Internet Version for Reference Only

Bradford White

Page 24

Copper Brute II

Page 25

If the heater is not a pump mounted model, a

24VAC pump contactor may be connected to the

“PMP” terminals to control a eld installed pump.

Program the temperature control to use “Mode

2.” The AUTO/MAN switch must be in the AUTO

position in this mode.

Mode 4: Hydronic outdoor reset system

without primary / secondary piping.

Bradford White strongly suggests the use of

primary secondary piping with the Copper Brute II

heater. This piping style best ensures that the Copper

Brute II will have proper water ow. However, non-

primary secondary methods can be used successfully,

so this section has been included.

Install the outdoor reset sensor, Bradford White

part number R2014000, and connect the leads to the

“OD S” and “S C2” terminals.

You must provide an indication of the system’s

heat demand by removing the jumper across the

“ComD” and “HtD” terminals on the eld wiring

panel and connecting a zone valve or zone pump end

switch, thermostat, aquastat or other contact closure to

these terminals. If the “ComD” and “HtD” terminals

are left jumpered, the control will always see a heat

demand and remain in “Dem” mode, with the boiler

pump running continuously. See Section 5.2 for more

information.

Reset Override: An additional thermostat or aquastat

may be connected to the “Set D” and “Com D”

terminals. A call for heat from either of these controls

will start the heater’s pump and cause the heater to re.

If the heater is not a pump mounted model, a

24VAC pump contactor may be connected to the

“PMP” terminals to control a eld installed pump.

Program the temperature control to use “Mode

4.” The AUTO/MAN switch must be in the AUTO

position in this mode.

Mode 5: Primary secondary piping with

outdoor reset.

Install the outdoor reset sensor, Bradford White

part number R2014000, and connect the leads to

the “OD S” and “S C2” terminals. Install a “supply

sensor” in the primary loop using the Bradford White

part number R2014800 sensor (included with every

heater). Connect the sensor to the “S C2” and “SUP S”

terminals.

You must provide an indication of the system’s

heat demand by removing the jumper across the

“ComD” and “HtD” terminals on the eld wiring

panel and connecting a zone valve or zone pump end

switch, thermostat, aquastat or other contact closure to

these terminals. If the “ComD” and “HtD” terminals

are left jumpered, the control will always see a heat

demand and remain in “Dem” mode, with the heater

pump running continuously. See Section 5.2 for more

information.

A secondary aquastat, such as for a separate heat

exchanger for DHW, can be connected to the “Set D”

and “Com D” terminals. A call for heat from these

controls will start the heater pump and cause the heater

to re.

If the heater is not a pump mounted model, a

24VAC pump contactor may be connected to the

“PMP” terminals to control a eld installed pump.

Program the temperature control to use “Mode

5.” The AUTO/MAN switch must be in the AUTO

position in this mode.

Mode 6: Heater with external staging

control (multiple boiler control,

building automation system, energy

management system, etc.)

Leave the jumper installed between “Ht D” and

“Com D” terminals. There are terminals on the eld

wiring panel that must be wired per the instructions

in section 5.3 of this manual. Other wiring methods

may be unsafe. The wiring in section 5.3 of this

manual must be used.

The AUTO/MAN switch is located on the circuit

board in the slide-out control panel on the front of the

heater. This switch is placed in the manual position

(MAN) when an external control is controlling the

heater stages.

Program the temperature control to use Mode 6.

Mode 6 tells the heater control that an external staging

control is being used.

6.3 Advanced Topics

For most installations, section 6.2 provides all

the information required to set up the Copper Brute II

heater, and this section should be skipped. Continue

setup in section 6.4.

This section provides denitions of the

programming parameters, advanced programming

topics, and other information that may be of interest.

Advanced programming mode allows the

installer to set the temperature control for proportional

staging. In advanced programming mode, the

interstage differential, interstage delay, interstage on

and off delay, and minimum time on and off are all set

manually.

NOTE: Advanced programming mode is not required

in most applications, and is intended for advanced

installers only.

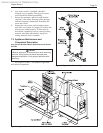

To enter advanced programming mode, remove

the bezel on the temperature control by pulling out at

the bottom. Remove the small Phillips head screw to

access the dip switch. The dip switch is mounted on

a circuit board. Locate the letter “A” on the circuit

board and slide the corresponding dip switch toward

the letter “A”. The default setting of this dip switch is

toward the “OFF” lettering on the circuit board.