mA output. This is converted to 1 to 5 vdc by a 250-ohm,

1

/

4

watt, 2% tolerance resistor connected across the zone con-

troller’s IAQ input terminals.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the IAQ sensor to the controller

will be less than 100 ft, an unshielded 22 AWG (American

Wire Gage) cable should be used. If the cable will be greater

than 100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the IAQ sensor to the controller:

1. Wire the sensor to the controller. See Fig. 25-29.

2. Install a field-supplied 250-ohm,

1

/

4

watt, 2% tolerance

resistor across the controller’s RH/IAQ and Gnd

terminals.

3. Verify the the RH/IAQ jumper is set to 0 to 5-vdc.

Wiring a Relative Humidity (RH) Sensor

— The RH sensor

is used for zone humidity control (dehumidification) if the

WSHP unit has a dehumidification device. If not, the sensor

only monitors humidity.

NOTE: Do not use a relative humidity sensor and CO

2

sensor

on the same zone controller if both sensors are powered off the

board. If sensors are externally powered, both sensors may be

used on the same zone controller.

If the cable used to wire the RH sensor to the controller will

be less than 100 ft, an unshielded 22 AWG (American Wire

Gage) cable should be used. If the cable will be greater than

100 ft, a shield 22 AWG cable should be used. The cable

should have a maximum length of 500 ft.

To wire the RH sensor to the controller:

1. Strip the outer jacket from the cable for at least 4 inches.

2. Strip

1

/

4

in. of insulation from each wire.

3. Wire the sensor to the controller.

Step 6 — Install Supply and Return Piping

SUPPLY AND RETURN HOSES — Optional pressure-rated

hose assemblies are available for use with units. Use the fol-

lowing guidelines when installing supply and return hose

assemblies.

1. Install supply and return hoses fitted with swivel-joint

fittings at one end to prevent the hose from twisting.

2. Use male adapters to secure the hose assembly to the unit

and the riser.

3. Do not allow the hose to twist during installation. Twist-

ing may damage the hose wall or the rubber compound.

4. Use pipe joint compound sparingly on the fitting adapt-

ers’ male pipe threads.

5. Prevent sealant from reaching the joint’s flared surfaces.

6. Do not use pipe joint compound when Teflon* thread

tape is pre-applied to hose assemblies or when flared-end

connections are used.

7. Maximum torque that may be applied to brass fittings is

30 ft-lb. When a torque wrench is not used, tighten brass

fittings finger-tight plus one quarter turn.

8. Tighten steel fittings as necessary.

9. Use shut-off/balancing valves, flow indicators, and drain

tees in the supply runout and return at each floor to aid in

loop balancing and servicing.

SUPPLY AND RETURN PIPING — System piping MUST

comply with all applicable codes.

1. Install a drain valve at the base of each supply and return

riser to enable system flushing at start-up and during rou-

tine servicing.

RNET WIRING SPECIFICATIONS

Description

4 conductor, unshielded, CMP,

plenum rated cable

Conductor 18 AWG

Maximum Length 500 ft

Recommended Coloring

Jacket: white

Wiring: black, white, green, red

UL Temperature 32 to 167 F

Voltage 300-vac, power limited

Listing UL: NEC CL2P, or better

AWG — American Wire Gage

CMP — Communications Plenum Cable

NEC — National Electrical Code

UL — Underwriters Laboratories

WIRE TERMINAL

Red +12-v

Black .Rnet

White Rnet+

Green Gnd

Fig. 34 — Rnet Cable Wire

OUTER JACKET

INNER INSULATION

.25 IN.

a50-8443

–

CAUTION

To ensure proper functioning of unit and system, be sure to

connect entering water to upper pipe on right-hand units.

On left-hand units, connect entering water to lower pipe.

Failure to do so could result in equipment damage.

*Teflon is a trademark of E. I. du Pont de Nemours and Company.