20

7

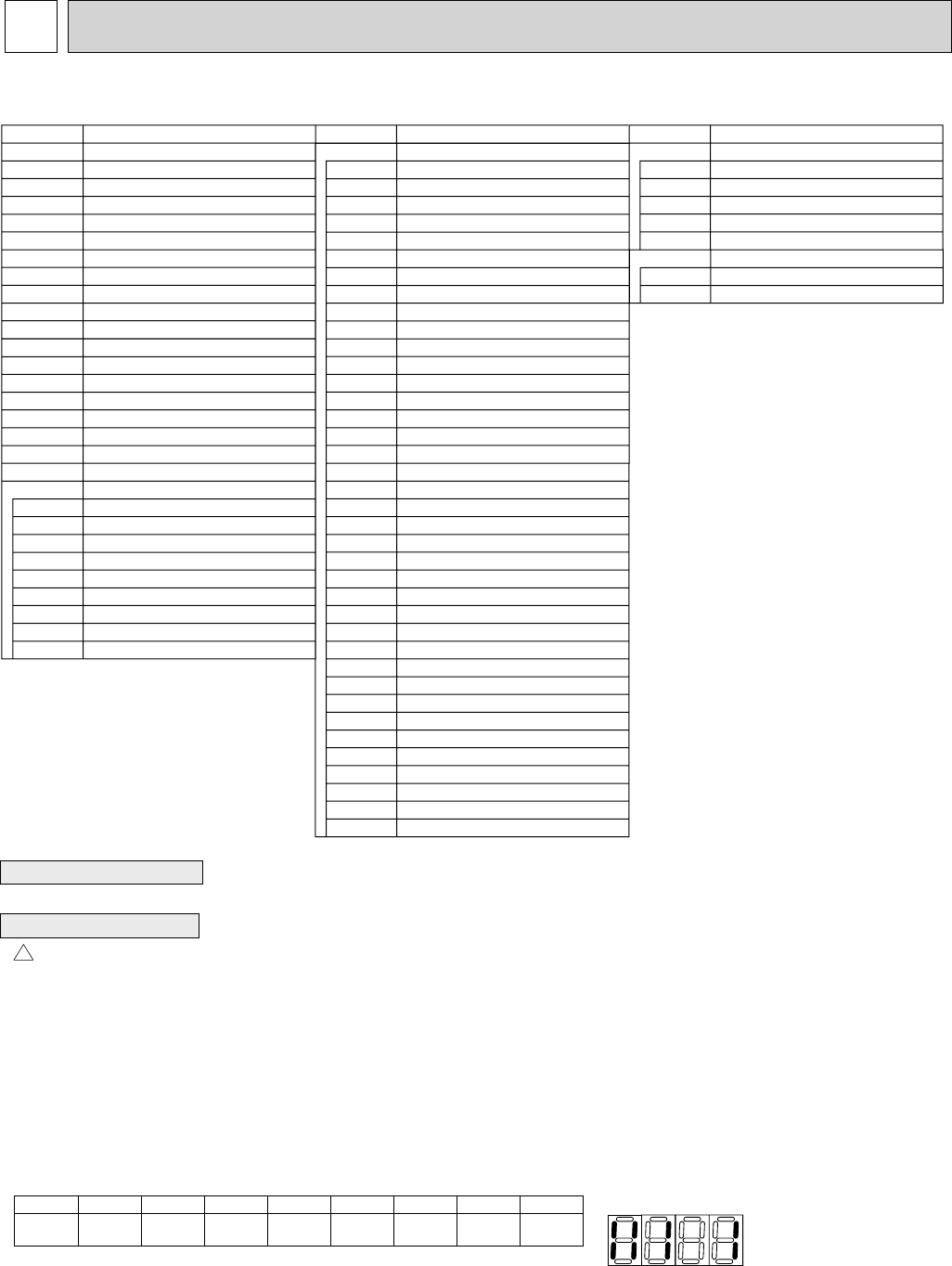

WIRING DIAGRAM

PUMY-P48NHMU PUMY-P48NHMU-BS PUMY-P48NHMU1 PUMY-P48NHMU1-BS

12345678

[Example]

When the compressor and

SV1 are turned during cooling

operation.

