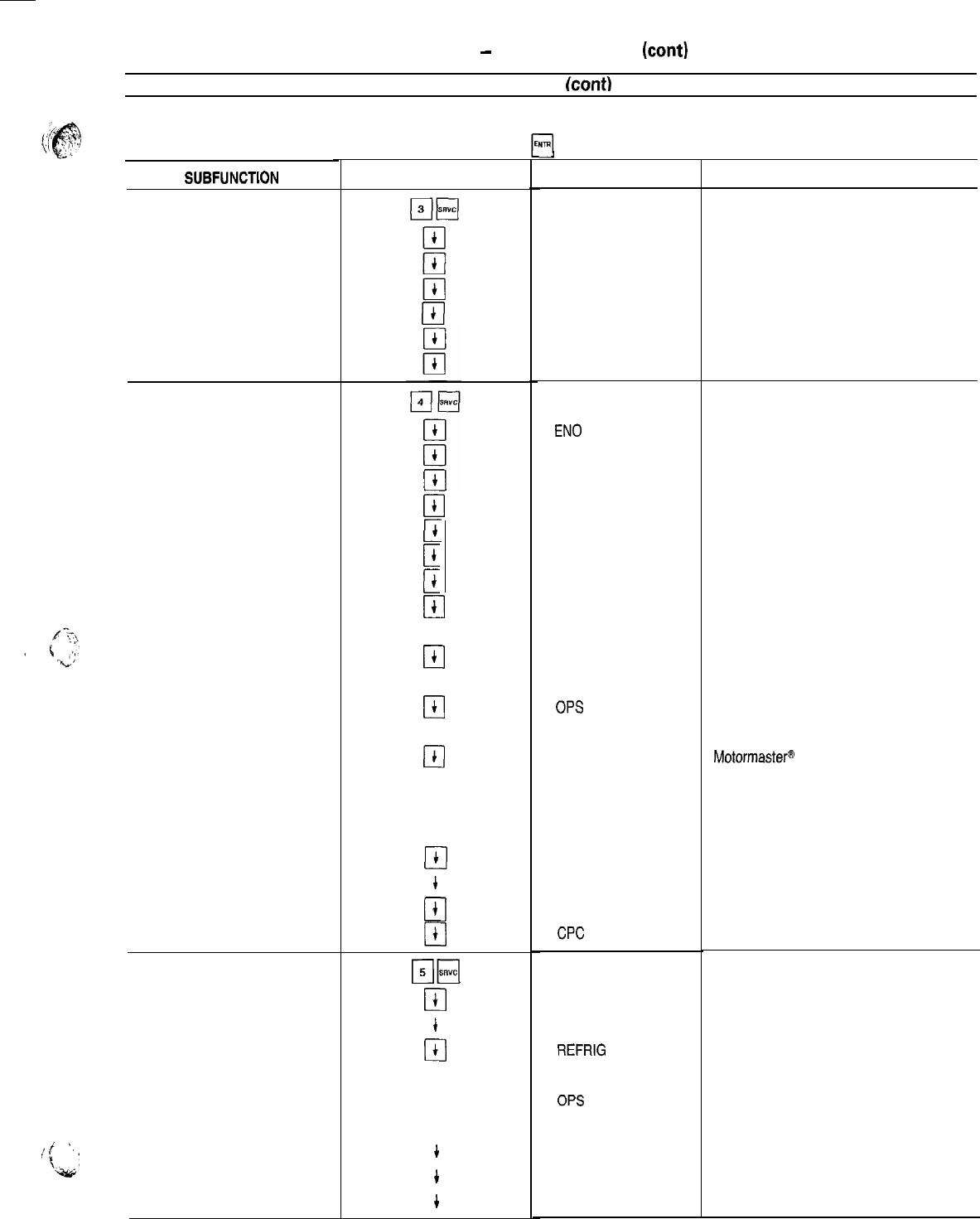

Table 9

-

Keypad Directory (cant)

SERVICE (cord)

The next 3 subfunctions provide the ability to modify configurations Refer to separate Installation, Start-Up, and Service Instructions

supplied with unit for further information on changing configurations.

To change a configuration, enter the new configuration and press

4

while on the correct configuration.

F.-’

SUBFUNCTiON

i

j,

I’

.

Fc,s;B,:

3 FACTORY

CONFIGURATION

4 FIELD

CONFIGURATION

5 SERVICE

CONFIGURATION

KEYPAD ENTRY

Cl

t

Cl

t

c

t

c

t

[I

t

cl

t

cl

t

0

t

q

t

0

t

a

t

Cl

t

cl

t

cl

t

q

t

cl

t

cl

+

Cl

+

Cl

t

p-&q

cl

t

cl

t

Cl

t

cl

t

cl

t

cl

t

cl

+

q

t

cl

t

DISPLAY COMMENT

FACT CFG

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

Factory Configuration Codes

Configuration Code 1

Configuration Code 2

Configuration Code 3

Configuration Code 4

Configuration Code 5

Configuration Code 6

FLD CFG

EN0 X

BUS X

BAUD X

FLUID X

UNITS X

LANG X

NULA X

NULB X

HGB X

SEQT X

SEQF X

OPS

x

HEADM X

MM X

CSPTYP X

CRTYP X

ERTYP X

LSTYP X

RAMP X

LOCK X

CPC

x

Adjustable Field Configuration

CCN Element Address

CCN Bus Number

CCN Baud Rate

Cooler Fluid Select

Display Unit Select

Display Language Select

No Circuit A Unloaders

No. Circuit B Unloaders

Hot Gas Bypass Select

Loading Sequence Select

Lead/Lag Sequence Select

Oil Pressure Switch Select

Head Pressure Control Method

Motormaster@

Select

Cooling Set Point Control Select

Cooling Reset Control Select

External Reset Sensor Select

Demand Limit Control Select

Ramp Load Select

Cooler Pump Interlock Select

Cooler Pump Control Select

SRV CFG

xxxxxxxx

xxxxxxxx

REFRIG X

TDTYP X

OPS

x

LPS x

FANTYP X

SH X

MOP X

Service Configurations

Configuration Code 7

Configuration Code 8

Refrigerant

Pressure Transducer Select

Oil Transducer Set Point

Low Pressure Set Point

Fan Staging Select

EXV Superheat Set Point

EXV MOP Set Point

35