15

GB

8.1. Installation

[Fig. 8.1.1] (P.3)

<A> Without detachable leg <B> With detachable leg

A

M10 anchor bolt procured at the site.

B

Corner is not seated.

C

Fixing bracket for the hole-in anchor bolt (3 locations to x with screws).

D

Detachable leg

Fix unit tightly with bolts so that unit will not fall down due to earthquakes or •

strong winds.

Use concrete or an angle bracket as the foundation of unit.•

Vibration may be transmitted to the installation section and noise and •

vibration may be generated from the oor and walls, depending on the

installation conditions. Therefore, provide ample vibrationproong (cushion

pads, cushion frame, etc.).

Build the foundation in such way that the corner of the installation leg is •

securely supported as shown in the gure. (Fig. 8.1.1)

When using a rubber isolating cushion, please ensure it is large enough to

cover the entire width of each of the unit's legs. If the corners are not rmly

seated, the installation feet may be bent.

The projecting length of the anchor bolt should be less than 30 mm.•

Hole-in anchor bolts are not compatible with this product. However, if xing •

brackets are mounted on the 4 locations (6 locations: P450, EP300) of the

unit attachment part, hole-in anchor bolts can be used.

[Fig. 8.1.2] (P.3)

A

Screws

The detachable leg can be removed at the site.•

Detaching the detachable leg•

Loosen the three screws to detach the detachable leg (Two (three: P450,

EP300) each in the front and back).

If the base leg nish is damaged when detaching, be sure to repair at the

site.

Warning:

Be sure to install unit in a place strong enough to withstand its weight.•

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

Have installation work in order to protect against strong winds and •

earthquakes.

Any installation deciency may cause unit to fall down, resulting in a

personal injury.

When building the foundation, give full attention to the oor strength, drain water

disposal <during operation, drain water ows out of the unit>, and piping and

wiring routes.

Precautions when routing the pipes and wires below the unit (Without

detachable leg)

When routing the pipes and wires below the unit, be sure that the foundation and

base work do not block the base through-holes. Also make sure the foundation

is at least 100 mm high so that the piping can pass under the unit.

8. Installation of unit

9. Refrigerant piping installation

The pipe is connected via a terminal-branch type connection in which refrigerant

piping from the outdoor unit is branched at the terminal and is connected to each

of the indoor units.

The method of pipe connection is as follows: are connection for the indoor

units, gas pipes and liquid pipes for outdoor units, brazed connection. Note that

the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas from leaking while

using re or ame. If the refrigerant gas comes in to contact with a ame

from any source, such as a gas stove, it breaks down and generates

a poisonous gas which can cause gas poisoning. Never weld in an

unventilated room. Always conduct an inspection for gas leakage after

installation of the refrigerant piping has been completed.

Caution:

Do not vent R410A into the atmosphere.•

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol •

with a Global Warming Potential (GWP) = 1975.

9.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes. (Refer to the table on the right.)

1 Use the following materials for refrigeration piping.

Material: Use copper alloy seamless pipes made of phosphorus •

deoxidized copper. Ensure the inner and outer surfaces of the pipes are

clean and free from hazardous sulfur, oxide, dusts, shaving particles, oils,

and moisture (contamination).

Size: Refer to item 9.2. for detailed information on refrigerant piping •

system.

2 Commercially available piping often contains dust and other materials.

Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the

piping during installation.

4 Reduce the number of bending portions as much as possible, and make

bending radii as big as possible.

5 For indoor and outdoor branching, be sure to use the following twinning pipe

sets (sold separately).

