26

START-UP

Use the Carrier network communication software to start up

and configure the PremierLink™ controller.

Changes can be made using the ComfortWORKS

®

soft-

ware, ComfortVIEW™ software, or Network Service Tool.

The Network Service Tool is a portable interface device that

allows the user to change system set-up and set points from a

zone sensor or terminal control module. During start-up, the

Carrier software can also be used to verify communication

with PremierLink controller.

NOTE: All set-up and set point configurations are factory-

set and field-adjustable.

For specific operating instructions, refer to the literature

provided with user interface software.

Perform System

Check-Out

1. Check correctness and tightness of all power and

communication connections.

2. At the unit, check fan and system controls for proper

operation.

3. At the unit, check electrical system and connections of

any optional electric heat.

NOTE: If optional electric heat is installed, Heat Type

must be changed to “1” (electric heat) from default of “0”

(gas heat).

4. Check to be sure the area around the unit is clear of

construction dirt and debris.

5. Check that final filters are installed in the unit. Dust and

debris can adversely affect system operation.

6. Verify that the PremierLink controls are properly

connected to the CCN bus.

Initial Operation and Test —

Perform the following

procedure:

1. Apply 24 vac power to the control.

2. Connect the Service Tool to the phone jack service port of

the controller.

3. Using the Service Tool, upload the controller from

address 0, 31 at 9600 baud rate. The address may be set at

this time. Make sure that Service Tool is connected to

only one unit when changing the address.

MEMORY RESET — DIP switch 4 causes a non-volatile

(E-squared) memory reset to factory defaults after the switch

has been moved from position 0 to position 1 and the power

has been restored. To enable the feature again, the switch must

be put back to the 0 position and power must be restored; this

prevents subsequent resets to factory defaults if the switch is

left at position 1.

To cause a reset of the non-volatile memory (to factory

defaults), turn the controller power off if it is on, move the

switch from position 1 to position 0, and then apply power to

the controller for a minimum of 5 seconds. At this point, no

action occurs, but the controller is now ready for the memory

to reset. Remove power to the controller again and move the

switch from position 0 to position 1. This time, when power is

applied, the memory will reset to factory defaults. The control-

ler address will return to bus 0 element 31, indicating that

memory reset occurred.

Install Navigator™ Display Module —

The Navi-

gator is a portable display module that conforms to NEMA 4

specifications for outdoor use in temperatures ranging from

–22 F (–30 C) to 158 F (70 C). The Navigator can be used

to configure and perform service diagnostics on machines

equipped with the PremierLink Controller. See Fig. 31.

The Navigator keypad contains eleven menu LEDs and one

Alarm Status LED, all of which are red. The Navigator is capa-

ble of displaying four 24-character lines of information on a

backlit liquid crystal display. The Navigator has four functional

The unit must be electrically grounded in accordance with

local codes and NEC ANSI/NFPA 70 (American National

Standards Institute/National Fire Protection Association).

4

3

5

2

8

6

7

1

10

11

9

12

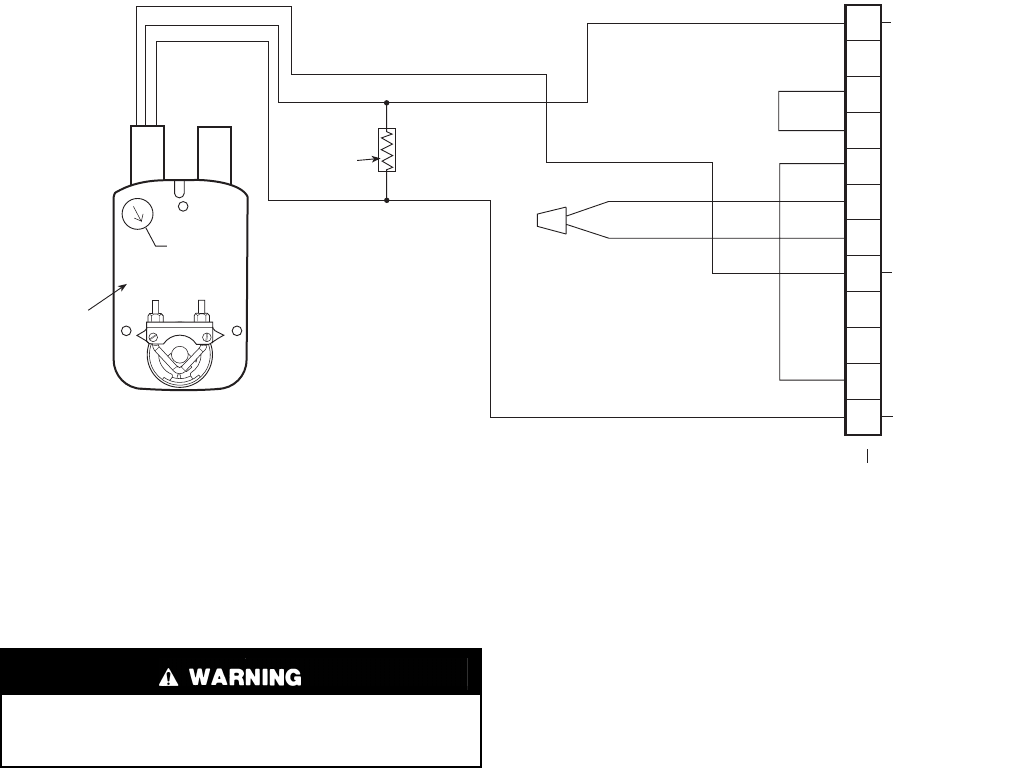

PINK

VIOLET

BLACK

BLUE

YELLOW

NOTE 1

NOTE 2

RUN

500 OHM

RESISTOR

50HJ540573

ACTUATOR

ASSEMBLY

RED

WHITE

ECONOMISER2 PLUG

DIRECT DRIVE

ACTUATOR

4-20 mA TO J9 ON

PREMIERLINK

BOARD

24 VAC

TRANSFORMER

GROUND

WIRES FOR

OAT SENSOR

4-20 mA SIGNAL

NOTES:

1. Switch on actuator must be in run position for economizer to operate.

2. 50HJ540573 actuator consists of the 50HJ540567 actuator and a harness with 500-ohm resistor.

Fig. 30B — PremierLink™ Control Wiring to Belimo-Style Actuator EconoMi$er2 Harness