Installation and Service Manual

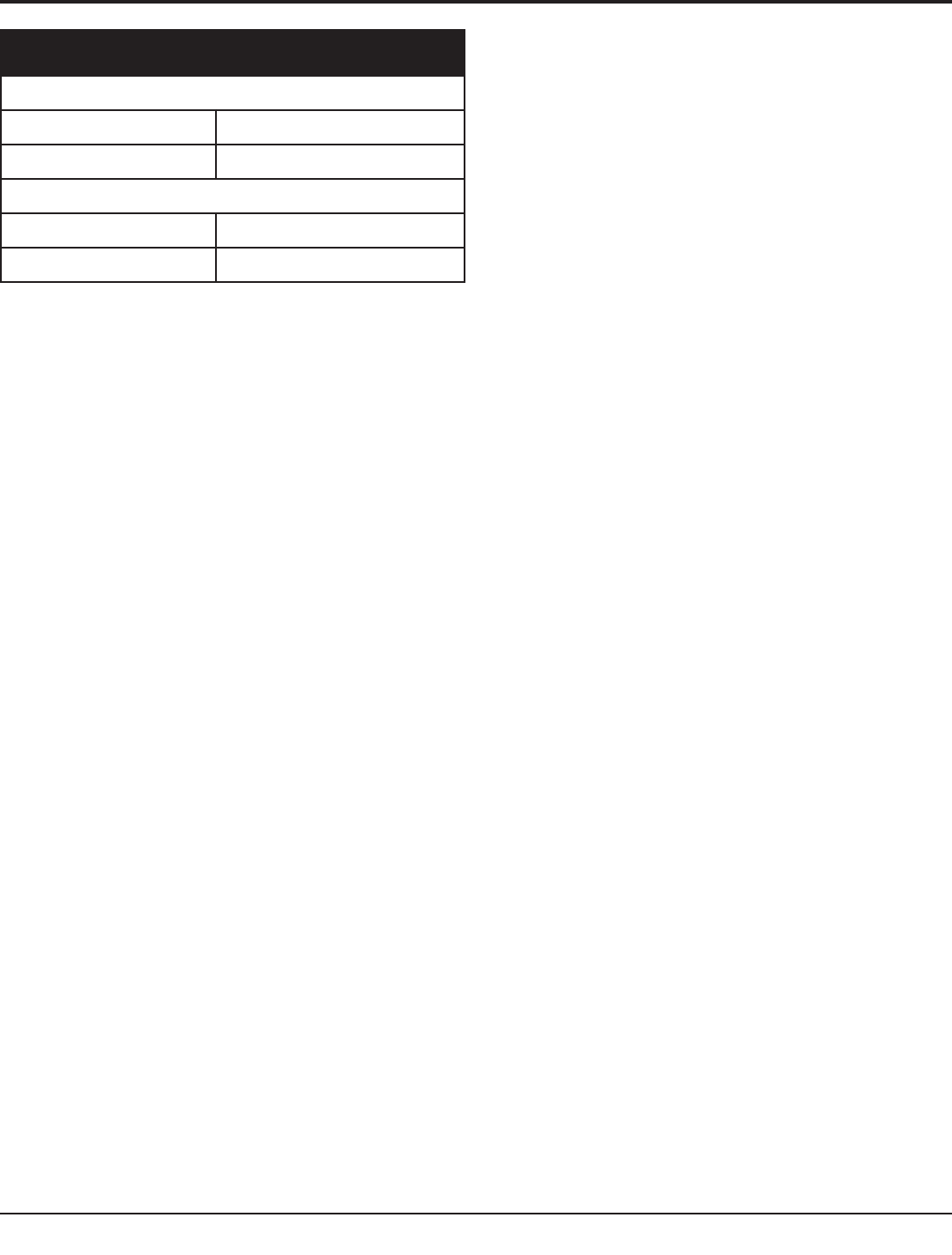

TABLE-L

Net Manifold Pressure

500,000 – 750,000

Natural Gas 1.8" w.c.

LP Gas 4.6" w.c.

990,000 – 2,070,000

Natural Gas 1.2" w.c.

LP Gas 4.6" w.c.

