NOTE: The gas manifold is equipped with a plug located ap-

proximately 5 in. down from the gas valve which may also be

used to connect the manometer.

4. Turn on gas to unit.

5. Remove cover screw over regulator adjustment screw

on gas valve. See Fig. 31.

6. Adjust regulator adjustment screw for a manifold pres-

sure reading of 3.5 in. wg (high fire on two-stage units).

Turn adjusting screw clockwise to increase manifold pres-

sure, or turn adjusting screw counterclockwise to

decrease manifold pressure.

7. Replace cover screw.

8. Turn off gas to unit.

9. Remove manometer from pressure tap.

10. Replace pipe plug on gas valve or manifold.

11. Turn on gas to unit, and check for leaks.

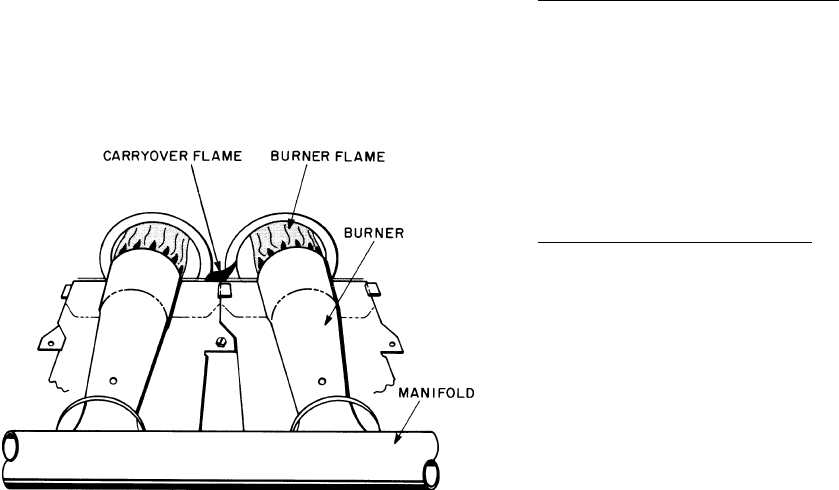

F. Check Burner Flame and Ignition

Observe the unit heating operation. Watch the burner flames

through the access door to see if they are light blue and soft

in appearance and if the flames are approximately the same

for each burner. See Fig. 32.

Main burners are factory set and should require no

adjustment.

To check ignition of main burners and heating controls, move

thermostat set point above room temperature and verify that

the burners light and evaporator fan is energized. Check heat-

ing effect, then lower the thermostat setting below the room

temperature and verify that the burners and evaporator fan

turn off.

Refer to Table 6 for the correct orifice to use at high

altitudes.

G. Airflow and Temperature Rise

The heating section of each side of unit is designed and

approved for heating operation within the temperature rise

range stamped on the unit rating plate. Temperature rise range

is also found in Table 1.

The heating operation airflow must produce a temperature

rise that falls within the approved range.

Refer to Care and Maintenance section on page 28 to adjust

heating airflow when required.

H. Safety Check of Limit Control

Limit control is located on the deck next to the evaporator

fan. The control shuts off the gas supply and energizes

the evaporator-fan motor and inducer motor if the unit

overheats.

The recommended method of checking this limit control is to

gradually block off the return air after the unit has been

operating for a period of at least 5 minutes. As soon as the

limit control functions, the return-air opening should be un-

blocked to permit normal air circulation. By using this method

to check the limit control, it can be established that the limit

is functioning properly and the unit will ‘‘fail-safe’’ if there is

a restricted circulating air supply or motor failure. If the limit

control does not function during this test, the cause must be

determined and corrected.

I. Heating Sequence of Operation

Heating, Units Without Economizer

When the thermostat calls for heating, terminal W1 is ener-

gized. In order to prevent thermostat short-cycling, the unit

is locked into the Heating mode for at least 1 minute when

W1 is energized. The induced-draft motor is energized and

burner ignition sequence begins. The indoor (evaporator) fan

motor (IFM) is energized 45 seconds after a flame is ignited.

When additional heat is needed, W2 is energized and the high-

fire solenoid on the main gas valve (MGV) is energized. When

the thermostat is satisfied and W1 is deenergized, the IFM

stops after a 45-second time-off delay.

Heating, Units With Economizer

When the thermostat calls for heating, terminal W1 is ener-

gized. In order to prevent thermostat short-cycling, the unit

is locked into the Heating mode for at least 1 minute when

W1 is energized. The induced-draft motor is energized and

the burner ignition sequence begins. The indoor (evaporator)

fan motor (IFM) is energized 45 seconds after a flame is

ignited and the damper moves to the minimum position. If

the two-position damper is used, the outdoor-air damper opens

to the minimum position whenever the evaporator-fan runs.

When additional heat is needed, W2 is energized and the high-

fire solenoid on the main gas valve (MGV) is energized. When

the thermostat is satisfied and W1 is energized, the IFM stops

after a 45-second time-off delay. The economizer damper then

moves to the fully-closed position. When using continuous fan,

the damper will remain in the minimum position.

J. Limit Switches

Heating limit switch (LS) deenergizes the gas valve and the

Integrated Gas Unit Controller (IGC) if the leaving-air tem-

perature exceeds the maximum allowable temperature.

Normally-closed limit switch completes a circuit to the gas

valve. Should the leaving-air temperature rise above the

maximum allowable temperature, the limit switch opens,

instantly closing the gas valve and stopping gas flow to the

burners. The inducer motor and the evaporator motor are en-

ergized to cool heat exchanger.

When the air temperature at the limit switch drops to the

low-temperature setting of the limit switch, the switch closes

and completes the gas valve circuit. The electric-spark igni-

tion system cycles and the unit returns to normal heating

operation.

K. Rollout Switch

Rollout switch (RS) is a temperature-actuated automatic re-

set switch connected in series with heating limit switch. The

function of the switch is to close the main gas valve in the

Fig. 32 — Monoport Burners

—20—