Thermistors

-

All thermistors are identical in their tem-

perature vs. resistance performance. Resistance at various

temperatures are listed in Tables 15 and 16.

LOCATION

-

General location of thermistor sensors are

shown in Fig. 13.

Cooler Leaving Water Thermistor (Tl)

-

Tl is located in

leaving water nozzle. The probe is immersed directly in the

water. All thermistor connections are made through a

%-in.

coupling. See Fig. 15. Actual location is shown in Fig. 13

and 14.

Cooler Entering Water Thermistor (T2)

-

T2 is located in

cooler shell in first baffle space near tube bundle. Ther-

mistor connection is made through a

%-in.

coupling. See

Fig. 15. Actual location is shown in Fig. 13 and 14.

Compressor Suction Gas Temperature Thermistors

(T7

and

T8)

-

T7 and

T8

are located in lead compressor in each

circuit in suction passage between motor and cylinders, above

oil pump. They are well-type thermistors on 040-210 and

associated modular units, or ferrule-type on 225, 250, 280

units. See Fig. 13 and 14.

THERMISTOR REPLACEMENT (Tl , T2, T7, TS) (Com-

pressor and Cooler)

Thermistors are installed directly in fluid or refrigerant

circuit. Relieve all refrigerant pressure using standard

refrigerant practices or drain fluid before removing.

Proceed as follows (see Fig. 15):

To replace sensors

Tl,

T2, T7 (225,250,280), and

T8

(225,250,280)

1. Remove and discard original thermistor and coupling.

IMPORTANT: Do not disassemble new coupling.

Install as received.

I

2. Apply pipe sealant to

‘/a-in.

NPT threads on replace-

ment coupling and install in place of original. Do not

use packing nut to tighten coupling. This damages fer-

rules (see Fig. 15).

3. Insert new thermistor in coupling body to its full depth.

If thermistor bottoms out before full depth is reached,

pull thermistor back out

I/s

in, before tightening packing

nut. Hand tighten packing nut to position ferrules, then

finish tightening

19’4

turns with a suitable tool. Ferrules

are now attached to thermistor which can be withdrawn

from coupling for unit servicing.

To replace thermistors T7 and T8 (040-210 and associated

modular units):

Add a small amount of thermal conductive grease to ther-

mistor well. Thermistors are friction-fit thermistors, which

must be slipped into receiver located in the compressor pump

end.

