12

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

S1

S2

S3 S4

Learn Delete

Controls

ww

w

.Wayne-Dalt

o

n.c

o

m/

access

Fin

d

ou

t

mor

e

:

what’s

OPENING

you

r

world?

Wi

th Z-

W

ave

®

t

e

ch

no

lo

gy

y

ou

can

contr

ol y

ou

r

lig

h

t

s,

th

e

rmos

t

at

and

s

tar

t

your

m

o

r

n

ing

co

f

fee

,

all with

th

e sing

le

t

o

u

ch

of a

but

ton

.

P/

N

33598

2

Z-Wave

®

enabled

S1

S2

S3 S4

Learn Delete

Controls

w

ww

.Wayne-Dalt

o

n.c

o

m/

access

Fin

d

ou

t

mor

e

:

what’s

OPENING

yo

ur world?

Wi

th Z-Wave

®

t

ech

no

lo

gy

y

ou

can

contr

ol

y

ou

r

light

s,

th

e

rmos

t

at

and

s

t

ar

t

your

mo

r

n

ing

co

f

fee

,

al

l

with

t

h

e sing

le

t

o

u

c

h

of a

but ton

.

P/

N

33598

2

Z-Wave

®

enabled

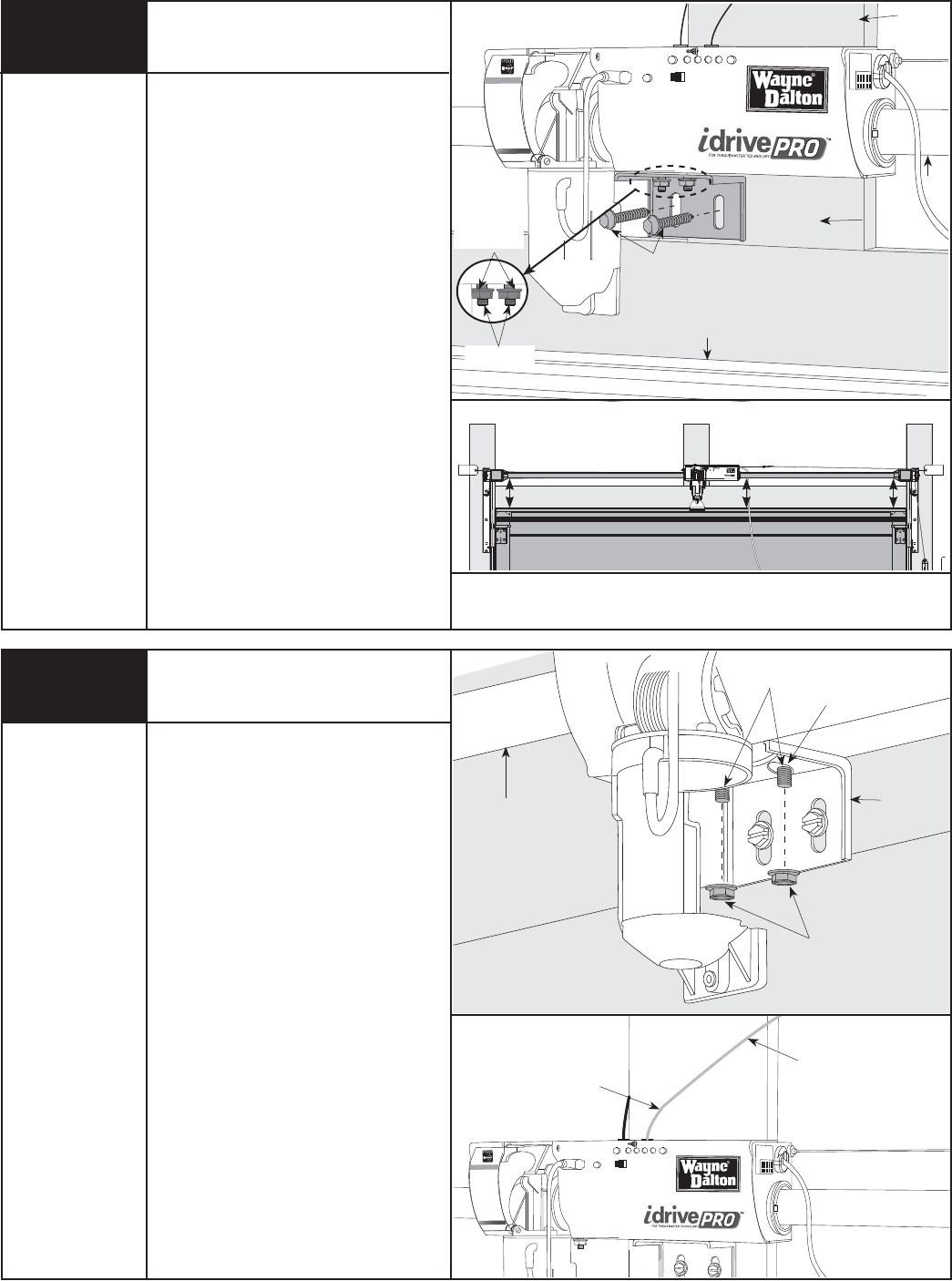

Positioning Support Bracket

NOTE: idrive

®

must be installed on a solid

mounting surface.

Locate the mounting surface. The mounting

surface is a vertical board running directly

above the center of the door. Remove

(2) 1/4”-20 flange nuts from bottom

of opener.

NOTE: Do not discard flange nuts.

Place the support bracket underneath

opener, to the right side of motor, centered

on mounting surface.

Using a tape measure, maintain equal

measurements between torque tube and top

of door at both ends and in center to ensure

torque tube is level. Once torque tube is

level, with idrive resting on support bracket,

drill 1/8” pilot holes for the lag screws.

Now secure support bracket to the mounting

surface with (2) 1/4” x 1-1/2" lag screws.

NOTE: If wood mounting surface is covered

with dry wall, use 1/4” x 2” lag screws.

1/4 x 1-1/2”

Lag Screws

Support

Bracket

1/4” - 20

Flange Nuts

Mounting

Studs

Mounting

Surface

(Header)

Top Of Door

Attaching Opener To

Support Bracket

Lift and slide the opener over the support

bracket, aligning the mounting studs with

the bracket slots. Loosely fasten to

mounting studs with the (2) 1/4”-20

flange nuts.

Alternately, the disconnect cable can be

pulled to allow motor to pivot up. This will

enable assembly of the support bracket to

the opener first, followed by leveling of the

torque tube and then attachment of support

bracket to mounting surface.

NOTE: Do not tighten 1/4”-20 flange

nuts to opener studs at this time.

Remove the orange label holding the

antenna wire. Straighten antenna wire and

angle it 45 degrees to the right.

NOTE: Do not coil the antenna wire. This

will reduce the radio signal range.

Antenna Wire

(2) 1/4”-20

Flange Nuts

Support

Bracket

Mounting

Studs

45° Angle

Tools Needed:

Step Ladder

Bracket

Slots

Torque Tube

Torque Tube

S1S2S3S4

Learn Delete

Controls

USING A TAPE MEASURE, MAINTAIN AN EQUAL MEASUREMENT “X” (TOP OF DOOR

TO BOTTOM OF TORQUEMASTER

®

TUBE) AT BOTH ENDS AND THE CENTER.

TOP SECTION

“X” “X” “X”

Tools Needed:

Power Drill

1/8” Drill Bit

7/16” Socket

Driver

Tape Measure

Step Ladder

4

5