Commercial Pool Heaters

CLEANING AND

MAINTENANCE Continued

If the air pressure switch does not make within 60 seconds from the

time the fans turn ON, the ignition module will go into a soft

lockout period (approximately 5 minutes in duration) during which

time the fans are turned off and the module shows the Low Air flash

code. If necessary, soft lockout can be circumvented by cycling

power using the ON/OFF switch to cycle power to the unit.

Note:

If the pool heater has been firing recently, allow the pool

heater to cool for five minutes with the fans running before

beginning the adjustment procedure.

Retain the plastic caps removed from the tees for

reinstallation when complete.

Adjustment Procedure

1. Remove the upper front jacket panels from the unit to access

the upper chamber.

2. Slightly loosen screws that attach fan transition box to metal

base (see Figure 53).

3. Depending on model, the air shutter(s) may be located either

on the side or the rear of the fan duct. Locate the air shutter at

the side/rear of the fan duct (see Figure 52 and 54). Move the

air shutter towards the rear or left side of the unit to increase air

pressure. Move the air shutter towards the front or right side of

the unit to decrease air pressure.

4a.The 500,000 - 750,000 Btu/hr models have one fan with a side

mounted air shutter. The differential for these models is

nominally 1.5 - 1.65 inches water column.

4b.On the 990,000 - 2,070,000 Btu/hr models adjust the air shutter

on the left fan until the differential pressure is nominally

1.1 - 1.3 inches water column.

Note:

The air chamber pressure

is 1.2 inches water column for liquefied petroleum (L.P.) and

1.4 inches water column for natural.

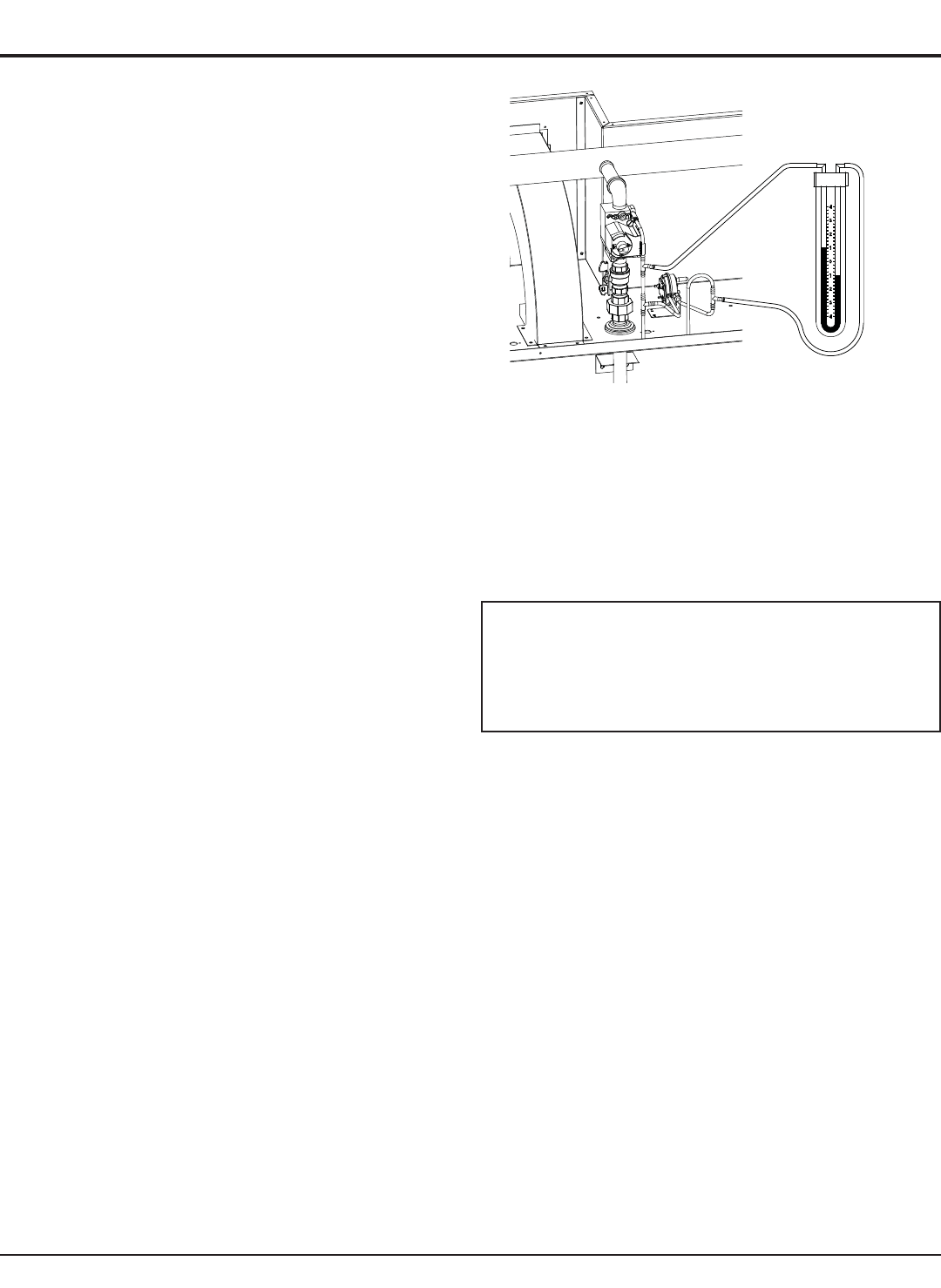

5. Attach one manometer hose to the barb located on the back of

the pressure switch. Attach the other manometer hose to the

capped tee barb spliced into the rubber hose running into the

combustion chamber (see Figure 55).

6. Adjust the air shutter on the right fan until the differential

pressure is nominally 1.1-1.3 inches water column.

7. Once the adjustment procedure is complete, reattach the cap to

the tee in the hose and the pressure switch and check all tubing

and wire connections for snug fit. Test fire the unit. Install

upper panels.

Figure 55 – Combustion Air Adjustment with a Manometer to

Set Differential Pressures

Servicing Hot Surface Igniter and Ignition

Module

This pool heater uses a proven hot surface ignition control module

and a hot surface igniter. The hot surface ignition module is not

repairable. Any modification or repairs will invalidate the warranty.

ƽ WARNING: Do not attempt to repair a faulty hot

surface igniter or ignition module. Any modification or

repairs may create hazardous conditions that result in

property damage, personal injury, fire, explosion

and/or toxic gases.

A faulty hot surface igniter or ignition module must be replaced

with an identical part. A specification igniter and ignition control

module for this specific pool heater is available from your local

distributor. Do not use general purpose field replacement ignition

modules or igniters.

Ignition System Checkout

1. Turn “OFF” the gas supply to the pool heater.

2. Turn the electric power “ON”.

3. Program the temperature control to settings above water

temperature or to the highest safe setting.

4. The igniter will cycle on trial for ignition.

5. The ignition module will lock out and turn the alarm light on.

6. Program the temperature control to the desired temperature set

point.

7. Turn “ON” the gas supply.

8. Press the module reset button (located on the front of the unit)

to reset the module.

9. If ignition system fails to operate properly, repair work must be

performed by a qualified serviceperson or installer.

50