39

Display

Abnormal point and detecting method

Causes

Check points

Operation mode: When drain pump turns on as float switch detects to be in the water except during cooling/dry mode

Check the drain function.

Check moving part of float switch.

Check the value of resistance with the

float switch ON/OFF.

Defective drain

Clogged drain pump

Clogged drain pipe

Adverse flow of drain in other units

Defective moving part of float switch

Foreign matter on the moving

part of float switch(ex. sludge etc.)

Defective float switch

Refrigerant shortage

When the conditions of below detecting

mode or are satisfied during the

compressor operation.

<Detecting mode >

When the below conditions are satisfied

completely.

1. Compressor is operating in HEAT mode.

2.

Discharge superheat is 80 [144

°

F] or more.

3. Difference of outer temperature thermistor

(TH7) and outdoor piping temp. thermistor

(TH3) applies to the formula of

(TH7-TH3)<5 [9°F] .

4. High-pressure sensor is below about

2.04MPa [296PSIG] .

<Detecting mode >

When the below conditions are satisfied

completely.

1. Compressor is operating.

2. When cooling, discharge superheat is 80

[144°F] or more.

When heating, discharge superheat is 90

[162°F] or more.

High pressure sensor is below about

2.32MPa [337PSIG] .

Gas leakage, Gas shortage

When heating operation, refrigerant

shortage feeling operation (When

heating, airflow or thermo OFF are

mixed-operation, it causes a refrigerant

shortage operation.)

Ball valve performance failure

(not full opened.)

Error detection of discharge superheat

1) High-pressure sensor defective

2) Discharge temperature thermistor

defective

3) Thermistor input circuit defective and

high-pressure sensor defective

in multi controller board

Error detection of TH7/TH3

1) Thermistor defective

2) Thermistor input circuit defective in

multi controller board

Check the refrigerant amount.

Check the operation condition and

refrigerant amount.

Check the ball valve is fully open.

1) Check the ball valve is fully open.

2) Check the resistance of discharge

temperature thermistor.

3) According to “Outdoor unit functions”,

set the SW2 and check the high-

pressure sensor level.

According to “Outdoor unit functions”,

check the discharge temp. thermistor

level. When the high-pressure sensor

and discharge temp. thermistor are

normal, if the above mentioned detecting

pressure level and temp. are big different

from the actual pressure and temp.

replace the multi controller board.

1) Check the resistance of thermistor.

2) According to “Outdoor unit functions”,

check the outdoor pipe temp. thermistor

level.

3) According to “Outdoor unit functions”,

check the outer temp. thermistor level.

1501

Water leakage

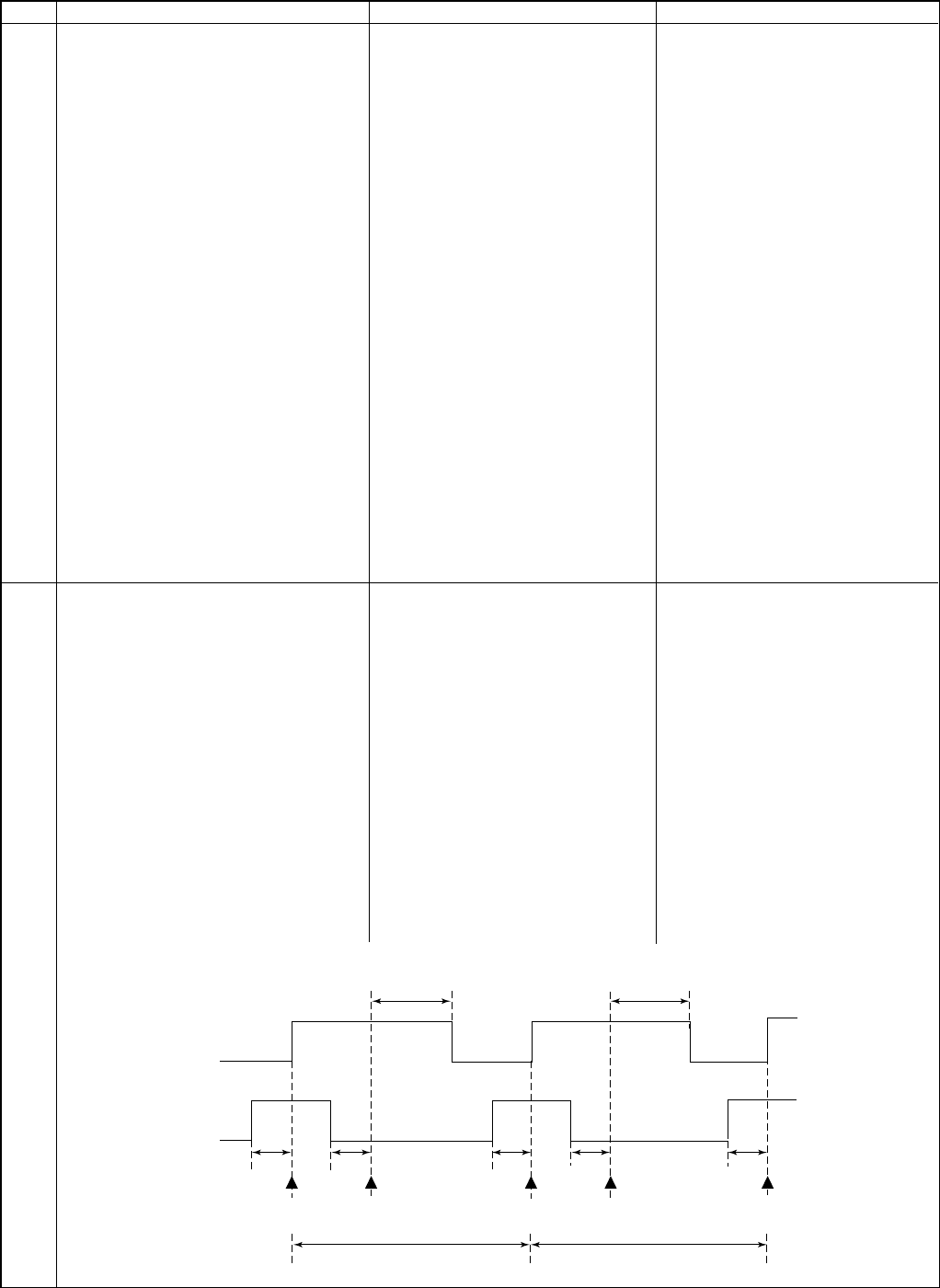

1. Suspensive Abnormality when float switch

detects to be in the water and drain pump

turns on and off except during cooling or dry

mode.

2. Abnormal when detecting that the drain

pump turns on and off again within 1 hour

after the detection of water leakage

suspensive abnormality, and repeats the

detection twice. <2500> is displayed.

3. The unit continues to detect abnormality

while turned off.

4. To release water leakage suspensive

abnormality

· When not detecting that the drain pump

turns off and on within 1 hour after

detecting suspensive abnormality.

· When turning to cooling operation or dry

operation.

· Detected that [liquid pipe temperature –

room temperature] -10deg[-18°F]

2500

(Float

switch

model)

6 min.6 min.

15 sec.

In the water

Water leakage suspensive abnormality

In the water

Water leakage abnormality

In the air In the water In the air

15 sec.

Within 1 hour Within 1 hour

15 sec. 15 sec.

15 sec.

ON

OFF

Drain pump

Float switch

ON

OFF