Internet Version for Reference Only

Bradford White

Page 36

Copper Brute II

Page 37

8.6 Troubleshooting Copper Brute II

Controls

The Copper Brute II series consists of two 2-

stage models (500 and 750), one 3-stage model (1000),

and four 4-stage models (1250 to 2000). The 2-stage

models have one ignition module, and the 3- and

4-stage models have two ignition modules capable of

independent operation.

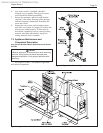

A diagnostic panel, that includes test points, as

well as diagnostic lights, is provided in the control

module. It is located on the right side of the module,

behind the display. To access, remove the retaining

screws from the display cover panel and remove

it. Grasp the control module at its base and pull it

outward. Ladder diagrams are shown in Figures 18

through 20. Voltage test points on the diagnostic

panel are indicated by solid circles connected by short

diagonal lines.

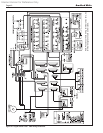

Figure 18 shows the diagram for the 2-stage

models 500 and 750. These have one blower and one

ignition module. The blower is energized directly

through the “inducer” terminals F1 and F2 of the

(Fenwal) ignition module. The 24V power to the 2

nd

stage gas valve is routed through the 1

st

stage VALVE

terminal, so that stage 2 cannot re unless the stage 1

gas valve is open. The 750 differs from the 500 only

in that the 750 has two gas trains in stage 1, while the

500 has only one.

The ladder diagram for the model 1000 is shown

in Figure 19. Ignition module #1 handles stages 1 and

2, and ignition module #2 handles stage 3. The single

blower is energized directly through the “inducer”

terminals of either ignition module. The 24V power to

the T’STAT terminal of both ignition modules is routed

through the safety interlocks.

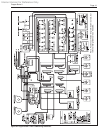

The ladder diagram for models 1250 to 2000 is

shown in Figure 20. These 4-stage models have two

ignition modules, each with its own blower, and each

controlling 2 stages. The blowers are energized by

the ignition modules indirectly via switching relays.

When either ignition module receives a call for heat, it

switches its blower to high speed and the blower of the

idle ignition module to low speed.

The wiring schematics for the Copper Brute II

500 – 1000 are shown in Figure 21, and the schematics

for the 1250 to 2000 are shown in Figure 22. All 24V

wiring is routed through the diagnostic PC board.

Wiring harnesses connect between the diagnostic PC

board and the control components, indicator board,

or eld wiring terminal strip. The diagnostic board

contains LEDs that indicate open status of the safety

interlocks, and quick-connect terminals that provide

tests points for checking voltage/continuity at various

points in the control circuit. Line-voltage connections

are routed via the line-voltage terminal buss.

Certain control elements that may need to be

re-wired in the eld are connected via the eld wiring

terminal strip rather than to the diagnostic PC board.

These include the low-water cutoff (LWCO), water

ow switch, and inlet/outlet water temperature sensors.