*Net Manifold Pressure equals the measured manifold pressure minus

the chamber pressure. See Figure 31 to measure the Net Manifold Pressure.

POOL HEATER PIPING

INSTALLATION

Install piping from the filter system to the pool heater as shown in

the pool heater piping diagrams. See Figures 34 - 38. Minimum

pipe diameter to and from the installed pool heater to the filter

system piping on models 500,000 - 750,000 Btu/hr is 2" and on

models 990,000 - 2,070,000 Btu/hr the minimum is 2-1/2". The

piping from the filter system to the pool heater may be PVC, CPVC

or Copper Pipe. The piping from the pool heater back to the filter

system will carry water with temperatures in excess of 110°F and

must be CPVC or Copper Pipe. The temperature of the heated

water from the pool heater will be substantially cooled as it is mixed

back into the pool water from the filter system and returned to the

pool. The mix of heated water and pool water from the filtration

system should only be slightly warmer than the pool water before

the connections from the pool heater.

Auxiliary Mixed Water Limit Control

Ensure that the auxiliary 110°F mixed water limit control (and

optional pool supply sensor, if used) are installed in the filter system

piping. Install the auxiliary limit a minimum of three feet

downstream from the point where the heated water from the pool

heater is added to the filtration system. See Figures 34 - 38. The

limit and sensor may be mounted in 3/8" NPT tapped fittings

installed in the filtration system piping or they may be installed

directly into tapped openings in the PVC filter system piping. Turn

off the filter system pump when installing the auxiliary limit and

sensor in the filtration system piping. Tapped openings can be

added to the PVC pipe by first drilling 9/16" pilot holes in the PVC

pipe at least three feet downstream of the point where the heated

water from the pool heater is added to the filter piping. The drilled

pilot holes can now be carefully threaded with a 3/8" NPT taper

tap. After the pipe threads have been cut into the PVC pipe wall, the

limit and bulbwell can be inserted into the tapped openings. Apply

a small amount of a high quality RTV silicone sealant to the threads

to prevent leaks and install the limit and bulbwell into the threaded

openings in the pipe. Install the limit control and bulbwell and

tighten to seal. Do not over tighten either part into the threaded

openings in the PVC pipe. Over tightening can damage the parts

and/or strip the threads cut into the plastic pipe. Install the pool

supply sensor into the bulbwell and connect it to the pool heater

circuit as shown in the wiring diagram for your model. Wire the

limit into the pool heater control circuit as shown in the wiring

diagram. If additional wire length is needed, use 18 GA wire for

distances up to 30 ft. For longer distances, size the wire per Table M,

page 37. Use weatherproof connections for outdoor installation.

Pumped Automatic Bypass

This is a high efficiency pool heater which requires a special

pumped bypass for proper operation. The bypass assembly

supplied with the pool heater includes a pump and a 3-way mixing

valve. All piping to connect the filter system to the pool heater is

made directly to the bypass piping on the pool heater.

Outdoor Operation - Outdoor 3-Way

Automatic Bypass Valve Cover

The pump supplied on the pool heater bypass has a sealed motor

suitable for outdoor installations. When installing the 3-way

automatic bypass valve outdoors, an outdoor valve cover is required.

An outdoor valve cover is supplied with an optional outdoor vent

kit (see Table H, page 26 of this manual).

To install the outdoor valve cover, follow the steps below:

1. Turn off power to the unit.

2. Remove the plastic actuator cover from the 3-way

automatic bypass valve by loosening the screw above the

conduit fitting (Figure 32).

3. Grasp the cover on the screw side and lift the cover up and

away from the valve.

4. Disconnect the wires at the terminal block (if connected).

5. Unscrew the plastic conduit cap from the conduit fitting

(Figure 32) and pull the plastic conduit hose and wires

from the valve.

6. Feed the plastic conduit hose through the opening of the

valve cover end cap (JKD6654) (see Figure. 32) and slide

the end cap approximately one foot up the conduit.

7. Reconnect the wires to the 3-way valve circuit board as

shown in Figure 33.

8. Feed the conduit hose into the conduit fitting and

reinstall the conduit cap.

31