Table 12

-

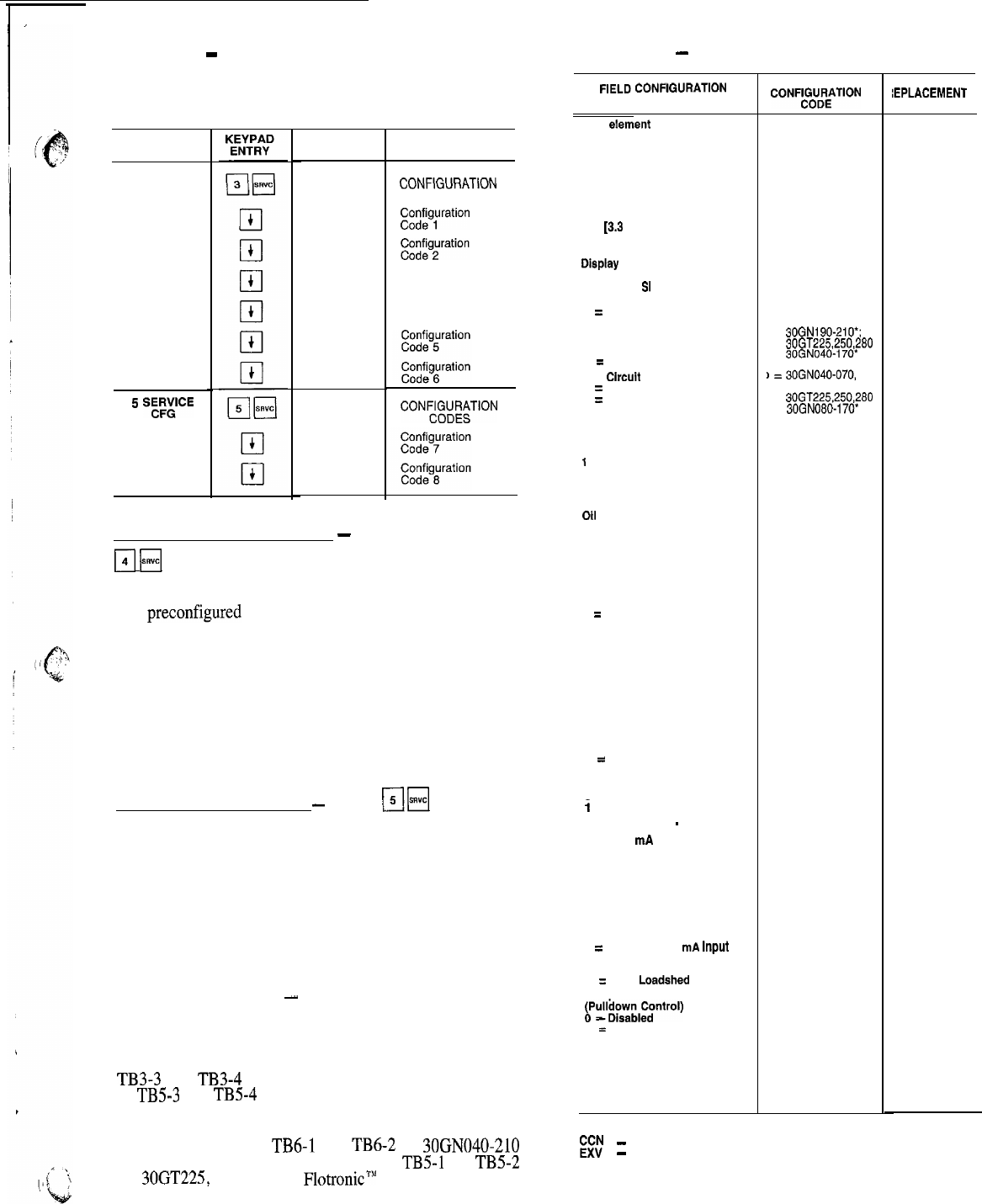

Factory Configuration Keystrokes

To change a configuration enter the new configuration

and press

q

while on the correct configuration.

SUB-

FUNCTION

3 FACTORY

CFG

5

%FE

DISPLAY COMMENTS

FACT CFG

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

xxxxxxxx

FACTORY

CONFlGURATlON

CODES

CJz;;g;ration

Configuration

Code 3

Configuration

Code 4

SRV CFG

SERVICE

CONW;;T’ON

xxxxxxxx

xxxxxxxx

Adiustable Field Configurations

-

After logging on, press

ri

H

to enter subfunction. The subfunction allows oper-

ation of the chiller to be customized to meet the particular

needs of the application. The chiller comes from the fac-

tory

preconfigured

to meet the needs of most applications.