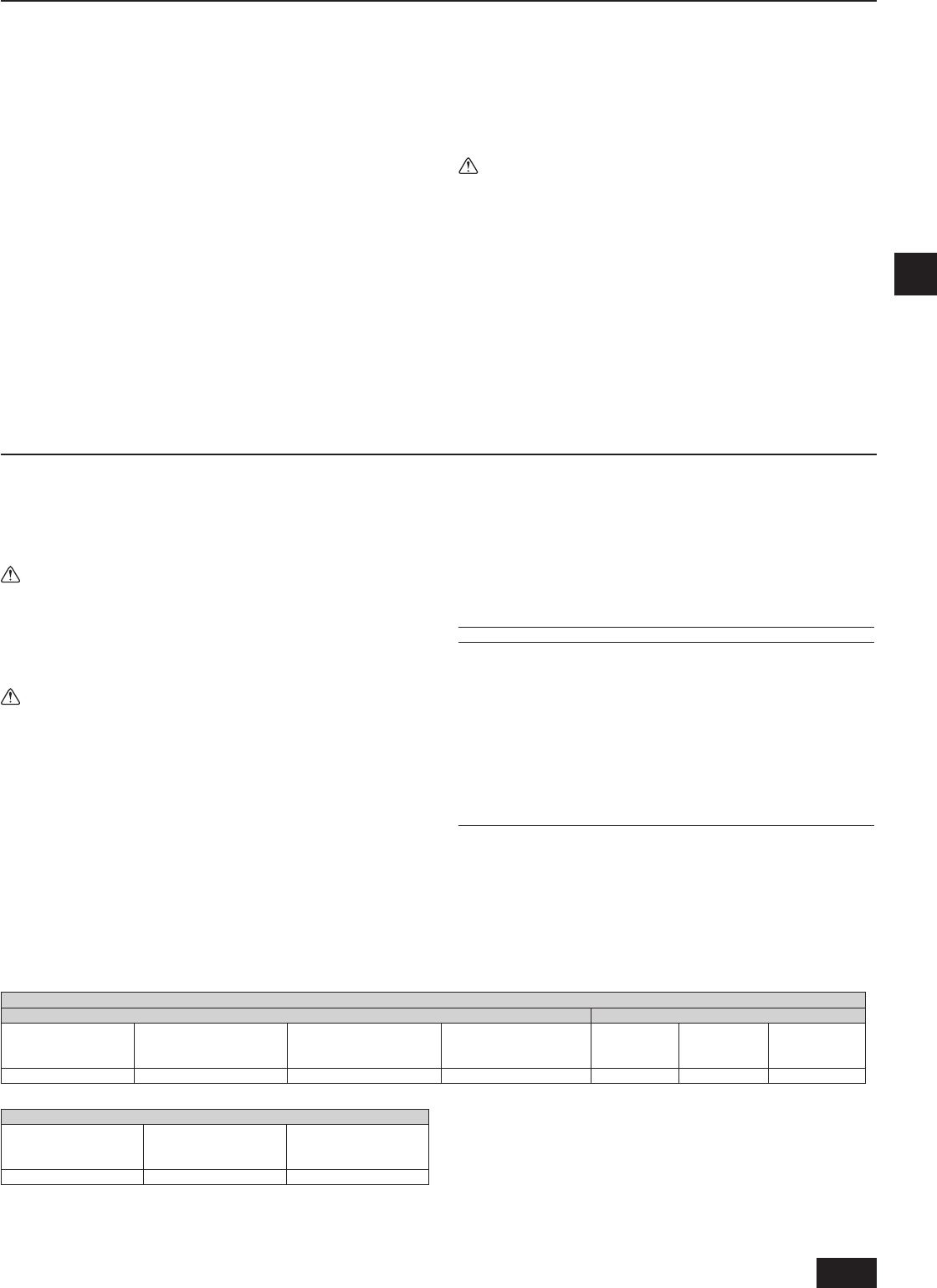

Copper pipe size and radial thickness for R410A CITY MULTI.

Size (mm) Size (inch) Radial thickness (mm) Pipe type

ø6.35 ø1/4" 0.8 Type-O

ø9.52 ø3/8" 0.8 Type-O

ø12.7 ø1/2" 0.8 Type-O

ø15.88 ø5/8" 1.0 Type-O

ø19.05 ø3/4" 1.2 Type-O

ø19.05 ø3/4" 1.0 Type-1/2H or H

ø22.2 ø7/8" 1.0 Type-1/2H or H

ø25.4 ø1" 1.0 Type-1/2H or H

ø28.58 ø1-1/8" 1.0 Type-1/2H or H

ø31.75 ø1-1/4" 1.1 Type-1/2H or H

ø34.93 ø1-3/8" 1.2 Type-1/2H or H

ø41.28 ø1-5/8" 1.4 Type-1/2H or H

* For pipe sized ø19.05 (3/4") for R410A air conditioner, choice of pipe type is

up to you.

Indoor twinning pipe set model

Line branch Header branch

Lower stream unit

model

Less than 200 in total

Lower stream unit model

More than 201 and less

than 400 in total

Lower stream unit model

More than 401 and less

than 650 in total

Lower stream unit model

More than 651 in total

4 branching 8 branching 10 branching

CMY-Y102S-G2 CMY-Y102L-G2 CMY-Y202-G2 CMY-Y302-G2 CMY-Y104-G CMY-Y108-G CMY-Y1010-G

Outdoor twinning kit model

Total outdoor model

P500 ~ P650

EP400 ~ EP600

Total outdoor model

P700 ~ P900

Total outdoor model

P950 ~ P1250

EP650 ~ EP900

CMY-Y100VBK2 CMY-Y200VBK2 CMY-Y300VBK2

WT05962X01_GB.indd 15 2010/08/26 19:20:57