MARK 3 USER INSTRUCTIONS ENGLISH 71569102 08-06

Page 11 of 68 flowserve.com

After unpacking, protection will be the responsibility of

the user. Addition of oil to the bearing housing will

remove the inhibitor. If units are to be idle for extended

periods after addition of lubricants, inhibitor oils and

greases should be used. Every three months, the pump

shaft should be rotated approximately 10 revolutions.

2.5 Recycling and end of product life

At the end of the service life of the product or its parts,

the relevant materials and parts should be recycled or

disposed of using an environmentally acceptable

method and in accordance with local regulations. If the

product contains substances that are harmful to the

environment, these should be removed and disposed of

in accordance with current local regulations. This also

includes the liquids and/or gases that may be used in

the "seal system" or other utilities.

Make sure that hazardous substances are

disposed of safely and that the correct personal

protective equipment is used. The safety

specifications must be in accordance with the current

local regulations at all times.

3 DESCRIPTION

3.1 Configurations

The Durco Mark 3 chemical process pumps are

metallic , single stage, sealed, centrifugal pumps.

The horizontal family conforms to ASME B73.1M,

which has a centerline discharge and is represented

by our Standard, Sealmatic, Unitized self-priming,

Recessed impeller and Lo-Flo pump models. The

vertical pump or In-Line conforms to ASME B73.2M.

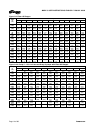

Figure 3-1: Nameplate mounted to housing

Serial No.

Equipment No.

Purchase Order

Model

Size

MDP

Material

Date DD/MMM/YY

2K6X4 M-13A/12.5 RV

The Prima

3 ™

is an ANSI 3A power end adapted to other

pump models from Flowserve as well as from other

pump manufacturers. Only the information in this

manual involving the ANSI 3A power end may be used

when Installing, Operating or Maintaining a pump that

has been upgraded to a Prima

3 ™

. All other information

regarding the pump type must be obtained from the

original pump manufacturer’s User Instructions.

3.2 Nomenclature

The pump size will be engraved on the nameplate

typically as below:

2 K 6 X 4 M - 13 A /12.5 RV

• Frame size

“2" indicates a medium size pump frame (in this

example, a Group 2)

1 = Group 1 (small frame)

2 = Group 2 (medium frame)

3 = Group 3 (large frame)

•

Power end

K = Mark 3 style power end

Mark 3A – Standard

ANSI 3A – Optional (3 year guarantee)

J = Mark 3 style PE arranged for Mark 2 wet end

(No letter and no preceding number indicates a

Mark 2 power end)

• “6” = nominal suction port size (in.)

• “4” = Nominal discharge port size (in.)

• Modifier for “specialty pumps”

Blank or no letter = standard pump

M = Sealmatic

R = recessed impeller

US = unitized self-priming

V = vertical In-Line

LF = Lo-Flo

• Nominal maximum impeller diameter. “13” = 13 in.

• Pump design variation

A = This pump has been redesigned from an earlier

version. The impeller and casing are no longer

interchangeable with the earlier version.

H = This pump is designed for a higher flow capacity

than another pump with the same basic

designation. (Examples: 4X3-10 and 4X3-10H;

6X4-10 and 6X4-10H; 10X8-16 and 10X8-16H.

HH = This pump is designed for a higher head than

another pump with the same basic designation.

(Example: 4X3-13 and 4X3-13HH.)

• Actual impeller size

“12.5” = 12 ½ in. diameter; 8.13 = 8 LQ

10.75 = 10 ¾ in

(Previous annotation: 124 = 12

4

/

8

or 12 ½ in.

diameter; 83 = 8 LQ

• Impeller style

RV = reverse vane impeller; OP = Open impeller