&-jQ

-

13

a--

4

IN/4

OUT

SWITCH

MODULE

,-

-

m

-

-

-

-f-J

J7-10

,~,.

$$

&

i-

-

___

-

_-a

J7-lf

c,:

*

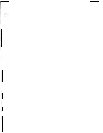

30GN040-210

AND ASSOCIATED MODULAR UNITS

----

1

-El

TB-11

--a-

-0

2

TBI1

30GT225,250,280

FLOTRONIC’” II UNITS

TB

-

Terminal Block

NOTE: The

30GT225,250,280

Flotronic II units require the acces-

sory options module for this feature

Fig. 33

-

Remote Dual Set Point Control

43

7

6

1

------

cl-

CWP

-----

-cl

3

-rB$J

115/23ovv

f

-------_--

__--

4

-t-l

T5-3

30GN040-210

AND ASSOClATED MODULAR UNITS

--v-w

3

El

TE5

WI--

u

4 TE5

30GT225,250,280

FLOTRONIC II UNITS

CWP

-

Chilled Water Pump

TB

-

Terminal Block

NOTE: The maximum load allowed for the chilled water pump circuit

is 125 va sealed, 1250 va inrush at 115 or 230 v

Fig. 34

-

Chilled Water Pump

-43

77

ALARM SHUTOFF

SWITCH

I-

-------a---

-cl

1 TB-3

I

i

L

------2

T8-3

cl

30GN040-210

AND ASSOCIATED MODULAR UNITS

_d--

----

u

2 TB-5

30GT225,250,280

FLOTRONIC II UNITS

TB

-

Terminal Block

NOTE: The maximum load allowed for the alarm circuit is 125 va

sealed, 1250 va inrush at 115 or 230 v

Fig. 35

-

Remote Alarm

73

-43

-78

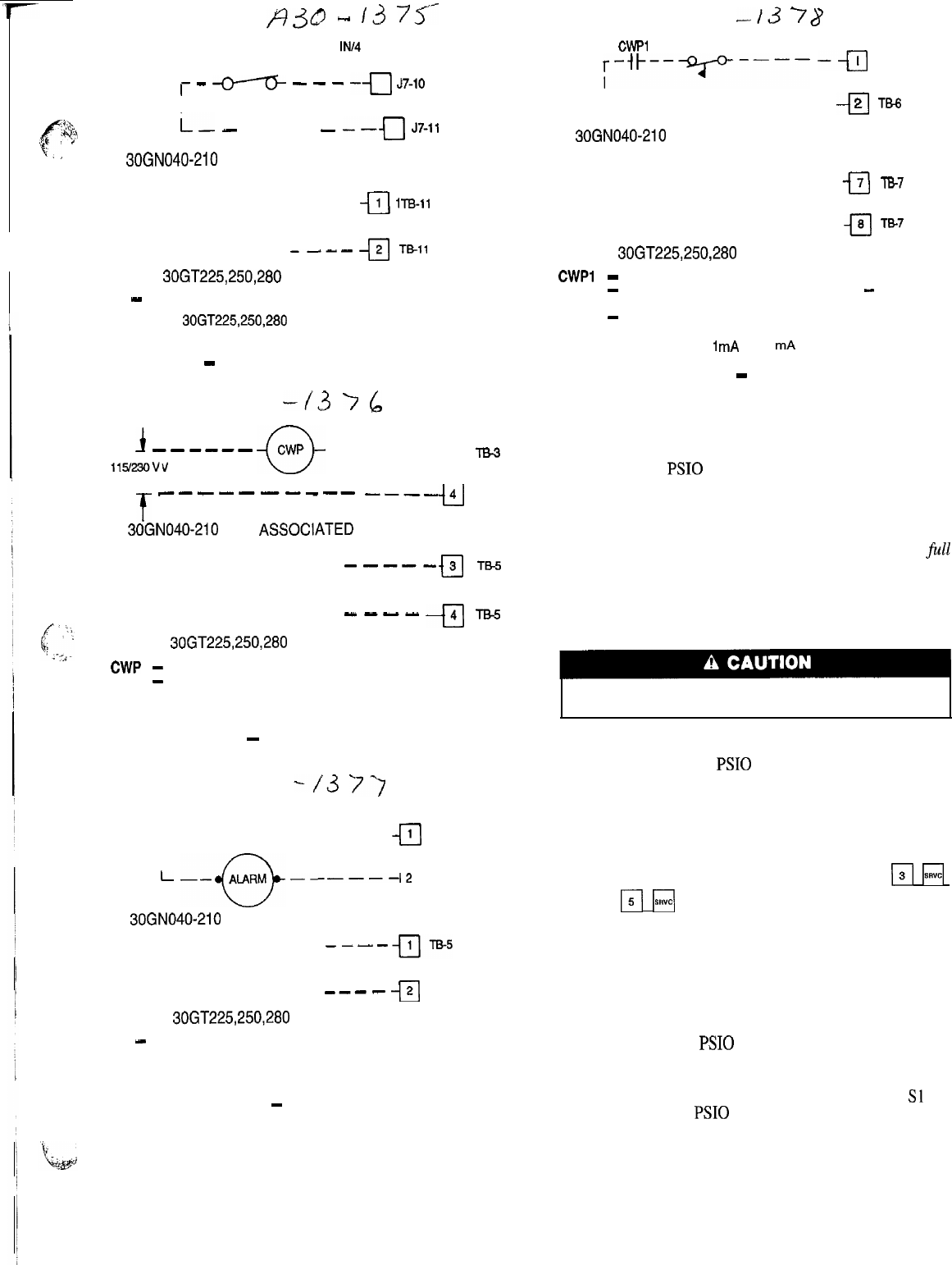

CWPl (CWFS)

;-+--y----

--a

TB-6

I-------

------

-cl

2

TB-6

30GN040-210

AND ASSOCIATED MODULAR UNITS

-----

-El

7

TB-7

-----

u

8 TE7

30GT225,250,280 FLOTRONIC I I UN ITS

CWPI

-

Chilled Water Pump Interlock

CWFS

-

Chilled Water Flow Switch (not required

-

low flow

protection is provided by Flotronic II controls)

TB

-

Terminal Block

NOTE: Contacts must be rated for dry circuit application, capable of

reliably switching a 5 vdc,

1

mA

to 20

mA

load.

Fig. 36

-

Interlocks

REPLACING DEFECTIVE

PROCESSOR MODULE

The replacement part number is printed on a small label

on front of the PSI0 module. The model and serial num-

