Internet Version for Reference Only

Bradford White

Page 18

Copper Brute II

Page 19

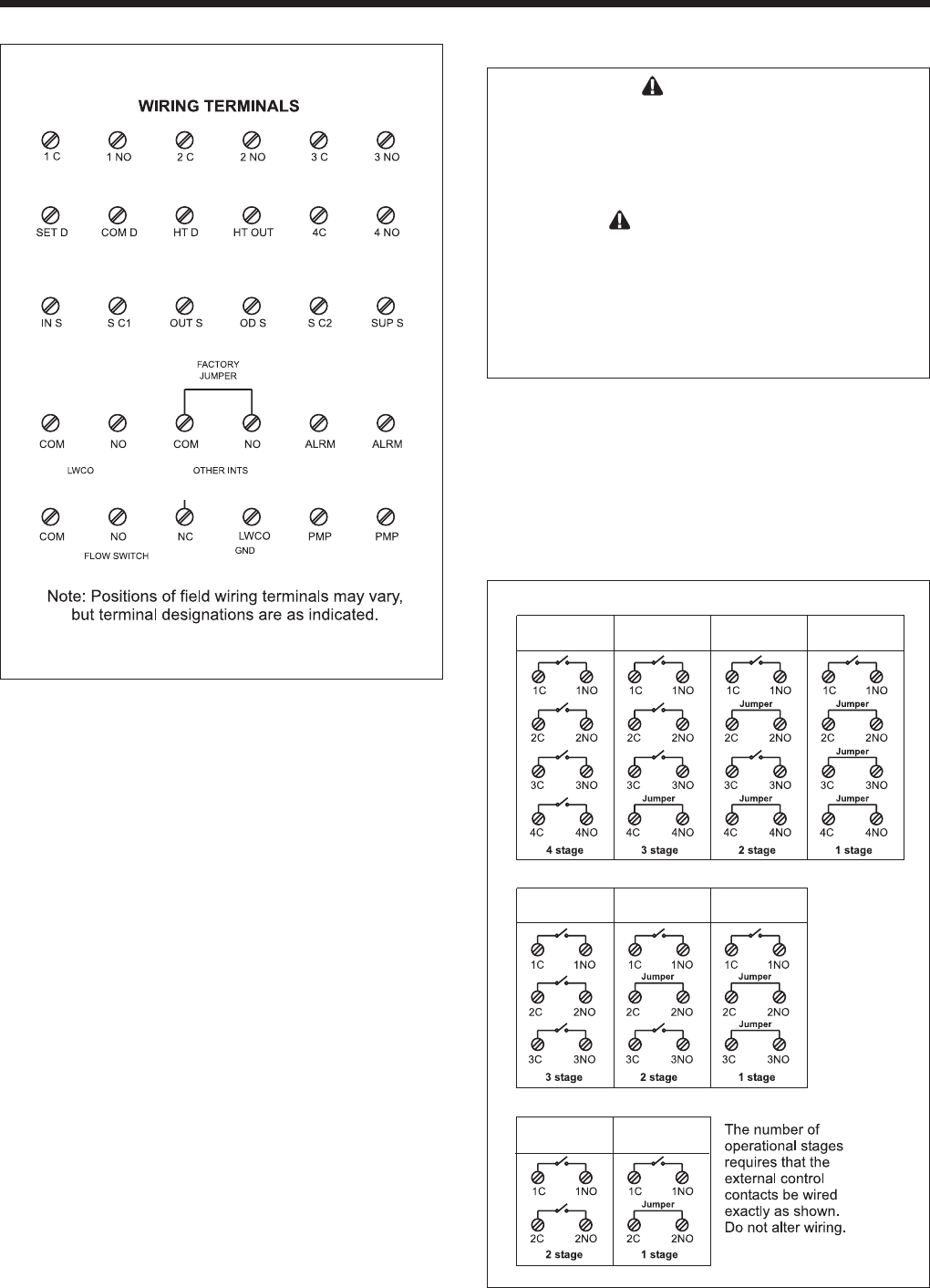

5.3 External Staging Control Wiring

WARNING

Improper eld wiring may result in re or explosion

which can cause property damage, severe injury,

or death. Make only wiring connections which are

in accordance with the Installation and Operation

manual.

AVERTISSEMENT

Un câblage incorrect lors de l’installation peut

causer un incendie ou une explosion pouvant

entraîner des dommages matériels, de graves

blessures ou la mort. Ne faire seulement que les

connexions conformes au Manuel d’installation et

d’exploitation.

The wiring methods in this section must be

used to connect an external staging control, such as a

multiple heater control, building automation system,

energy management system, etc.) Other wiring

methods may be unsafe.

Figure 9 shows how to wire the external

controller to the heater’s eld wiring panel, which is

located on the right side of the heater.

Figure 8. Field Wiring Panel

Other Field Interlocks: To install other eld-

wired devices to interlock with the heater (louver

switches, ow switches, etc.), remove the jumper

between the “COM” and “NO” terminals and wire the

device in series across these terminals. (See Section

5.3 for important information about external staging

controls and building automation systems.)

System Heat Demand: Remove the jumper

across the “COM D” and “Ht D” terminals, and

connect the zone pump or valve end switch,

thermostat, aquastat, or other indication of system heat

demand to these terminals. If no indication of a system

heat demand will be provided, the jumper must remain

in place. When jumpered, the temperature control

will always see a heat demand, and the Copper Brute

II pump (if equipped) or any pump with its contactor

connected to the “PMP” and “PMP” terminals will

run continuously. In addition, any device connected

through the “HT OUT” and “LWCO GND” terminals

for an external indication of the heat demand will

run continuously. See section 6 for more information

on the system heat demand for various modes of

operation.

Refer to Figures 23 through 25 for eld wiring of

additional components.

Figure 9. External Control Connection Wiring.

Model 1250, 1500, 1750 & 2000 (4-Stage Heater)

4 stage heater

using 4 control

output

s

4 s

tage heater

using 1 control

output

4 stage heater

using 2 control

output

s

4 s

tage heater

using 3 control

output

s

Model 1000 (3-Stage Heater)

3 stage heater

using 1 control

output

3 stage heater

using 2 control

output

s

3 s

tage heater

using 3 control

output

s

Model 750 & 500 (2-Stage Heater)

2 stage heater

using 1 control

output

2 stage heater

using 2 control

output

s