Internet Version for Reference Only

Bradford White

Page 28

Copper Brute II

Page 29

signal to these terminals. The control energizes the

heater pump (if equipped), energizes the Pmp-Pmp

terminals, and turns on the heater pump segment in the

display. The control also turns on stage 1 of the heater.

Section 5.3 contains important information about

external staging controls and building automation

systems. Other wiring methods may be unsafe. The

wiring in Section 5.3 of this manual must be used.

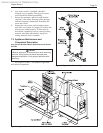

6.3.11 Limit Controls

In addition to the temperature control, Copper

Brute II appliances are tted with a manual reset

high limit and an automatic reset high limit. These

are located near the rear of the cabinet on the right

side, behind the slide out drawer (see Figure 17).

Both controls should be set at least 25°F higher than

the target temperature to avoid short cycling. To set

these controls, remove the control panel cover and

pull the control panel out to gain access. Appliances

with reversed heat exchangers have the limit controls

relocated to the left side of the appliance. The left

access door must be removed to gain access to the

limit controls on these appliances.

6.3.12 Advanced Programming Mode

Advanced programming mode allows the

installer to set the temperature control for proportional

staging. In advanced programming mode, the

interstage differential, interstage delay, interstage on

and off delay, and minimum time on and off are all set

manually.

NOTE: Advanced programming mode is rarely

required. It is intended for advanced installers,

and only when the application demands such

programming.

To enter advanced programming mode, remove

the bezel on the temperature control by pulling out at

the bottom. Remove the small Phillips head screw to

access the dip switch. The dip switch is mounted on a

circuit board.

Locate the letter “A” on the circuit board and

slide the corresponding dip switch toward the letter

“A”. The default setting of this dip switch is toward

the “OFF” lettering on the circuit board.

6.4 Operating the Burner and Set Up

6.4.1 Set Up for 0 to 2500 Feet Altitude

The Copper Brute II appliance utilizes a modular

design to achieve its stage-ring. The setup must be

checked before the unit is put in operation. Problems

such as failure to start, rough ignition, strong exhaust

odors, etc. can be due to improper setup. Damage to

the Copper Brute II resulting from improper setup is

not covered by the limited warranty.

1. Using this manual, make sure the installation

is complete and fully in compliance with the

instructions.

2. Determine that the appliance and system are

lled with water and all air has been bled from

both. Open all valves.

3. Observe all warnings on the Operating

Instructions label and turn on gas and electrical

power to appliance.

4. Switch on the heater power switch located on the

right side of the unit.

5. The heater will enter the start sequence, as long

as the unit is being called for heat. The blower

and pump come on for pre-purge, then the ignitor

warm-up sequence starts and after the ignitor

warm-up is complete and all safety devices are

veried, the gas valves open. If ignition doesn’t

occur, check that there is proper gas supply.

Wait 5 minutes and start the unit again. During

initial start up, air in the gas line may cause the

heater to "lock out" during the rst few trials

for ignition. Depending on the ignition modules

installed, the manual reset button on the ignition

modules may need to be depressed to restart the

heater.

6. When the unit is running, the supply gas pressure

must be checked. Inlet gas pressure must not

exceed 13" W.C. (3.2kPa). The minimum inlet

gas pressure is 5" W.C. (1.2kPa).

7. Once the inlet gas pressure is veried, the

outlet gas pressure from each valve (manifold

gas pressure) must be checked, and adjusted, if

necessary. The manifold gas pressure must be

2.5" W.C. (0.62kPa).

8. Complete the setup by checking the CO

2

at the

outlet of the unit. The CO

2

should be 8% for

natural gas, or 9.2% for propane.

9. After placing the heater in operation, the

Burner Safety Shutoff Device must be tested.

To test:

(a) Close gas shutoff valve with burner

operating.

(b) The ame will go out and blower will

continue to run for the post purge cycle.

One additional attempt to light will follow.

Ignition will not occur as the gas is off. The

ignition control will lockout, and will have

to be reset before the unit will operate.

(c) Open gas shutoff valve. Restart the

appliance. The ignition sequence will

start again and the burner will start. The

appliance will return to its previous mode

of operation.

NOTE: Models 1000 - 2000 have two ignition controls

and two ignitors, which work independently of one

another. If the ignition control for stages 1 and 2 fails

to properly light the main burners for those stages, the

second ignition control will still be active, and will be

able to energize stages 3 and 4. This, of course, will

only occur if all other safety devices conrm that the

unit will run in a safe condition.