10

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need.

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

Loose

Winding

Shaft

Cable

Drum

Left Hand Side

Single Spring Application

Groove

Flagangle

NOTE: If you just installed the

Torquemaster

®

Plus

counterbalance,

continue with Step 4 on page 12. If you

have the Torquemaster

®

counterbalance

system, complete Steps 2-3 on pages 10

and 11.

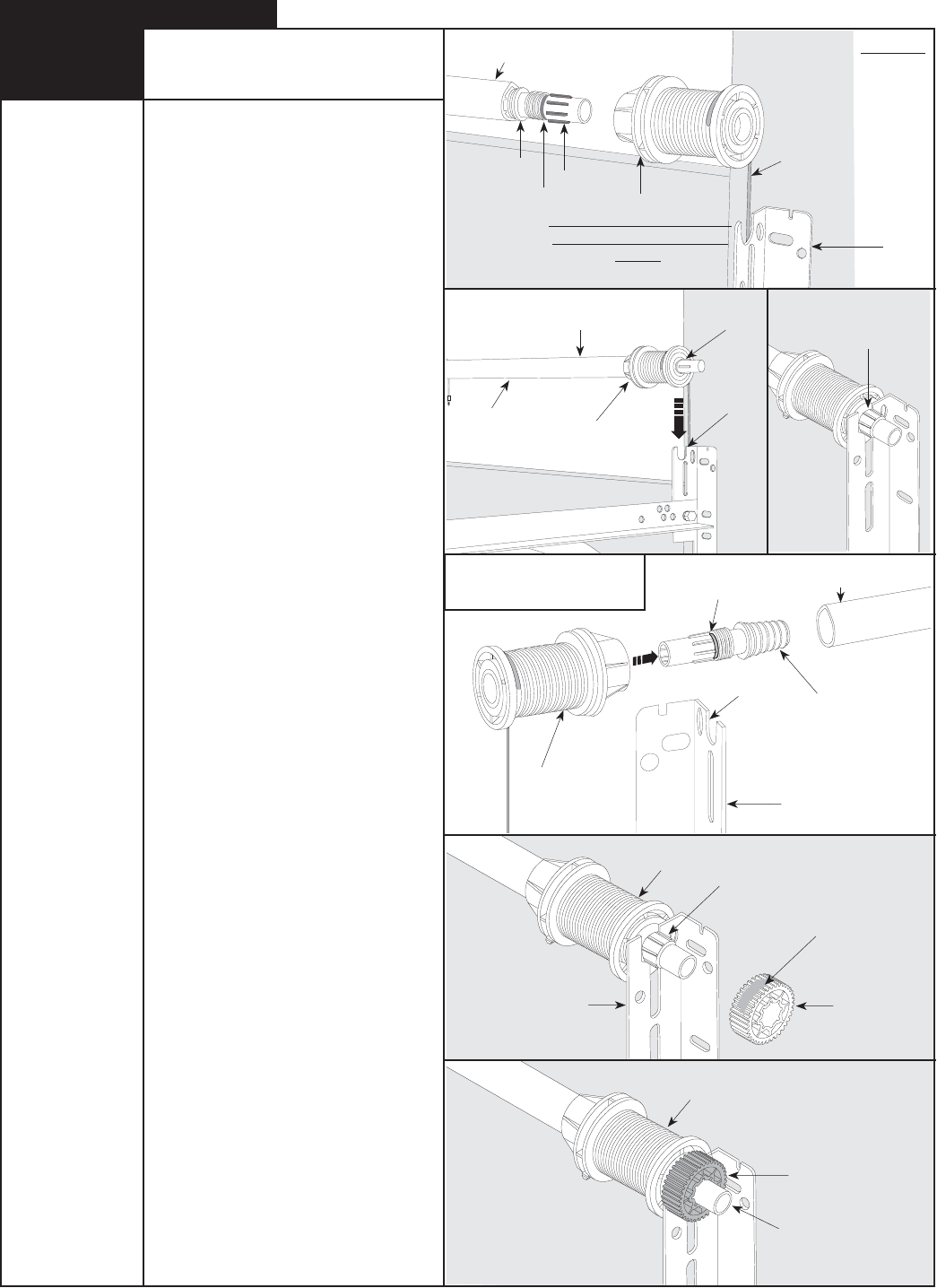

Shake the torque tube gently to extend the

winding shafts out about 5" on each side.

For single spring applications, there will be

no left hand spring in the torque tube.

Lift the torque tube and rest it on the top of

the flagangles. Orient torque tube so that

back of opener is flat against header/

mounting surface.

NOTE: Cable drums and torque tube are

cam shaped to fit together only one way.

Pre-wrap the Torquemaster

®

cable drum

with the counter balance cable 1/2 wrap

(see illustrations).

To install the cable drum, slide the cable

drum over the winding shaft until the cable

drum seats against the torque tube. The

winding shaft must extend past the cable

drum far enough to expose the splines and

the groove.

Align the winding shaft groove with

the round notch in the flagangle.

For double spring applications, repeat for

opposite side.

For single spring applications, pre-wrap the

left hand Torquemaster

®

cable drum with

counter balance cable 1/2 wrap and insert

loose winding shaft into the cable drum

prior to sliding the cable drum over the

torque tube.

NOTE: On single spring applications, take

care in handling the loose winding shaft

(left side) so that it does not slide back into

the torque tube.

Beginning with the right hand side, lubricate

entire circumference of the drive gear

with lubricating oil. Slide the drive gear onto

the winding shaft splines until it touches

the flagangle.

NOTE: On single spring applications,

no drive gear is required on the left side.

NOTE: If additional lubricating oil is

required “Dura-Lube Engine Oil Treatment”

is recommended.

Cable Drum/ Drive Gear

Installation

Winding

Shaft

Counterbalance

Cable

Torque

Tube

Cable Drum

Round

Notch

Winding

Shaft Groove

Winding

Shaft Splines

Lubricating

Oil

Drive

Gear

Flagangle

Drive

Gear

Winding

Shaft

Cable

Drum

Cable

Drum

Splines

Groove

Flag Angle

Round

Notch

2

TorqueMaster

®

Installation

Tools Needed:

Step Ladder

1/2 Wrap

Winding

Shaft Groove aligned

and seated in round

notch.

Cam Peak

Straight Up

TorqueMaster

®

Spring Tube

Assembly (Cam Peak Straight Up)

Cam Peak

Straight Up

Cable Drum

(Right hand cable drum shown, left

hand cable drum is symmetrically

opposite)