MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06

Page 10 of 68 flowserve.com

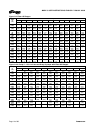

Figure 2-2

2.3.2 Lifting pump, motor and baseplate assembly

2.3.2.1 Horizontal assemblies

If the baseplate has lifting holes cut in the sides at the

end (Type A Group 3, Type D and Type E bases) insert

lifting S hooks at the four corners and use slings or

chains to connect to the lifting eye. (Figure 2-1.) Do not

use slings through the lifting holes.

For other baseplates, sling around the pump discharge

nozzle, and around the outboard end of the motor frame

using choker hitches pulled tight. (Figure 2-1.)

The sling should be positioned so the weight is not

carried through the motor fan housing. Make sure the

completion of the choker hitch on the discharge

nozzle is toward the coupling end of the pump shaft

as shown in figure 2-1.

2.3.2.2 In-Line assemblies

If the pump is to be lifted as a complete assembly, the

motor lifting lugs must be used to ensure that the

assembly does not flip over. Check with motor

supplier for lifting lug capacities. If there is any

uncertainty, the motor should be removed prior to

moving the pump. (Figure 2-2.)

2.4 Storage

Store the pump in a clean, dry location

away from vibration. Leave flange covers in place to

keep dirt and other foreign material out of pump

casing. Turn the pump shaft at regular intervals to

prevent brinelling of the bearings and the seal faces,

if fitted, from sticking.

The pump may be stored as above for up to 6

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.4.1 Short term storage and packaging

Normal packaging is designed to protect the pump

and parts during shipment and for dry, indoor storage

for up to six months or less. The following is an

overview of our normal packaging:

•

All loose unmounted items are packaged in a

water proof plastic bag and placed under the

coupling guard

• Inner surfaces of the bearing housing, shaft (area

through bearing housing) and bearings are coated

with Cortec VCI-329 rust inhibitor, or equal.

Bearing housings are not filled with oil

prior to shipment

•

Regreasable bearings are packed with grease

(EXXON POLYREX EM for horizontal pumps and

EXXON UNIREX N3 for In-Line pumps)

•

The internal surfaces of ferrous casings, covers,

flange faces, and the impeller surface are

sprayed with Cortec VCI-389, or equal

• Exposed shafts are taped with Polywrap

• Flange covers are secured to both the suction

and discharge flanges

• In some cases with assemblies ordered with

external piping, components may be

disassembled for shipment

• The pump must be stored in a covered, dry location

2.4.2 Long term storage and packaging

Long term storage is defined as more than six

months, but less than 12 months. The procedure

Flowserve follows for long term storage of pumps is

given below. These procedures are in addition to the

short term procedure.

• Each assembly is hermetically (heat) sealed from

the atmosphere by means of tack wrap sheeting

and rubber bushings (mounting holes)

• Desiccant bags are placed inside the tack

wrapped packaging

•

A solid wood box is used to cover the assembly

This packaging will provide protection for up to twelve

months from humidity, salt laden air, dust etc.