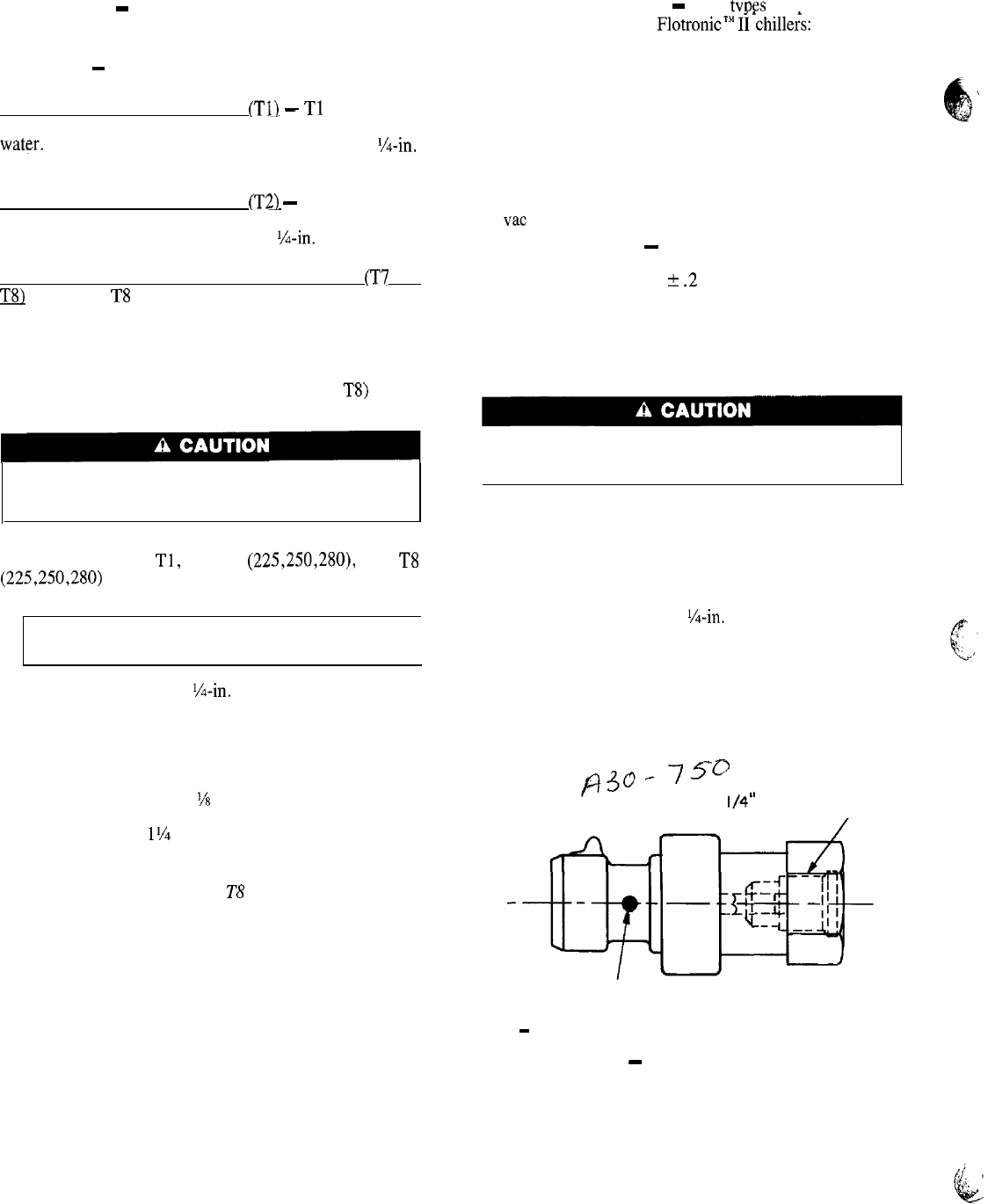

Pressure Transducers

-

TWO

tvpes

of pressure trans-

ducers are used on 30G Flotronic’”

Ii*chille&:

a low pres-

sure transducer and a high pressure transducer. The low

pressure transducer is identified by a white dot on the body

of the transducer, and the high pressure transducer by a red

dot. See Fig. 16.

Three pressure transducers are mounted on each lead com-

pressor: 2 low-pressure transducers to monitor compressor

suction pressure and oil pressure, and a high-pressure trans-

ducer to monitor compressor discharge pressure (see

Fig. 17 for exact locations on compressor). Each transducer

is supplied with 5 vdc power from a rectifier which changes

24 vat to 5 vdc.

TROUBLESHOOTING

-

If transducer is suspected of be-

ing faulty, first check supply voltage to transducer. Supply

voltage should be 5 vdc + .2 v. If supply voltage is cor-

rect, compare pressure reading displayed on keypad and dis-

play module against pressure shown on a calibrated pres-

sure gage. If the 2 pressure readings are not reasonably close,

replace pressure transducer.

TRANSDUCER REPLACEMENT

Transducers are installed directly in the refrigerant cir-

r

cuit. Relieve all refrigerant pressure using standard re-

frigeration practices before removing.

1. Relieve refrigerant pressure using standard refrigeration

practices.

2. Disconnect transducer wiring at transducer by pulling

up on locking tab while pulling weather-tight connection

pfug from end of transducer. Do not pull on trans-

ducer wires.

3. Unscrew transducer from

!&in.

male flare fitting. When

installing new pressure transducer, do not use thread

sealer. Thread sealer can plug transducer and render it

inoperative.

4. Insert weathertight wiring plug into end of transducer

until locking tab snaps in place.

5. Check for refrigerant leaks.

-75”

l/4”

SAE FEMALE FLARE

WHITE DOT-LOW PRESSURE TRANSDUCER

RED DOT -HIGH PRESSURE TRANSDUCER

SAE

-

Society of Automotive Engineers

Fig. 16

-

Pressure Transducer

60