bers are printed on the unit nameplate located on an exte-

rior corner post. The proper software and unit configuration

data is factory installed by Carrier in the replacement mod-

ule. Therefore, when ordering a replacement processor mod-

ule (PSIO), specify complete replacement part number, full

unit model number, and serial number. If these numbers

are not provided, the replacement module order is config-

ured instead as a generic Flotronic’” 11 replacement mod-

ule. This requires reconfiguration of the module by the

installer.

Electrical shock can cause personal injury, Disconnect

all electrical power before servicing.

Installation

1.

2.

3.

4.

5.

6.

7.

Verify the existing PSI0 module is defective by using

the procedure described in the Control Modules sec-

tion on page 64.

Refer to Start-Up Checklist for Flotronic II Chiller Sys-

tems (completed at time of original start-up) found in

job folder. This information is needed later in this

procedure. If checklist does not exist, fill out the

ri

H

and

Fi

F\

configuration code sections on a new check-

list. Tailor the various options and configurations as

needed for this particular installation.

Check that all power to unit is off. Carefully discon-

nect all wires from defective module by unplugging the

6 connectors. It is not necessary to remove any of the

individual wires from the connectors. Remove the green

ground wire.

Remove defective

PSI0

by removing its mounting screws

with a Phillips screwdriver, and removing the module

from the control box, Save the screws for later use.

Use a small screwdriver to set address switches Sl and

S2 on the new PSI0 module to exactly match the set-

tings on the defective module.

Package the defective module in the carton of the new

module for return to Carrier.

Mount the new module in the unit control box using a

Phillips screwdriver and the screws saved in Step 4 above.