Part III: 1-13

Oil in Water Part III

Teledyne Analytical Instruments

manually calibrating the analyzer system.

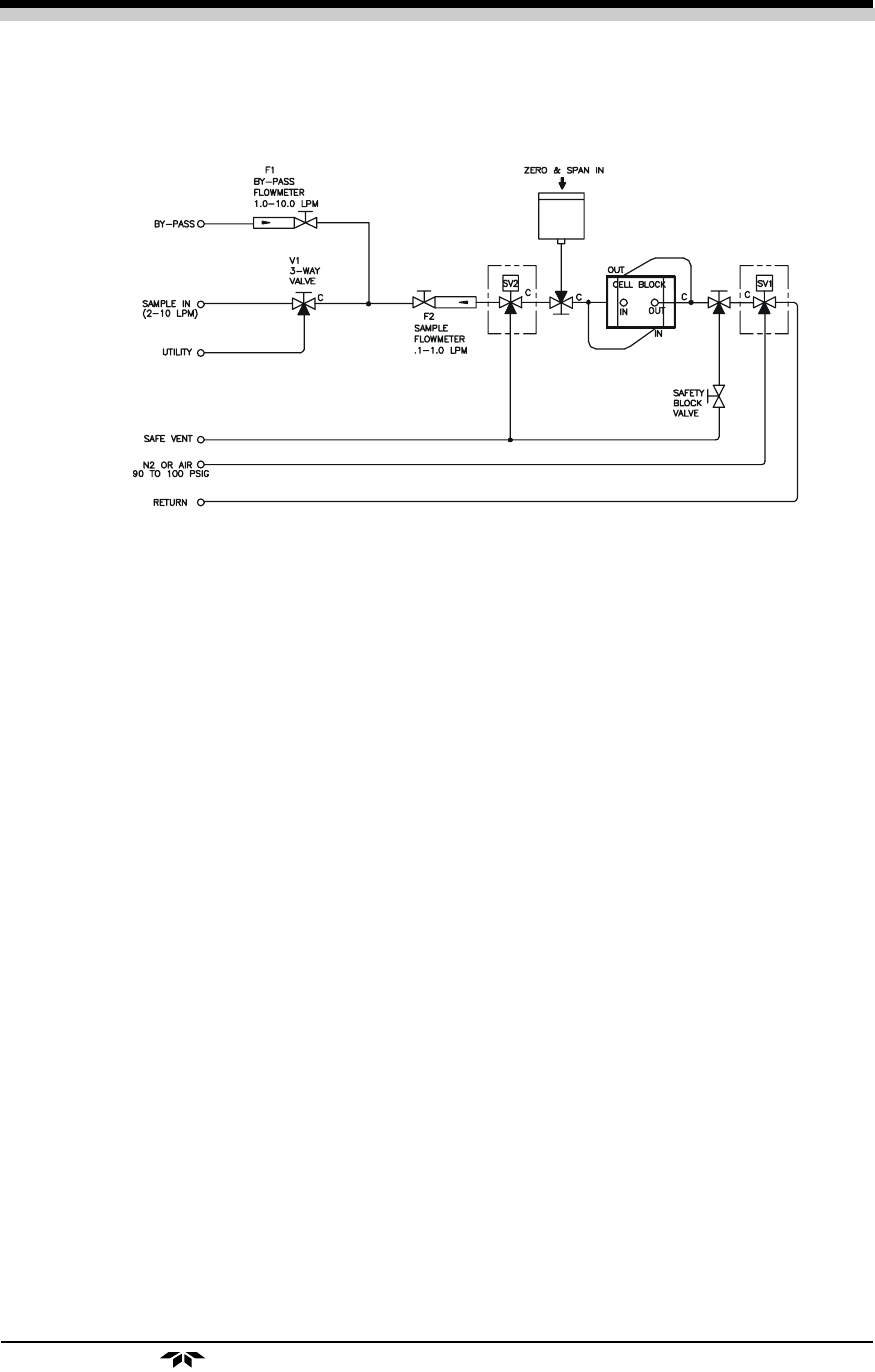

Oil in Water Piping Diagram (simplest)

Homogenizing

Input flowrate to the sample homogenizer module inlet is precisely and

accurately controlled by a mechanical flow controller designed for continuous

duty. Because of the style, construction, and position in the sample system, the

controller solves many of the problems associated with sample handling at the

flowrates dictated by the preconditioning technique. For sample concentration

over 20 ppm total oil homogenization is always required-regardless of the

analyzer used to measure the oil above 20 ppm, most waters are so enriched that

oils do not remain homogenized nor miscible enough to measure accurately.

3.4.2 Zero Water Preconditioning System

Since the analyzer operates at a fixed measuring wavelength, and many

soluble organic compounds absorb to some degree at this wavelength, the

effects of organics other than oil must be eliminated from the analysis. Thus, a

solution is prepared that is essentially free of oil, but retains all the other organic

characteristics of the unconditioned sample. When presented to the analyzer, the

absorption caused by the unknown organic compounds in this oil-free water can

be nullified by eliminating any electronic signal that is generated while the

solution is undergoing analysis.

The nondissolved oil is removed by coarse filtering, and the dissolved oil

removed by fine filtering, the water contains only the non-oil organic fraction of

the effluent stream; i.e., it can be used as a reference or “zero oil” water. During

the zero cycle, all solenoid valves are energized and the zero water is pumped

through SV3 to the sample cell. Since turbidity is ratioed out by the electro-

V5

V6

V7