SYMBOL NAME SYMBOL NAMESYMBOL NAME

TB1 Terminal Block <Power Supply>

TB3 Terminal Block <Transmission>

TB7 Terminal Block <Centralized Control>

MC Motor for Compressor

MF1,MF2 Fan Motor

21S4 Solenoid Valve<Four way valve>

SV1 Solenoid Valve<Bypass valve>

TH3

Thermistor<Outdoor Pipe Temperature>

TH4 Thermistor<Discharge Temperature>

TH6

Thermistor<Low Pressure Saturated Temperature>

TH7 Thermistor<Outdoor Temperature>

TH8 Thermistor<Heatsink>

63HS

High Pressure Sensor<Discharge Pressure>

63H High Pressure Switch

63L Low Pressure Switch

CB Main Smoothing Capacitor

ACTM

DCL

Active filter Module

RS Rush Current Protect Resistor

P.B. Power Circuit Board

Connection Terminal<U/V/W-Phase>

U/V/W

MULTI.B.

Multi Controller Board

Fuse<6.3A>

F1,F2

Fuse<3A>

F500

Switch<Display Selection>

SW1

Switch<Function Selection>

SW2

Switch<Test Run>

SW3

Switch<Model Selection>

SW4

Switch<Function Selection>

SW5

Switch<Function Selection>

SW6

Switch<Function Selection>

SW7

Switch<Function Selection>

SW8

Switch<Unit Address Selection, 1s digit>

SWU1

Switch<Unit Address Selection, 10ths digit>

SWU2

Transformer

TRANS

Digital Indicator<Operation Inspection Display>

LED1,2

LED<Power Supply to Main Microcomputer>

LED3

Connector<Multi System>

CNS1

Connector<Centralized Control>

CNS2

Connector<To Noise Filter Circuit Board>

CNAC

Connector<Power circuit board>

CNDC

Connector<To Power Circuit Board>

CN2

Connector<To Power Circuit Board>

CN4

Connector<Centralized Control Power Supply>

CN40

Connector<For storing Jumper Connector>

CN41

Connector<Thermistor>

TH3

Connector<Thermistor>

TH4

Connector<Thermistor>

TH7/6

Connector<High Pressure Sensor>

63HS

Connector<High Pressure Switch>

63H

Connector<Low Pressure Switch>

63L

Connector<Fan Motor>

CNF1,CNF2

Connector<Four-way Valve>

21S4

Connector<Bypass Valve>

SV1

Connector<For Option>

SS

Connector<For Option>

CN3D

Connector<For Option>

CN3S

Connector<For Option>

CN3N

Connector<For Option>

CN51

Relay

X501~505

M-P.B.

Connector<To Noise Filter Circuit Board>

Transmission Power Board

CN1

Connector<To Multi Controller Board>

CN2

Terminal<L/N-Phase>

TAB-S/T

Terminal<DCVoltage>

TAB-P/P1/P2

Terminal<DCVoltage>

TAB-N/N1/N2

Connector

CN2~5

N.F. Noise Filter Circuit Board

Connection Lead<L-Phase>

LI/LO

Connection Lead<N-Phase>

NI/NO

Connection Terminal<Ground>

EI

Connector

CNAC1/2

Connector

CN5

Connector

CNDC

Connector

CNAF

Inverter

IPM

Light Emitting Diodes <Inverter Control Status>

LED1

Reactor

Bit

Indication

1

Compressor

operated

2

52C

3

21S4

4

SV1

5

(SV2)

6

–

7

–

8

Always lit

During normal operation

The LED indicates the drive state of the controller in the outdoor unit.

When faults requiring inspection occurs

The LED alternately indicates the inspection code and the location of the unit in which

the fault has occurred.

Use copper supply wires.

NOTES:

1.Refer to the wiring diagrams of the indoor units for details on wiring of each indoor unit.

Self-diagnosis function

The indoor and outdoor units can be diagnosed automatically using the self-diagnosis switch

(SW1) and LED1, LED2 (LED indication) found on the multi-controller of the outdoor unit.

LED indication : Set all contacts of SW1 to OFF.

Cautions when Servicing

Caution for electrical work

!

WARNING: When the main supply is turned off, the voltage [340 V] in the main capacitor will drop to 20 V in approx. 2 minutes (input voltage: 240 V).

When servicing, make sure that LED1, LED2 on the outdoor circuit board goes out, and then wait for at least 1 minute.

Components other than the outdoor board may be faulty: Check and take corrective action, referring to the service manual.

Do not replace the outdoor board without checking.