SDC / DHC Hydraulic Components

EN2H-0221GE51 R0808 183

7.3.4.10.1.2 Integral action time Tn

The integral part (adjustment time) determines the dynamic

behaviour of the controller and thus the time required by the

controller to adjust for the actual control deviation. The adjustment

time is independent of the amount of deviation.

Example:

With a sudden flow temperature control deviation of 10 K (e.g.

when the system switches from reduced to daytime operation)

and an I-part setting of 7 minutes, the controller will adjust for the

new (10 K higher) flow temperature after the set time.

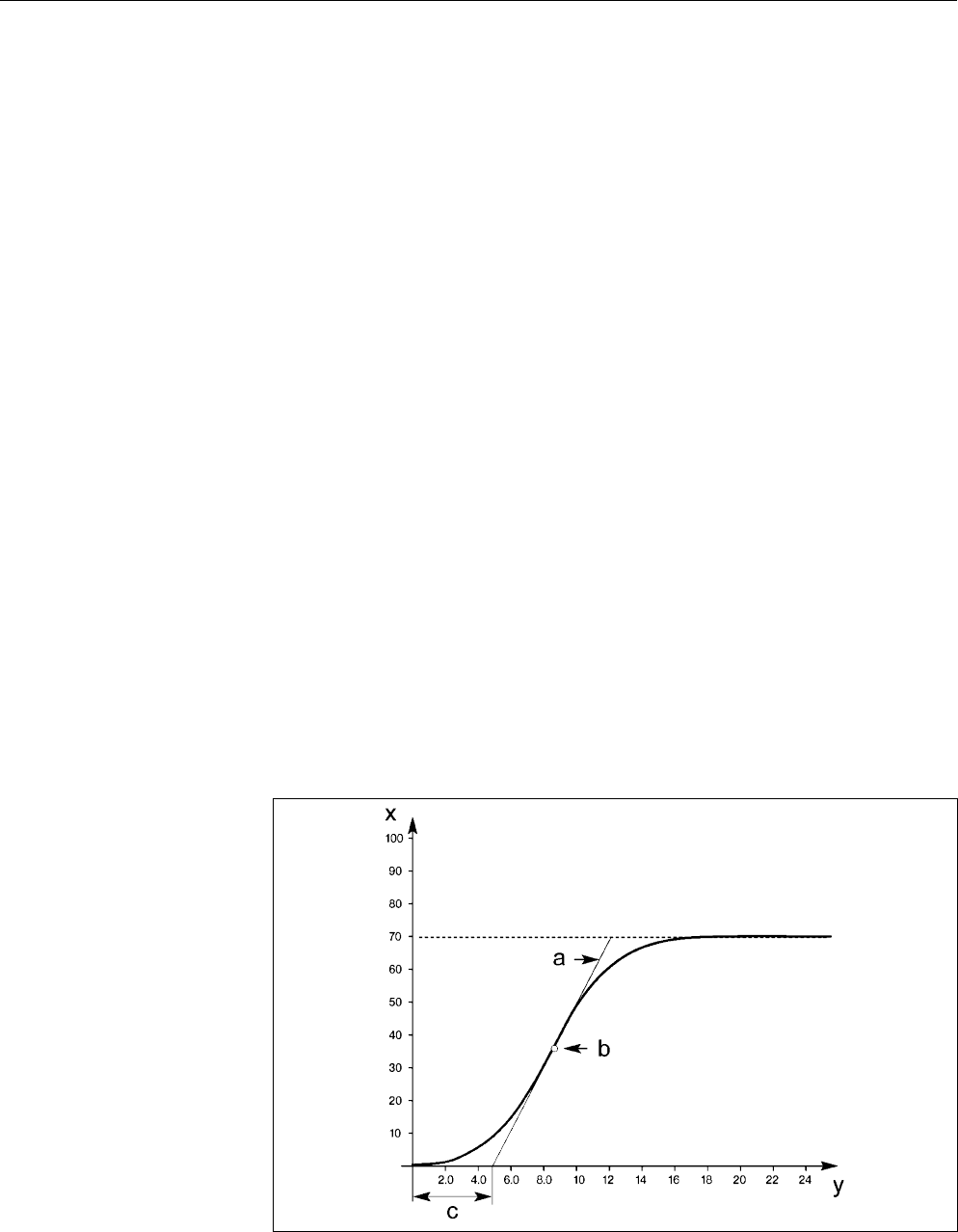

The adjustment time can be determined through the Ziegler-

Nichols method. The mixed heating circuit is closed, initially, and

the heat generator is taken to the maximum temperature for the

heating circuit concerned. As soon as half of all consumers at the

circuit to be measured have been opened, the mixer is fully

opened from cold condition (room temperature) by means of the

relay test function. The heat-up curve, i.e. the temperature

progression over time following this action, shows an inflection

point. The crossing of the tangent through that point and the time

axis is the delay time. This value multiplied by the factor 3.3 is the

optimum integral action time for this heating circuit.

NOTE