Internet Version for Reference Only

Bradford White

Page 32

Copper Brute II

Page 33

The gas and electric controls on the appliance

are engineered for long life and dependable operation,

but the safety of the equipment depends on their

proper functioning. It is strongly recommended that

a qualied service technician inspect the basic items

listed below every year.

a. Ignition controls

b. Ignitors

c. Water temperature control

d. Automatic gas valve

e. Pressure switches

f. Blowers

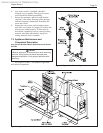

7.2.1 Burners

Close main manual gas valve before proceeding.

Checking the burners for debris - Remove the ignitor

inspection panels(s) and ignitor(s) and inspect the

burners through the ignitor hole(s) using a ashlight

to illuminate. If there is any indication of debris on

the burners that are visible, all the burners will need

to be inspected more thoroughly. Remove the screws

from around the front of the air box (large panel from

which the ignitor inspection panel(s) were removed),

and remove the large panel. Remove the gas manifold

assemblies and the burner panels. Inspect the burners.

Clean burners, if necessary, by blowing compressed

air from the outside of the burners into the center

of the burner. A dirty burner may be an indication

of improper combustion or dirty combustion air.

Determine the cause, and correct. Replace the burners

in the reverse order

7.2.2 Filter

The lter used in the heater is washable with an

83% arrestance. Since the lter is washable, it will

only need replacement when unwashable, deteriorated

or damaged. If lter replacement is needed, it should

only be replaced with a factory part. Inspect the air

lter. If there is debris on the air lter, remove it from

the lter box, and wash it with mild soap and water.

Ensure that the lter is completely dry before re-

installing, in reverse order.

7.2.3 Gas Valves

The gas valves are designed to operate with

supply pressures of 4-13 inches w.c. (1.0 to 3.2 kPa).

To remove a valve, shut off 120-volt power and

the manual gas shutoff valve. Remove the top front

panel from the unit. Disconnect the wires to the valve.

Disengage the anges before and after the valve,

and remove the valve. Re-install in reverse order,

ensuring that the gasket o-rings are placed properly

in the grooves on the anges. Turn on manual gas

shutoff valve and 120 volt power and check appliance

operation and tightness of gas valve connections.

7.2.4 Manual Reset High Limit Control

The high limit switch is manual reset switch

with an adjustable set point, up to 200°F (93°C). To

replace the switch, shut off the 120-volt power to the

appliance. Remove the cover from the switch to access

the mounting screws. Remove the screws, and pull

the switch off the control panel. Remove the capillary

and bulb from the thermal well located in the header.

Replace in reverse order.

7.2.5 Automatic Reset High Limit Control

An automatic reset high limit is used in addition

to the manual reset high limit. The high limit switch

has an adjustable set point, up to 200°F (93°C). To

replace the switch, shut off the 120-volt power to the

appliance. Remove the cover from the switch to access

the mounting screws. Remove the screws, and pull

the switch off the control panel. Remove the capillary

and bulb from the thermal well located in the header.

Replace in reverse order.

7.2.6 Temperature Control

The temperature control is a Bradford White

LHSC. To replace the control, shut off the 120-volt

power to the appliance. Remove the cover from the

control panel, and remove the mounting screws to

remove the controller. Replace in reverse order.

7.2.7 Ignition Controls

The ignition controls ensure the proved

interrupted-type ignition system. They control the

hot surface ignitors and prove that the ame signal

is appropriate for powering the gas valves. It also

controls the blower’s pre-purge and post-purge.

Copper Brute II models 500 and 750 have one ignition

control. Models 1000 to 2000 have two ignition

controls. On models 1000, one ignition control

controls stages 1 and 2, and the second ignition control

controls stage 3. On models 1250-2000, one ignition

control is for stages 1 and 2, and the other is for stages

3 and 4.

To replace a control, shut off the 120-volt power

to the appliance. Remove the cover from the control

panel. Remove the electrical connectors from the

ignition control. Take out the controller’s mounting

screws, and pull the controller out. Replace in reverse

order.

7.2.8 Ignitors

The ignitors used are 120v “Hot Surface” type.

They are energized whenever there is a call for heat

and switched off when ignition is established and the

ame has been sensed. Copper Brute II models 500

and 750 have one ignitor. Models 1000 to 2000 have

two ignitors. To replace the ignitor, shut off the 120-

volt power to the appliance, remove the ignitor access

panel, disconnect the Molex connector, remove the

two mounting screws on the ignitor ange, and pull the