MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06

Page 24 of 68 flowserve.com

f) Compare the “adjusted Figure 4-16 loads” to the

values shown in figure 4-15. The lower of these

two values should be used as the adjusted figure 4-

15 values. (The HI standard also asks that figure 4-

15 loads be reduced if figure 4-17 or 4-18 values

are lower. Flowserve does not follow this step.)

g) Calculate the applied loads at the casing flanges

according to the coordinate system found in

figure 4-13. The 12 forces and moments possible

are Fxs, Fys, Fzs, Mxs, Mys, Mzs, Fxd, Fyd, Fzd,

Mxd, Myd and Mzd. For example, Fxd

designates Force in the “x” direction on the

discharge flange. Mys designates the Moment

about the “y”-axis on the suction flange.

h) Figure 4-14 gives the acceptance criteria

equations. For long coupled pumps, equation

sets 1 through 5 must be satisfied. For close

coupled and C-face pumps, only equation sets 1

and 2 must be satisfied.

i) Equation set 1. Each applied load is divided by

the corresponding adjusted figure 4-15 value.

The absolute value of each ratio must be less

than or equal to one.

j) Equation set 2. The summation of the absolute

values of each ratio must be less than or equal to

two. The ratios are the applied load divided by

the adjusted figure 4-16 values.

k) Equation sets 3 and 4. These equations are

checking for coupling misalignment due to nozzle

loading in each axis. Each applied load is divided

by the corresponding adjusted load from figure 4-17

and 4-18. The result of each equation must be

between one and negative one.

l) Equation set 5. This equation calculates the total

shaft movement from the results of equations 3

and 4. The result must be less than or equal to one.

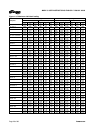

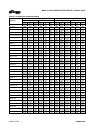

Figure 4-11: Casing material correction factors

Material Group No.

1.0 1.1 2.1 2.2 2.4 2.8 3.2 3.4 3.5 3.7 3.8 3.17 Ti Cr

Austenitic steels Nickel and nickel alloys

Temp

Temp

DCI

Carbon

Steel

Type

304

and

304L

Type

316

and

316L

Type

321

CD-

4MCu Nickel Monel Inconel

Hast

B

Hast

C

Alloy

20

Ti,

Ti-

Pd,

Zr

High

Chrome

-18 to

171

340

-129 -200 – – 1.00 1.00 1.00 – 0.50

–

–

–

–

0.83

–

–

-73 -100

– –

1.00 1.00 1.00 1.00 0.50 0.83 0.93 1.00 1.00 0.83 0.89 –

-29 -20 0.89 1.00 1.00 1.00 1.00 1.00 0.50 0.83 0.93 1.00 1.00 0.83 0.89 0.65

38 100 0.89 1.00 1.00 1.00 1.00 1.00 0.50 0.83 0.93 1.00 1.00 0.83 0.89 0.65

93 200 0.83 0.94 0.83 0.86 0.93 1.00 0.50 0.74 0.88 1.00 1.00 0.72 0.86 0.65

150 300 0.78 0.91 0.75 0.78 0.83 0.92 0.50 0.69 0.82 1.01 1.01 0.65 0.81 0.65

205 400 0.73 0.88 0.69 0.72 0.69 0.85 0.50 0.67 0.77 0.98 0.98 0.58 0.69 0.65

260 500 0.69 0.83 0.63 0.67 0.64 0.80 0.50 0.66 0.74 0.92 0.92 0.54 0.57

–

315 600 0.65 0.76 0.60 0.63 0.60 0.77 0.50 0.66 0.74 0.84 0.84 0.50 0.45

–

344 650 0.63 0.74 0.60 0.62 0.60

– –

0.66 0.73 0.82 0.82

–

0.39

–

370 700 – 0.74 0.59 0.60 0.58

– –

0.66 0.73 0.79 0.79

–

0.33

–