Each item should be checked to determine which configu-

ration alternative best meets the needs of a particular appli-

cation. See Table 13 for factory loaded configuration codes

and alternative configurations.

If processor module is replaced, the replacement module

is preloaded with factory default configuration codes. Each

configuration code must be checked and, if necessary, re-

configured to meet needs of the application. See

Table 13 for pre-loaded service replacement configuration

codes.

Service Configuration Codes

-

Press

r;lH

to enter the

service configuration subfunction. The first 2 items under

this subfunction are 2 groups (8 digits each) of configura-

tion codes that are downloaded at the factory. If processor

module is replaced in the field, the 2 groups of configura-

tion codes must be entered through the keypad and display

module. The 2 groups of configuration codes (groups 7 and

8) that apply to the unit being serviced can be found on a

label diagram inside the control box cover. See Table 12

for keystroke information to enter configuration codes 7

and 8.

SCHEDULE FUNCTION

-

This function provides a means

to automatically switch chiller from an occupied mode to

an unoccupied mode, When using schedule function, chilled

water pump relay must be used to switch chilled water pump

on and off. Connections for chilled water pump relay are:

TB3-3 and TB3-4 (040-210 and associated modular units)

or TB5-3 and TB5-4 (225, 250, and 280 units). The chilled

water pump relay starts chilled water pump but compres-

sors do not run until remote chilled water pump interlock

contacts are between TB6-1 and TB4-2 on 30GN040-210

and associated modular units, or between TB5-1 and TB5-2

on 3OGT225, 250, and 280 Flotronic” units are closed and

leaving chilled water temperature is above set point. If a

remote chilled water pump interlock is not used, the first

compressor starts (upon a call for cooling) approximately

one minute after chilled water pump is turned on.

Table 13

-

Adjustable Field Configurations

FIELD

CONFlGURATlON

ITEM AND CODES

CCN element address

(Entered by CCN Technician)

CCN Bus Number

(Entered by CCN Technician)

CCN Baud Rate

(Entered by CCN Technician)

Cooler Fluid Select

1 = Water (38 to 70 F

[3.3 to 21 C] Set Point)

2 = Medium Brine (15 to 70 F

f-9 to 21 C] Set Point)

Display Unit Select

0 = English

1 = Metric

SI

Display Language Select

1

=

English

No. Circuit A Unloaders

0 = No Unloaders

1 = One Unloader

2

=

Two Unloaders

No. Circuit B Unloaders

0

=

No Unloaders

1

=

One Unloader

2 = Two Unloaders

Hot Gas Bypass Select

0 = No Valve

Loading Sequence Select

1

= Equal Circuit Loading

2 = Staged Circuit Loading

Lead/Lag Sequence Select

1 = Automatic

Oil Pressure Switch Select

0 = Not Used

1 = Air Cooled

Head Pressure Control Type

0 = Not Used

1 = Air Cooled

Head Pressure Control Method

1 = EXV Controlled

2

=

Set Point Control for

Both Circuits

3 = Set Point Control for

Circuit A; EXV Control

for Circuit B

4 = Set Point Control for

Circuit B; EXV Control

for Circuit A

Cooling Set Point

Control Select

0 = Single Set Point Control

1 = External Switch

Controlled Set Point

2

=

Clock Controlled

Set Point

Cooling Reset

0 = No Reset

Control

Select

i

= Return Fluid Reset

2 = External Temperature

Reset

-

3 = 4-20 mA Controlled

Reset

External Reset Sensor Select

0 = Thermistor Connected to

Options Module

1 = Obtained Through CCN

Demand Limit Control Select

0 = No Demand Limiting

1 = Two External Switch Input

2 = External 4-20

mA

Input

3 = CCN Load Limiting

(Multi-Unit)

4

=

CCN Loadshed Interface

Ramo Load Select

~P@os~dol~ntrol)

1

=

Enabled

Cooler Pump Interlock Select

0 = No Interlock

1 = With Interlock

Cooler Pump Control Select

0 = Not Controlled

1 = ON/OFF Controlled

FACTORY

CONFF$ikTlON

001 001

000 000

9600

9600

= Standard Models

1

0

1

0

0

0

1

1

0

0

1

0

0

0

0

0

0

0

I = Brine Models

0

I =

30GN190-HO*;

30GT225,250,280

=

30GN040-170*

)

=

30GN040-070,

190-210';

30GT225,250,280

=

30GN080-170*

0

0

0

0

0

0

LEGEND

EE

-

Carrier Comfort Network

-

Electronic Expansion Valve

*And associated modular units

SERVICE

IEPLACEMENT

CODE

45